Loading...

Loading...

Do you have a question about the Delta DVP-ES3 Series and is the answer not in the manual?

| Series | DVP-ES3 Series |

|---|---|

| Category | Controller |

| Program Capacity | Up to 32K steps |

| Input Voltage | 24V DC |

| Power Supply | AC or DC (depending on model) |

| I/O Points | Up to 256 points |

| Digital Inputs | Up to 128 points |

| Digital Outputs | Up to 128 points |

| Communication Ports | RS-232, RS-485 |

| Programming Language | Ladder Diagram |

| Operating Temperature | 0°C to 55°C |

| Storage Temperature | -20°C to 70°C |

| Humidity | 5% to 95% RH, non-condensing |

| Pulse Output | 2 points 10kHz / 2 points 20kHz (depending on model) |

Provides an overview of the DVP-ES3 Series PLC's functions, devices, and troubleshooting.

Details high efficiency, I/O support, program capacity, and IEC 61131-3 compliance of the CPU module.

Outlines functional and electrical specifications, programming languages, and instruction execution speed.

Covers general specs, profiles, and electrical specifications for digital I/O modules.

Details general specs, profiles, and electrical specifications for analog I/O modules.

Guides through installing and uninstalling ISPSoft software, including system requirements.

Explains the process of installing and uninstalling COMMGR software.

Introduces hardware components, system limits, necessary, and optional components for DVP-ES3 PLC.

Provides instructions for installing the PLC and modules in a control box or on a DIN rail.

Covers general warnings and notes for wiring I/O modules, including cable specifications.

Details precautions for connecting AC and DC power cables, including grounding methods.

Explains device naming conventions, I/O storage structure, and PLC actions related to device types.

Details functions of CPU devices like values, constants, floating-point numbers, relays, timers, and counters.

Outlines steps for project creation, including hardware, network, programming, and testing phases.

