Operation

Additive sprinkling

BA RD24_RD28 en us 06

85

3.08 Additive sprinkling

General The additive sprinkling enables a moistening of the wheels with a

separating compound. This prevents that bitumen sticks on tyres when

laying blacktops. This is the only way to make a neat and even covering.

The emulsion may only be mixed of parting agent concentrate and water

according to the indications of the parting agent producer (Observe

regulations for environment protection).

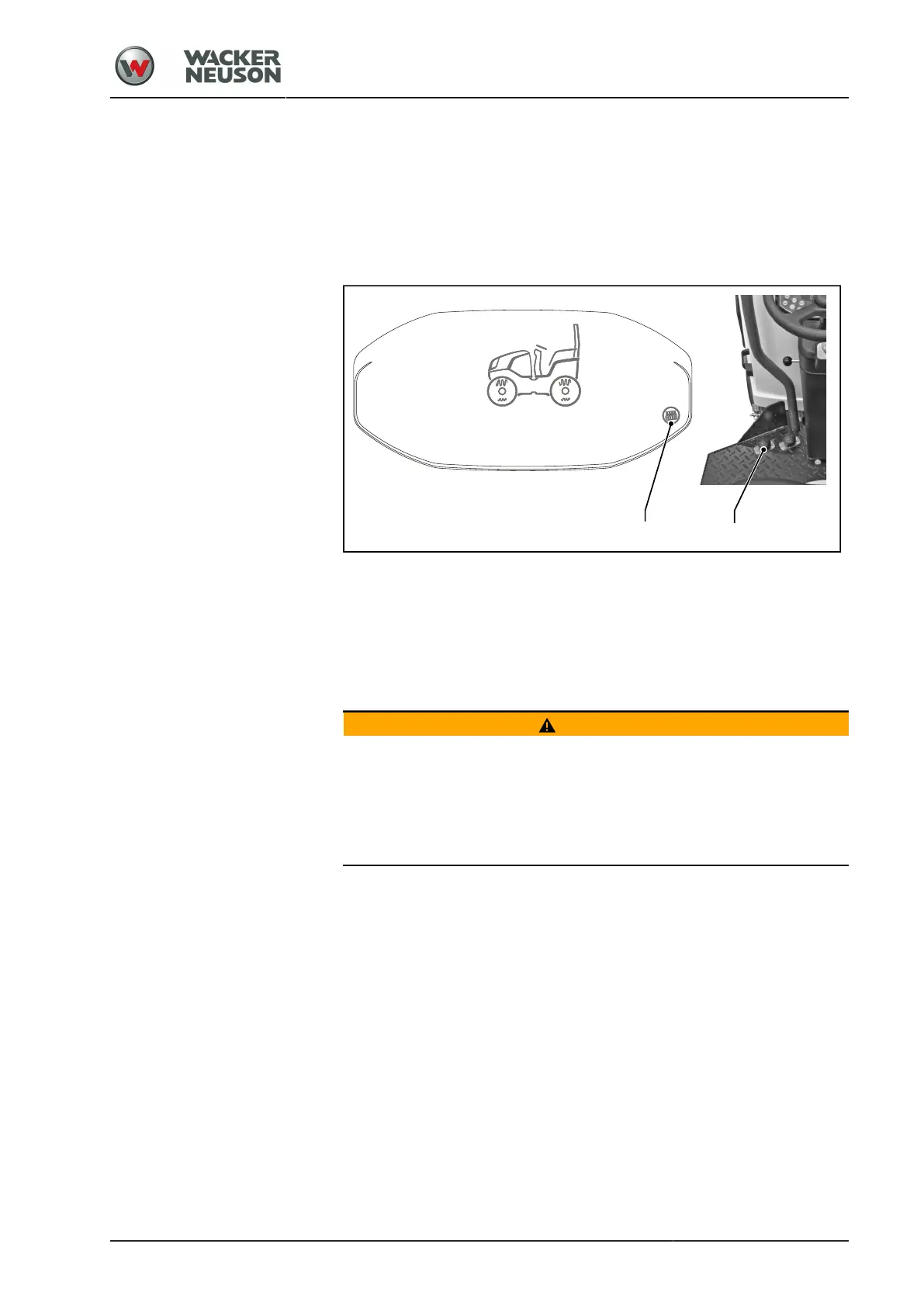

Additive sprinkling

The additive sprinkling is switched on and off using the switch [318] or

[380]. As long as the switch is pressed, the tyres are sprinkled.

The frequency of sprinkling depends on the temperature of the tyres.

Cold tyres must be moistened more often than warm ones. Prior to

driving on hot blacktops take care that the running surfaces of the wheels

are clean and sufficiently moistened.

On risk of frost

WARNING

Uncontrolled movements!

Unintentional rolling away of the machine can lead to serious injuries

or death.

■

Secure machine against rolling away.

002-21

After the long standstill period in the winter we recommend, to drain and

clean the container for the additive sprinkling.

If strongly diluted separating compound is used, the container and the

pump for the additive sprinkling must be drained when frost is likely.

Empty additive sprinkling

system

1. Remove pressure hose from hose connection piece.

2. Switch on the pump until intake pipe and pump is free of fluids.

3. Mount pressure hose on hose connection piece.

Loading...

Loading...