2 DISASSEMBLY OF COMPONENTS 2 DISASSEMBLY OF COMPONENTS

EF494T TM 06/2011 edition

2.5.2 Docking

(1) Remove the old liquid gasket on mating

surface of engine and clutch housing. Apply

Three bond 1215 or equivalent type of liquid

gasket.

WARNING

The disassembled machine is very unstable. Be

careful not to let it fall over and be sure to attach a

wedge to the front axle swing section.

IMPORTANT

If clutch and pressure plate was disassembled,

align clutch disc as described in “4 Clutch” in this

manual.

(2) Move the main shift lever to N and the PTO

to the shift position. Dock the machine by

turning the rear axle PTO shaft by hand.

Note: The shaft is docked to the clutch plate

when the PTO shaft does not turn any more.

(3) Move the main shift lever and the sub-shift

lever to ON. Insert a screwdriver though the

view port on the flywheel and complete the

docking procedure by turning the flywheel.

(4) After docking the machine, reinstall the parts

by reversing the procedure described in

“2.5.1 Separation”.

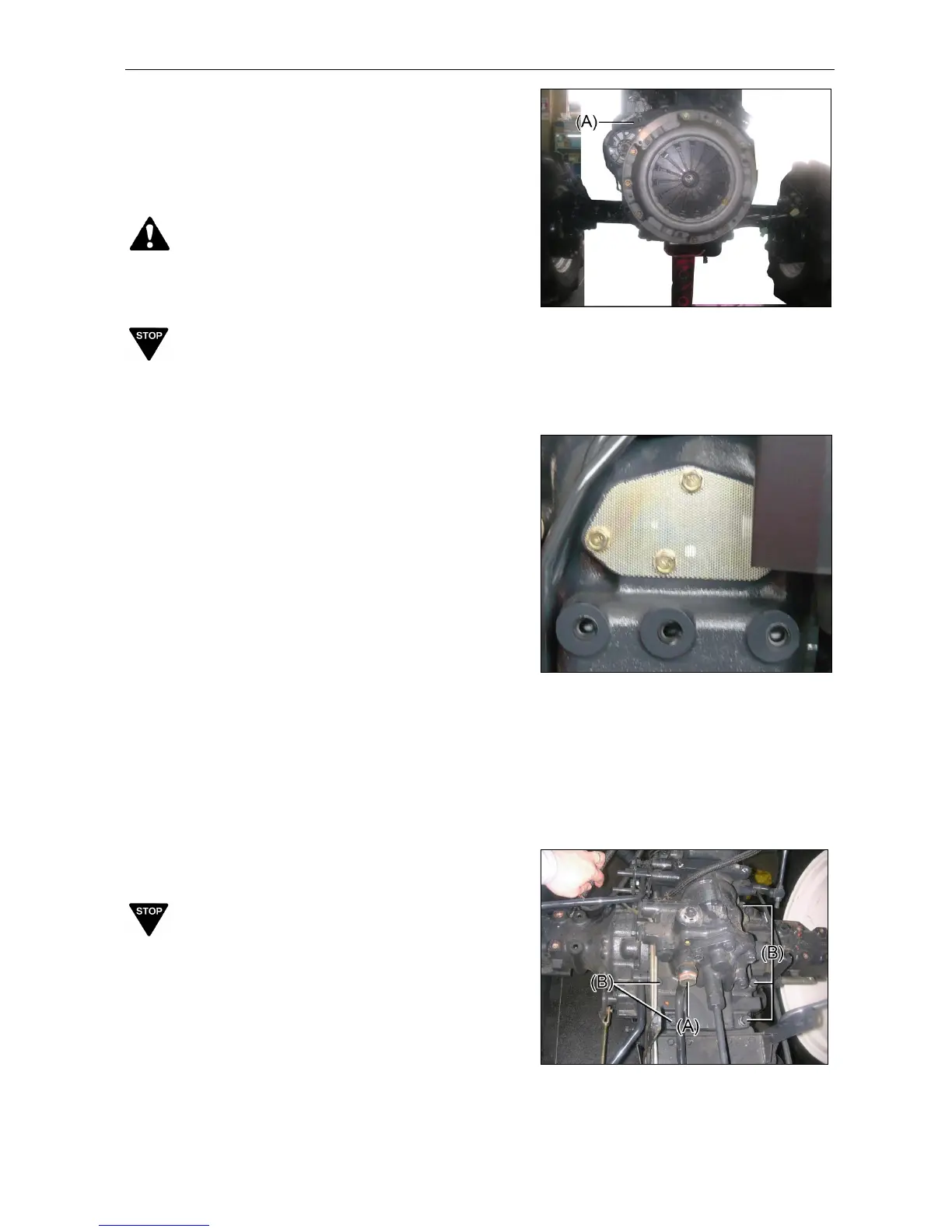

View port on the flywheel

2.6 TRANSMISSION

2.6.1 Separating the hydraulic cylinder case

(1) Remove the seat stay. See “2.4 REMOVING

THE SEAT STAY”.

