3 ENGINE 3 ENGINE

EF494T TM 06/2011 edition

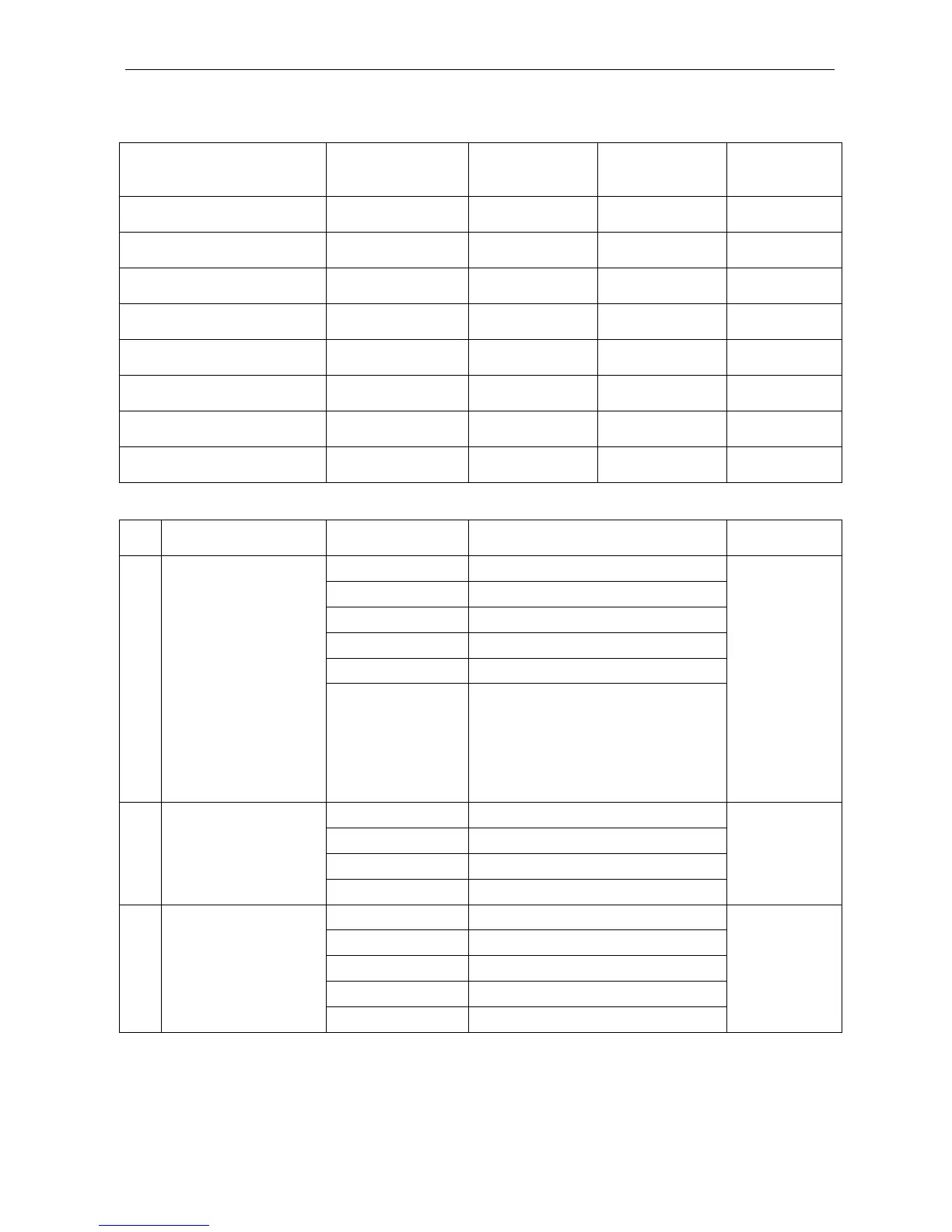

3.5.18 Tightening torque tables

Tightening

torque

N•m (kgf•m )

Application of

lubricating oil

(to

threads/seat)

85.3 to 91.1

(8.7 to 9.3)

44.1 to 49.0

(4.5 to 5.0)

83.3 to 88.2

(8.5 to 9.0)

Bearing cap mounting bolt

93.2 to 98.1

(9.5 to 10.5)

Crankshaft pulley mounting

bolt

112.7 to 122.7

(11.5 to 12.5)

Fuel valve retainer mounting

bolt

24.4 to 28.4

(2.5 to 2.9)

Fuel pump drive gear

mounting bolt

High-pressure fuel line

tightening nut

29.4 to 34.3

(3.0 to 3.5)

