5 . MAINTENANCE AND ADJUSTMENTS

5.24

Challenger MT500B EU

5.17 - TYRES

5.17.1 - Dual rear wheels

In general, dual rear wheels should be used for soil bearing

capacity work (surface treatment and work) The correct

dual rear wheels should be chosen according to the four

following criteria:

1. Soil bearing capacity

2. Tractive effort (narrow wheels)

3. Overall dimensions (2m50 for road gauge)

4. Type of tyre

CAUTION: The wrong choice of dual wheels

has a direct influence on the mechanical com-

ponents and the wheel discs of the tractor.

The use of dual wheels should be avoided

when making strong tractive efforts, even momentar-

ily (tree-stump extraction, pulling out a bogged-down

tractor, etc.).

5.17.2 - Use

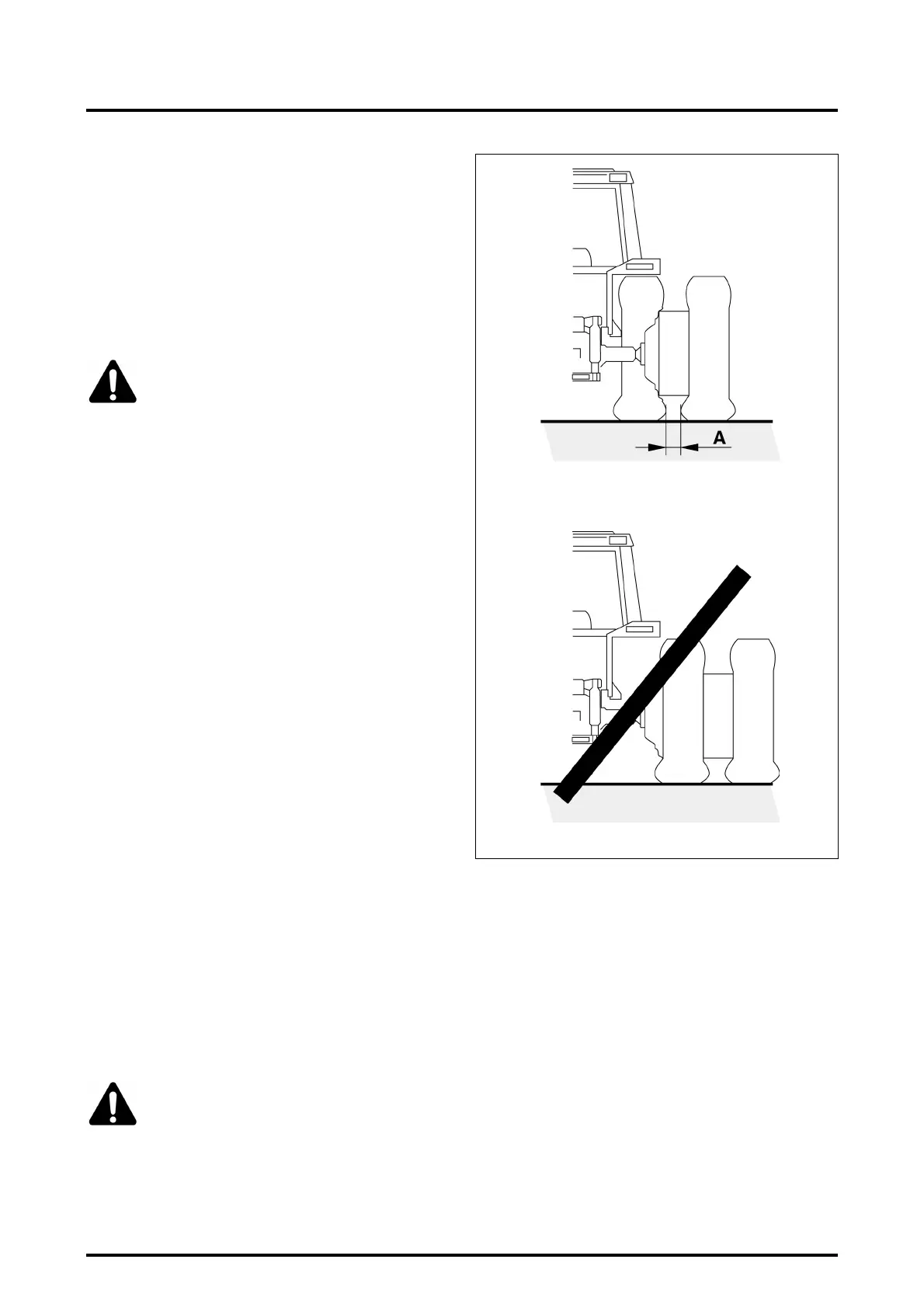

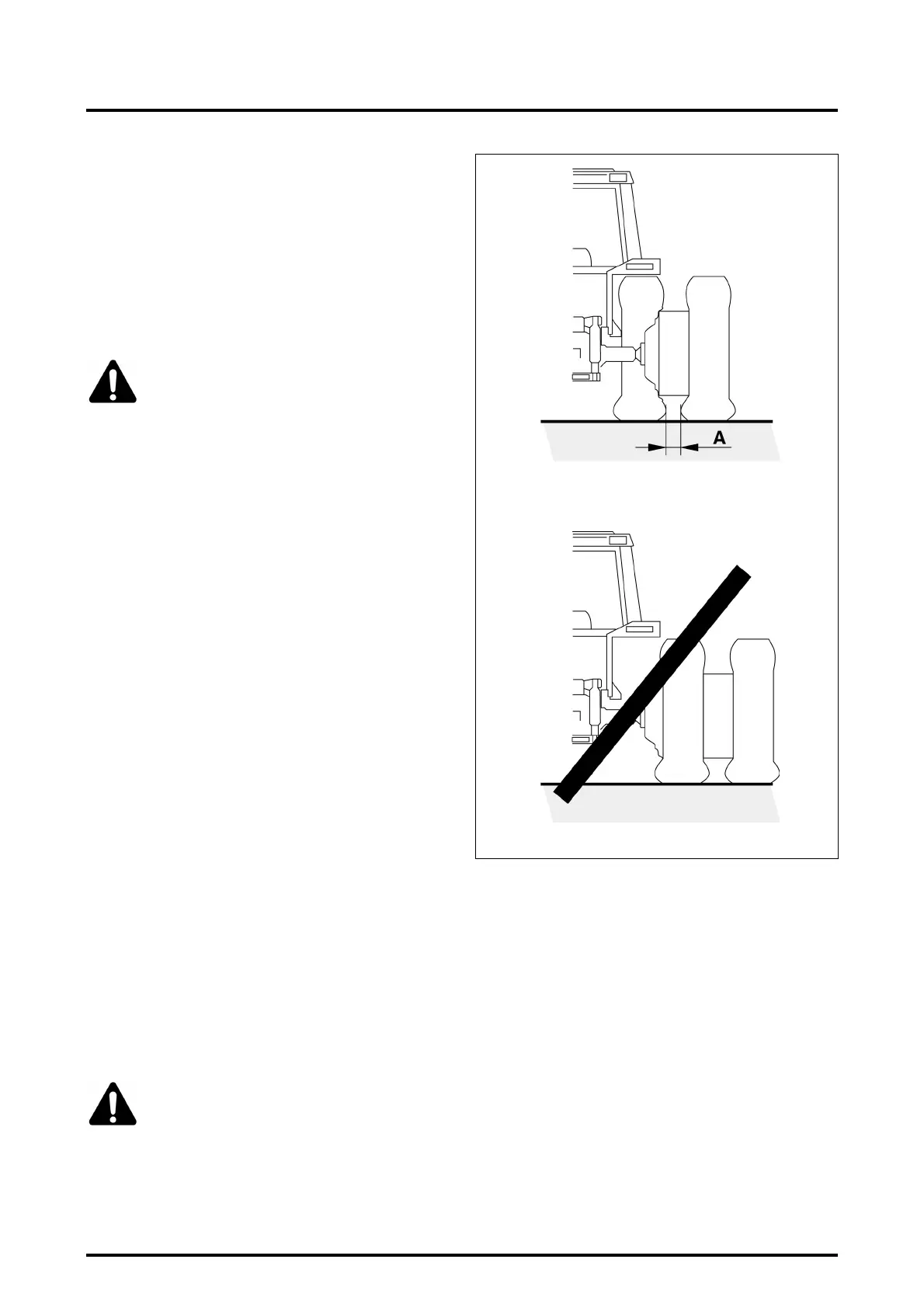

Set the tractor to minimum track (Fig. 42).

The use of very wide tyres on dual wheels is not recom-

mended.

The most efficient dual wheels arrangement uses two

tyres of the same specifications.

1. When fitting dual wheels with tyres of different

widths, the wider wheel must be fitted inside.

When fitting dual wheels with tyres of the same width,

the tyre which is more worn must be fitted on the out-

side.

2. It is preferable to use wide tyres or low pressure tyres

instead of twin wheels.

NOTE: Dual wheels do not double the load capacity of

the tractor.

The minimum distance allowed between the tyres is 100

mm (A Fig. 42).

In clay soil, this distance should be increased in proportion

