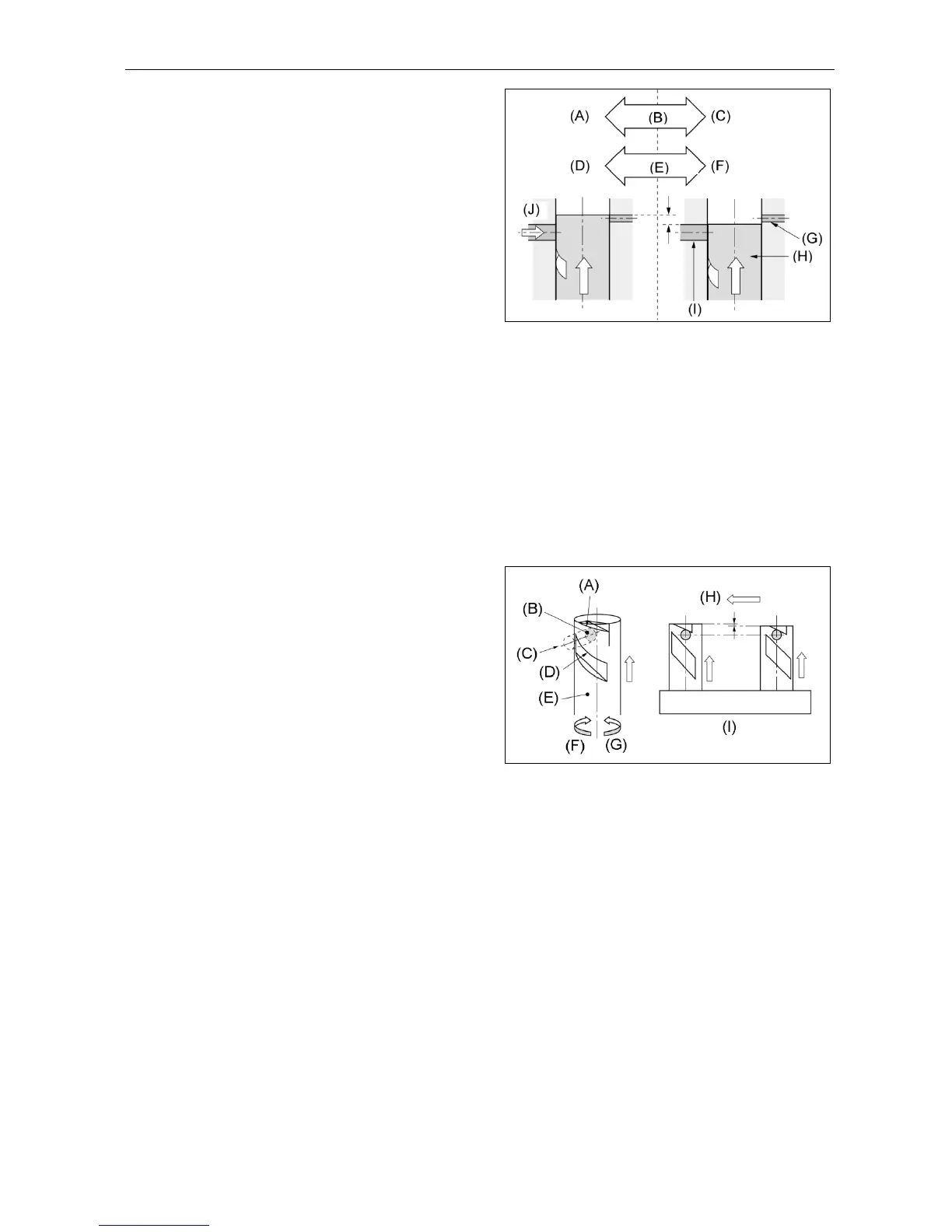

3.2.3 Revolution timer

Clean exhaust gas is assured over the entire

range of engine speeds by changing the fuel

injection timing according to the engine speed.

At low engine speed

Fuel injection is less affected by the viscosity of

fuel and starts after the sub-port has been

closed. (At a low engine speed, the injection

timing is delayed.)

At high engine speed

Fuel injection is affected by the viscosity of fuel

and starts even if the sub-port is not closed.

