7 . ACCESSORIES AND OPTIONS

7.17

Challenger MT500B EU

7

7.3.5 - Working operation

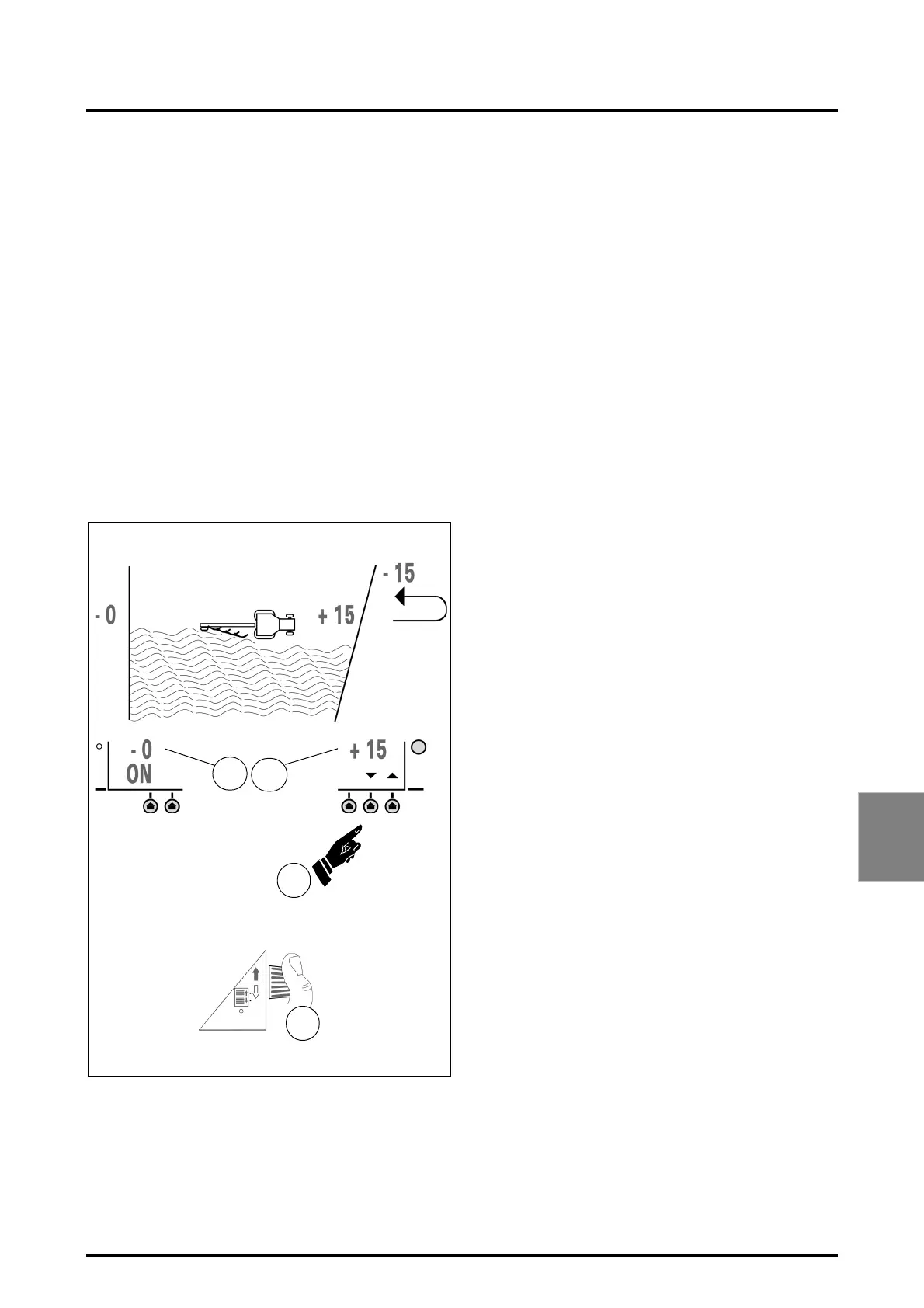

(Fig. 18, Fig. 19)

In the "furrow start" phase, the front plough share pene-

trates into the earth and the rear depth wheel initiates a

partial lowering (ref. K, set to L, Fig. 16).

When the last share reaches the ground, the rear depth

wheel is lowered to its working position ref. 23.