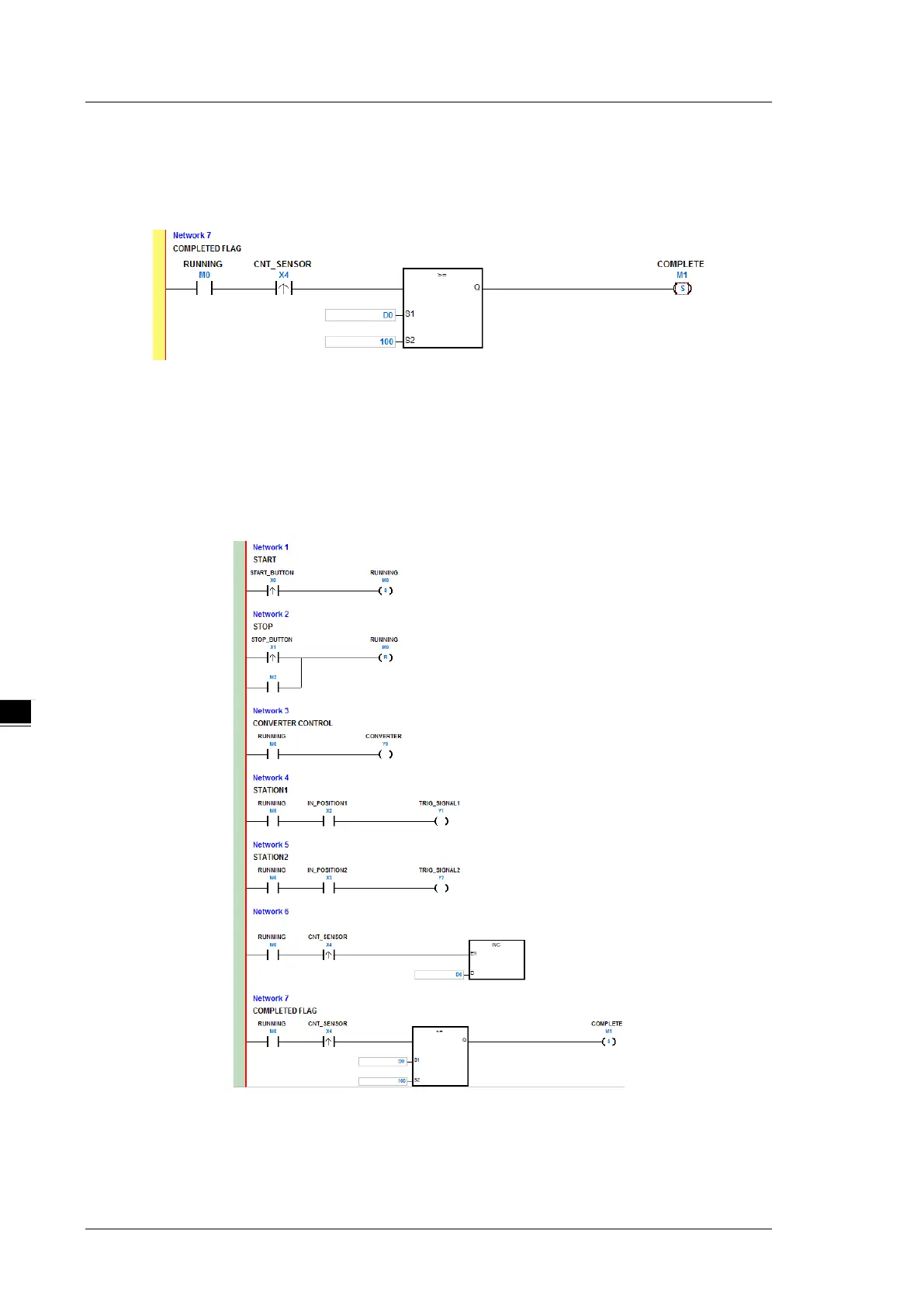

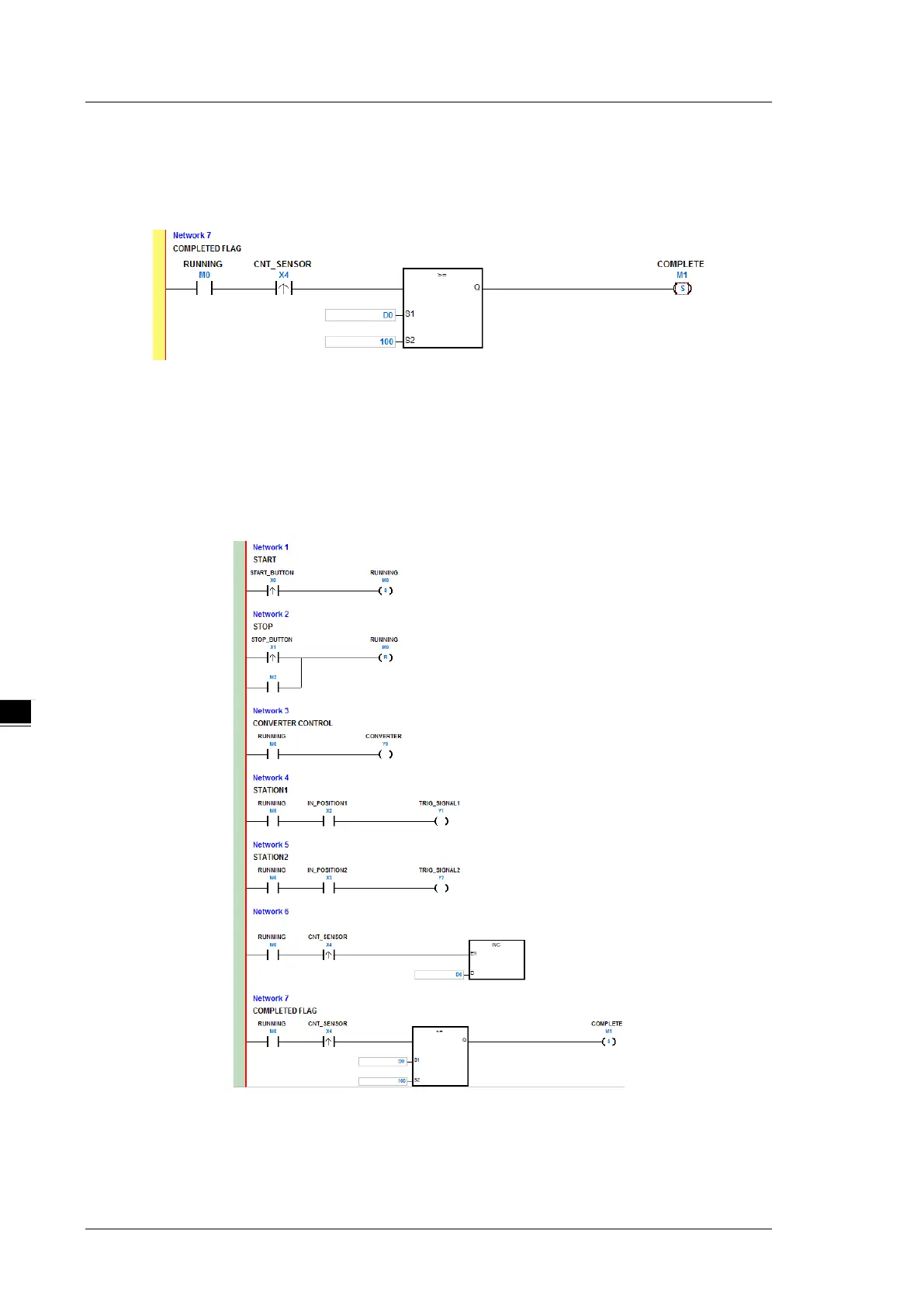

Details program creation, including adding ladder diagrams, basic editing, and instructions.

Covers creating connections, downloading programs, and performing connection and monitoring tests.

Introduces MicroSD cards supported by DVP-ES3 Series and their specifications.

Guides on backing up projects, including program code, parameters, and hardware configuration.

Explains how to restore projects from backup files to the CPU module or PC.

Introduces HWCONFIG for setting CPU/module parameters, downloading, and diagnostics.

Details how to set CPU parameters, including System Information and System Parameter.

Explains setting up data exchange tables for COM ports and Ethernet communication.

Covers installing EtherNet/IP devices, network cable setup, and EIP Builder software.

Lists Ethernet and EtherNet/IP specifications, including communication protocols, speed, and ports.

Provides an overview of error codes and troubleshooting for EtherNet/IP configuration and application errors.

Explains using Rockwell Automation's Studio 5000 for connecting to Delta Ethernet/IP Adapters.

Introduces CANopen networks, benefits, and supported functions like PDO, SDO, and NMT services.

Explains the CANopen protocol, OSI model, object dictionary, and communication objects.

Provides troubleshooting steps for CANopen network node states and error codes.

Describes the CPU module's operation upon power supply, diagnosis, and program execution.

Explains the STOP and RUN modes and their corresponding status and operations.

Provides basic troubleshooting steps, error clearing methods, SOP, and system log access.

Addresses errors indicated by ERROR LED status and provides corresponding solutions.

Presents a table of CPU module LED indicators, error codes, and their descriptions.

Explains using Data Tracer for real-time data collection and curve charting for trend analysis.

Describes using Data Logger for long-term recording of variables and values for trend analysis.

Guides on disabling driver signature enforcement in Windows 8 and 10 for driver installation.

Explains the steps to install the USB driver for the DVP-ES3 Series CPU module on Windows 10.

Lists standard Modbus device addresses for various register types (X, Y, M, SM, S, T, C, HC, D, SR, E).

Lists EMC standards applicable to DVP-ES3 Series systems, covering EMI and EMS.

Provides instructions for installing the PLC in a control box and connecting power/ground for EMC compliance.

Lists essential precautions before performing maintenance and inspection to prevent damage or injury.

Outlines daily inspection steps for the PLC system, including appearance, installation, and connection checks.

Describes periodic maintenance based on operating environment and inspection items like ambient conditions and supply voltage.