3 ENGINE 3 ENGINE

EF494T TM 06/2011 edition

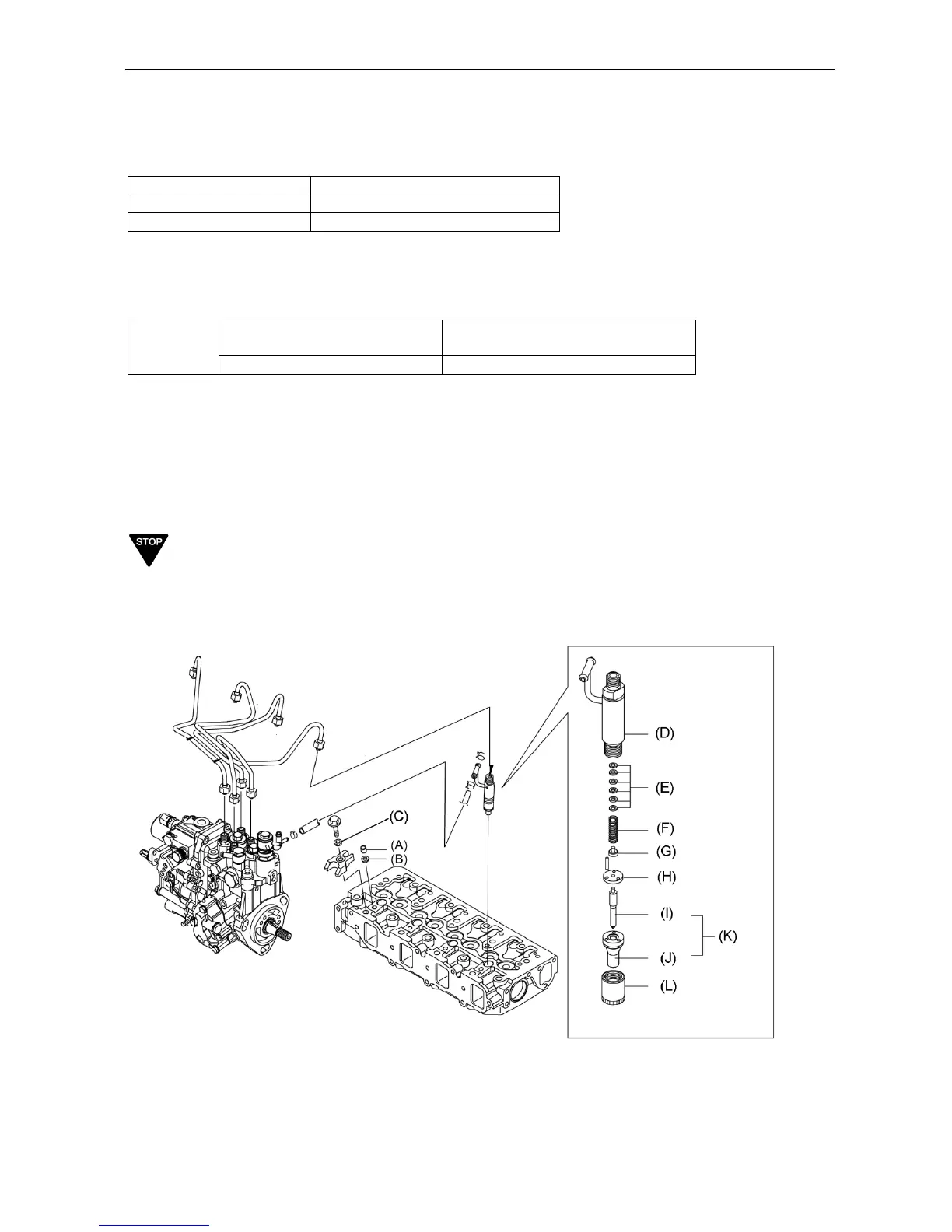

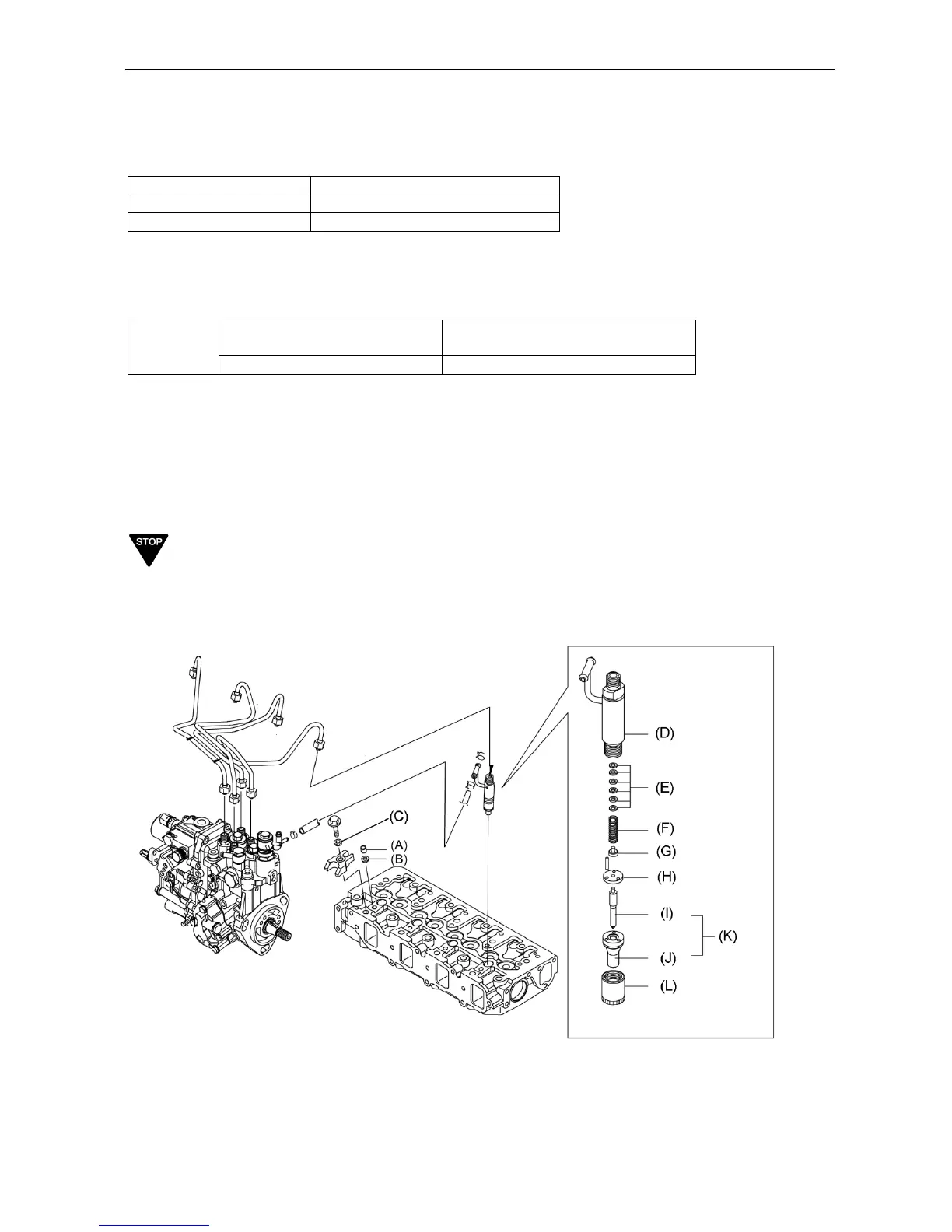

3.1.6 Fuel injection nozzles

The use of Yanmar's original direct-injection combustion chamber plus hole valve

ensures the ideal mixing of fuel with air, thereby enabling complete combustion.

Hole valve (5 injection holes)

Initial injection pressure

<Precautions for assembling the injection valve>

(1) The nuts and case nuts used to assemble the fuel injection valve should be

tightened to the specified torque.

Mounting bolt for fuel injection

valve retainer(M8 x 1.25)

24.4 to 28.4N•m (2.3 to 2.9kgf•m)

39 to 44N•m (4 to 4.5kgf•m)

Note: Do not lubricate the bolt threads and the nut face.

(2) When removing the injection valve, make sure that protector (A) and packing

(B) do not remain in the cylinder head. Replace them whenever reinstalling

the injection valve.

(3) An increase of 0.1 mm in thickness of the pressure adjusting shim section will

result in an increase of about 19 MPa in injection pressure.

IMPORTANT

When the install the fuel injection nozzle, apply the molybdenum grease to the

outside of the (D).

The flat surface of the washer (C) must be faced upward.

(A) Protector

(B) Packing

(C) Washer

(D) Nozzle holder

(E) Pressure adjusting

shim section

(F) Nozzle spring

(G) Nozzle spring seat

(H) Valve stop spacer

(I) Nozzle valve

(J) Nozzle body

(K) Nozzle

(L) Nozzle mounting nut

Tightening torque: 39 –

44 N•m (4 – 4.5 kgf•m)

Loading...

Loading...