to the tyre size. Example:

13.6-28 - Distance 130 mm

16.9-38 - Distance 160 mm

20.8-42 - Distance 200 mm

5.17.3 - Wheel bolts

Check the tightening torque after the first two hours of use

following fitting and every day thereafter.

Liquid ballasting

Steering and braking performance can be considerably af-

fected by attaching implements. To maintain the required

ground contact pressure, ensure that the tractor is ballast-

ed correctly. Advice is available from your local Dealer.

• Tyres with tubes:

CAUTION: When preparing a calcium chloride

solution for liquid ballasting the tractor tyres,

NEVER pour water on to the calcium chloride;

this can produce chlorine gas which is toxic

and explosive. This can be avoided by slowly adding

calcium chloride flakes to water and stirring until they

are dissolved.

• Tubeless tyres

Use a glycol based liquid containing corrosion inhibiting

agents other than nitrites (Na No

2

). Example: Agrilest,

Castrol, Lestagel, Igol, etc.

5.17.4 - Inflation pressure

0.2 bar less on the outer tyres.

5.17.5 - Pressure under load (bar) (psi)

Check the tyre pressures every 100 hours. Tyre pressures

vary according to make type, load and speed as well as to

the type of work to carry out.

Refer to the inflation tables issued by the tyre manufactur-

ers.

The relationship between the sizes of the front and rear

on 4-wheel drive tractors is most important and only

compatible sizes must be used. The compatibilities are

given in chapter 6.

Fig. 42

Z2-590-05-03

Loading...

Loading...