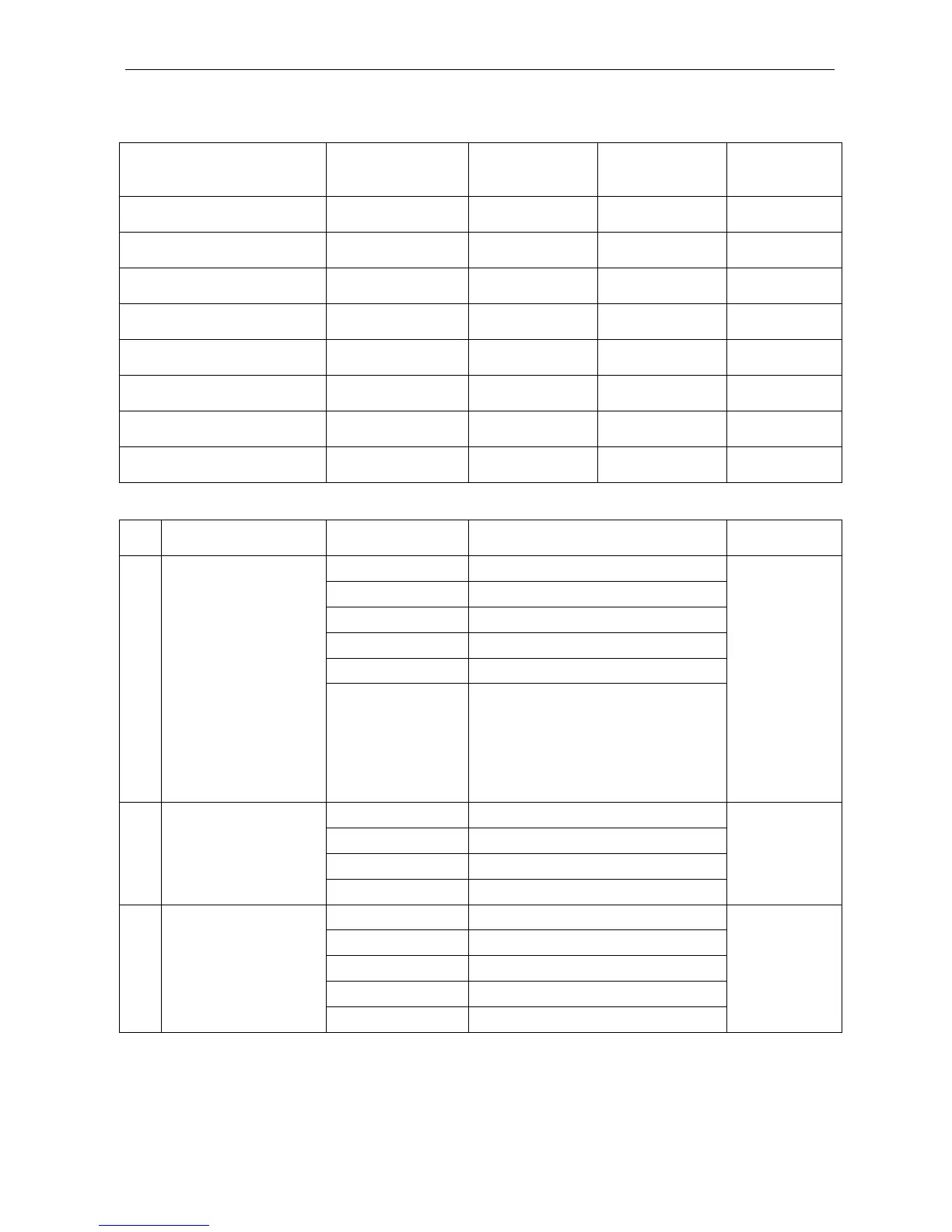

Bolts and nuts for general use (lubricating oil not applied)

Tightening torque

N•m (kgf•m )

Hexagon head bolt

(7T) and nut

If these kinds

of bolts and

nuts are

tightened for

any aluminum

part, use 80%

of the torque

values

indicated here.

For 4T bolts

and lock nuts,

use 60% of the

torque values

indicated here.

22.6 to 28.4 (2.3 to 2.9)

44.1 to 53.9 (4.5 to 5.5)

127.5 to 147.1 (13 to 15)

215.7 to 235.4 (22 to 24)

12.7 to 16.7 (1.3 to 1.7)

19.6 to 25.4 (2.0 to 2.6)

24.5 to 34.3 (2.5 to 3.5)

39.2 to 49.0 (4.0 to 5.0)

49.0 to 58.8 (5.0 to 6.0)

Loading...

Loading...