Phenomenon: Running jitter, slow

response

Phenomenon: smooth

operation and slow response

Phenomenon: smooth

operation and fast response

Note: The above curves only show the effect of the parameters, not the real running curves.

5.1.4 Torque disturbance observation

Disturbance observer can reduce the influence of external disturbance on servo system and improve the

anti-disturbance ability by detecting and estimating the external disturbance torque of the system and

compensating the torque command.

If the soft mode is selected in the auto-tuning mode, the disturbance observer will be closed automatically, and the

gain of the disturbance observer will not change. If the fast positioning or fast positioning (control overshoot) is

selected, the disturbance observer will be opened automatically, and the gain of the disturbance observer will be

modified to 85. The relevant parameters of this function no need to be set manually by users.

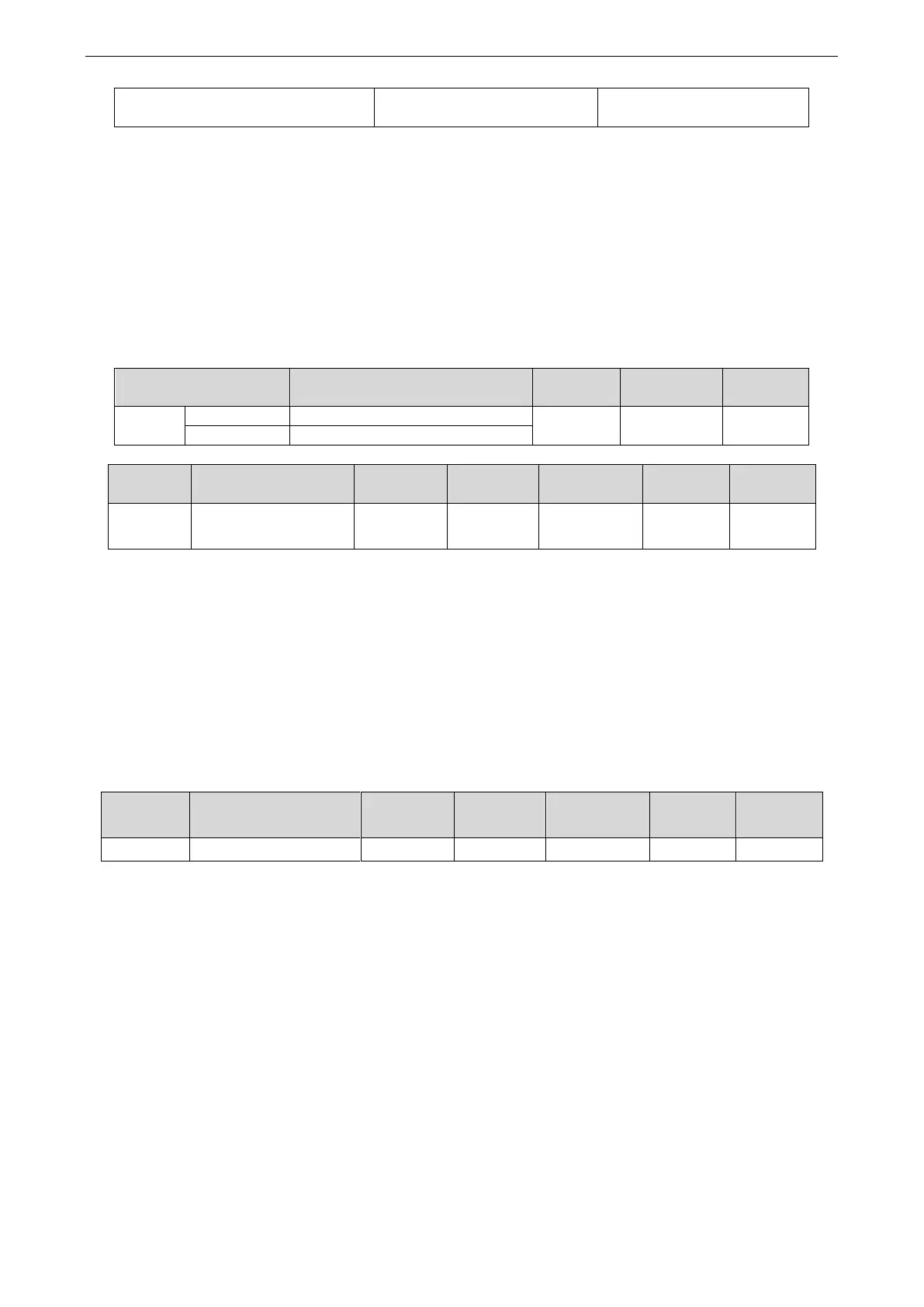

Turn-off of disturbance observer

Turn-on of disturbance observer

Disturbance observer

gain

5.2 Rotary inertia presumption

5.2.1 Overview

Rotational inertia estimation is the function of automatic operation (forward and reverse) in the driver and

estimate the load inertia in operation.