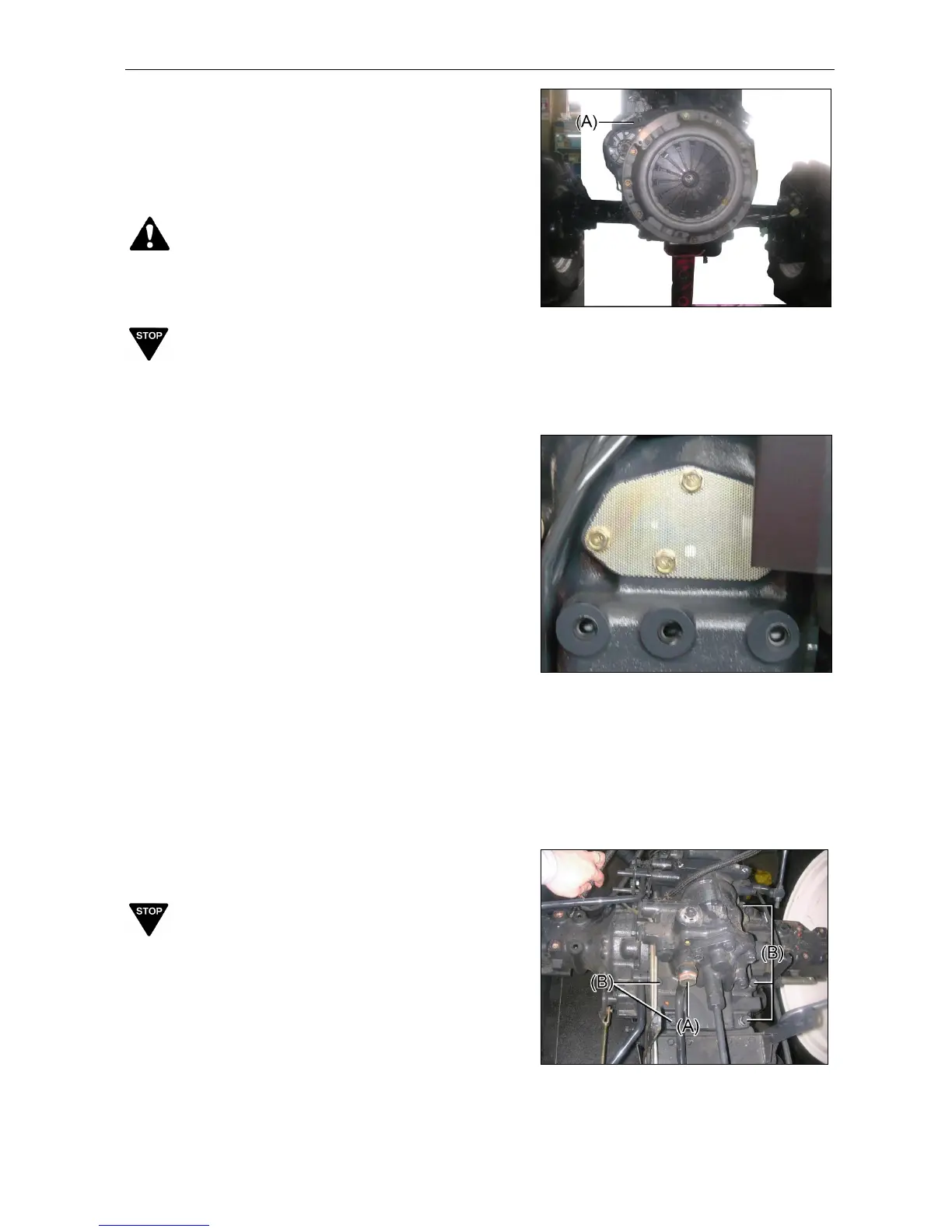

(2) Remove the bolt (A), and disconnect the

hydraulic pipe.

IMPORTANT

Replace the copper packing with a new one.

(3) Remove the 12 pieces of M12x35 bolts (B).

Loading...

Loading...