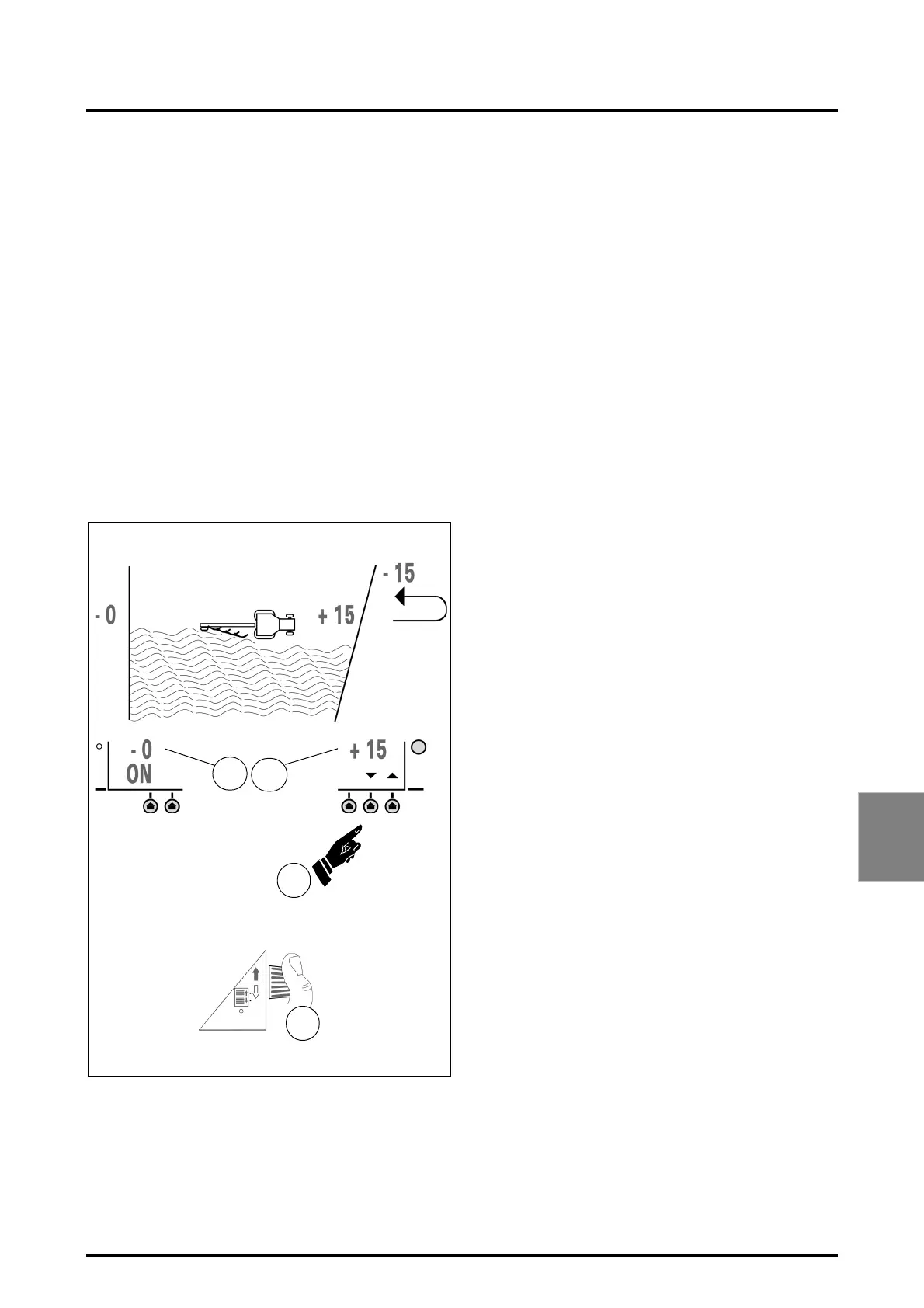

Windows 16 and 17 (Fig. 19) indicate the plough length cor-

rection applicable to the next furrow starts or ends.

To change the values, select the window using keys 6-1 or

6-2 and adjust knob 14.

E.g.: Field start correction (- 0) (straight headland furrow).

Field end correction (+ 15) (point headland furrow).

The (+/-) values are inverted at each end of the field after

the plough is lifted (on the headland furrow).

In the working position, windows 16 and 17 are displayed

automatically at the end of the field.

NOTE: If the field is rectangular, the correction values in

windows 16 and 17 must be set to "0".

7.4 - GLOSSARY

Working mode:

When the "Dual Control" is switched to this mode, the

plough depth wheel repeats the lifting movements, com-

plying with the amplitude and the phase of the lifting move-

ments.

The depth wheel position can be corrected by operating

the manual control of the spool valve.

Furrow start mode:

When a transport/work transition is made, the system

switches to partial lowering mode.

The following steps are carried out: Lowering of the linkage

and partial lowering of the plough depth wheel to the

stored partial lowering setting value.

The lowering of the linkage continues; the plough depth

wheel height does not change as long as the equivalent

distance covered by the tractor (first to last share) is less

than the set and stored value called Furrow start plough

length.

Furrow end mode:

When a work/transport transition is made, the system

switches to partial lifting mode.

The following steps are carried out: Lifting of the linkage

and partial lifting of the plough depth wheel to the stored

partial lifting setting value.

The lifting of the linkage continues; the plough depth wheel

height does not change as long as the equivalent distance

covered by the tractor (first to last share) is less than the

set and stored value called “Furrow end plough length”.

Headland furrow mode:

The linkage is raised to maximum high position. (value de-

termined by the high position potentiometer) and the

plough depth wheel is in the stored high position.

Plough length:

This is representative of a "distance value" from the tractor

rear wheel axle to the plough depth wheel axle.

This setting determines the partial lowering and lifting tim-

ing for the plough depth wheel.

Optimum setting:

Setting obtained from the plough length values which pro-

vide best penetration into the earth of first and last share

on a same furrow start line (X. Fig. 18).

Fig. 19

16

17

2 1

6

14

Loading...

Loading...