Rotational inertia ratio (the ratio of load inertia to motor rotor inertia) is a benchmark parameter for gain

adjustment, and it must be set to the correct value as far as possible.

5.2.2 Notes

Occasions where inertia cannot be presumed

➢ Mechanical systems can only operate in one direction

The occasion where inertia presumption is easy to fail

➢ Excessive load moment of inertia

➢ The running range is narrow and the travel is less than 0.5 circles.

➢ The moment of inertia varies greatly during operation.

➢ Mechanical rigidity is low and vibration occurs when inertia is presumed.

Notes of Inertia Presumption

➢ Since both directions are rotatable within the set range of movement, please confirm the range or

direction of movement; and ensure that the load runs in a safe journey.

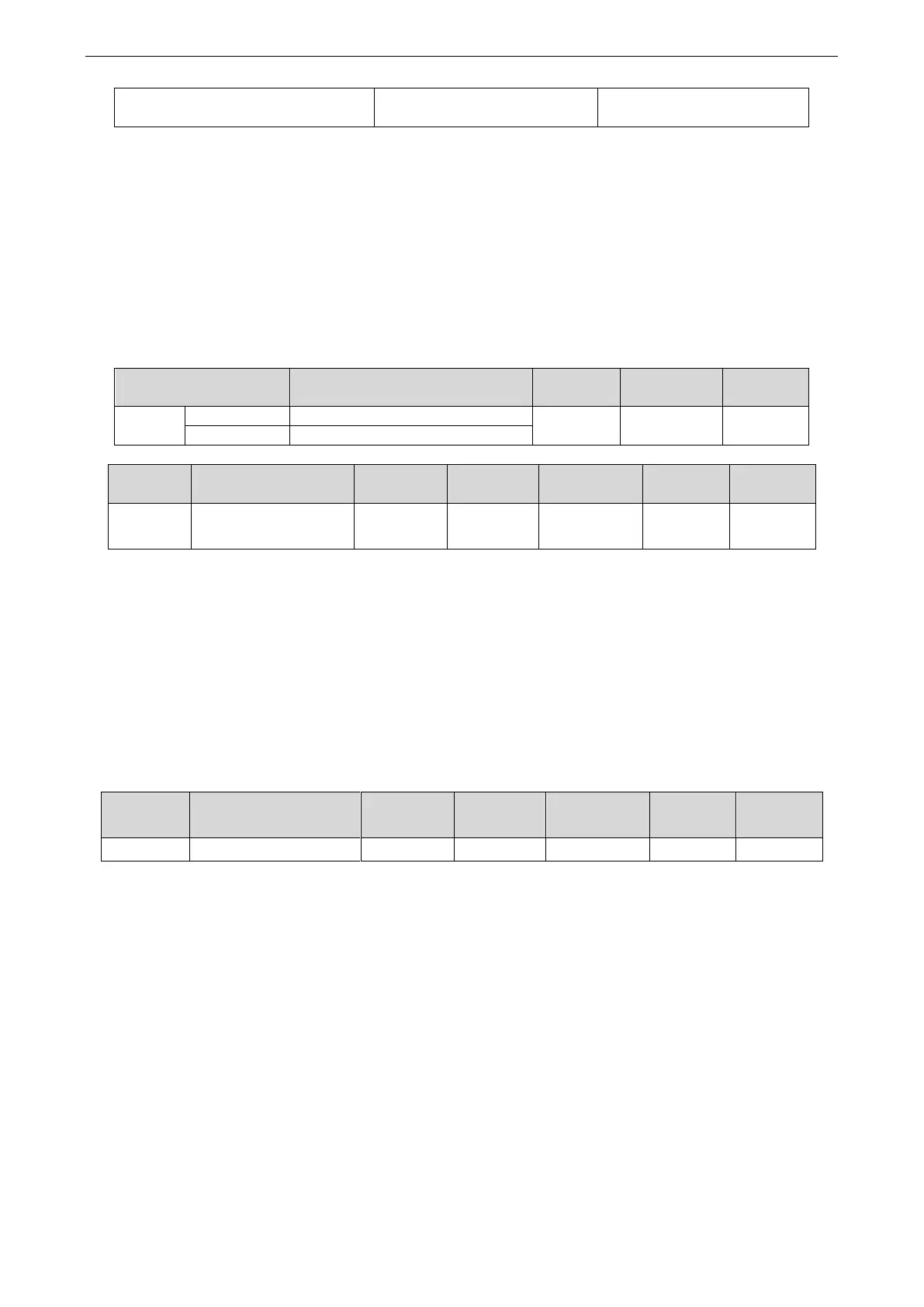

Loading...

Loading...