(A) Low

(B) Engine rpm

(C) High

(D) Delay

(E) Timing

(F) Advance

(G) Sub-port

(H) Plunger

(I) Main port

(J) Load timer

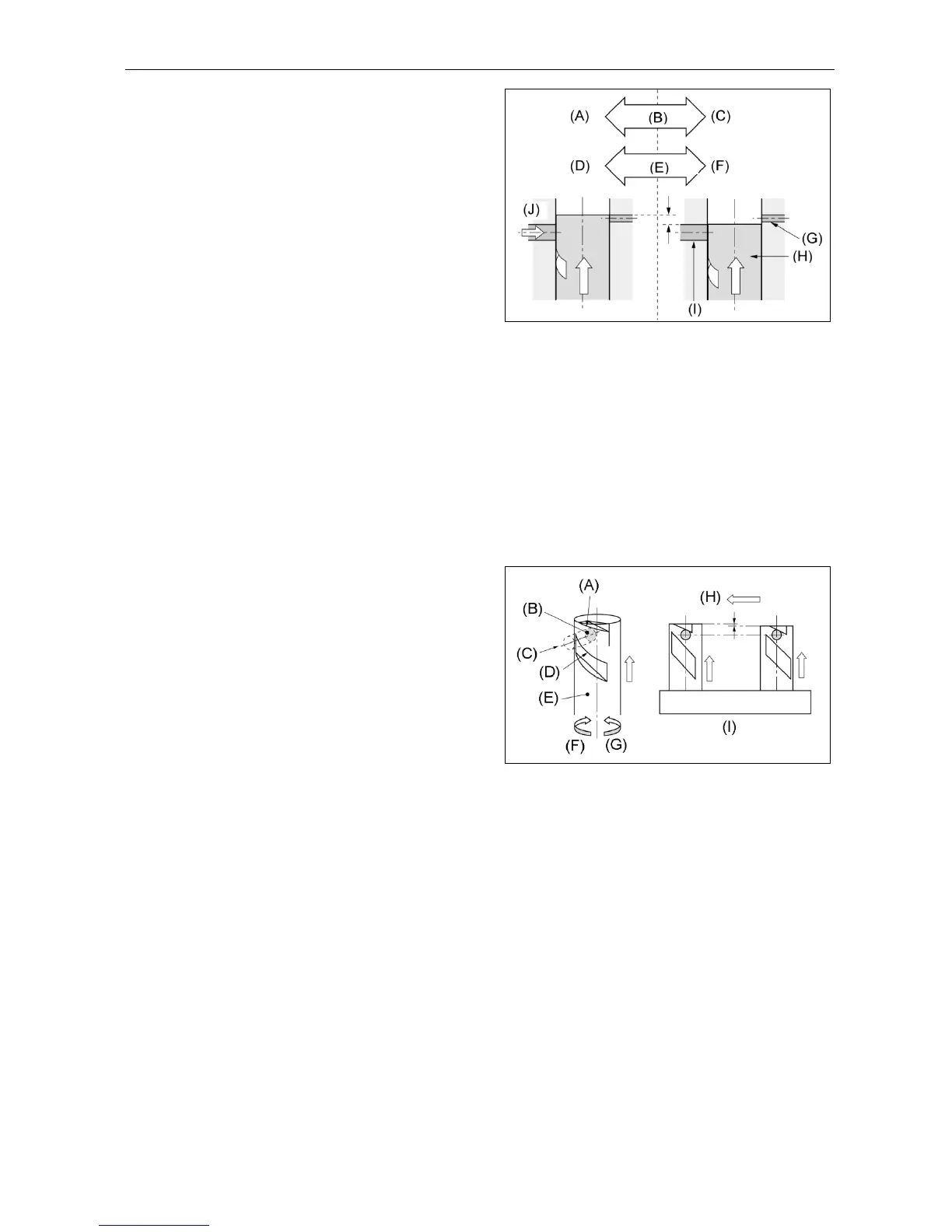

3.2.4 Load timer

The fuel injection timing is changed in

accordance with the load condition of the engine,

thereby optimizing the injection timing over the

entire range from the no-load condition to the full-

load condition and making exhaust gas clean.

When the upper leading part of the plunger goes

beyond the main port, fuel injection starts.

Once load is applied, the plunger starts operating

and the stroke length of the upper part of the

plunger increases. The fuel injection timing is

delayed accordingly. (The injection timing is

delayed when load is applied.)

(A) Upper leading part

(B) Main port

(C) Fuel

(D) Main leading part

(E) Plunger

(F) Fuel increase

(G) Fuel decrease

(H) Load increase

(I) The injection timing is delayed and the stroke

length of the upper leading part increases as the

load increases.

Loading...

Loading...