October 2019

Installation, Operation and Maintenance Manual

MAN-02-04-97-0713-EN Rev. 1

16

Installation

Section 3: Installation

WARNING

Never lift the valve/actuator assembly without securing slings to both the valve and

the actuator. Never use the handwheel to lift the actuator.

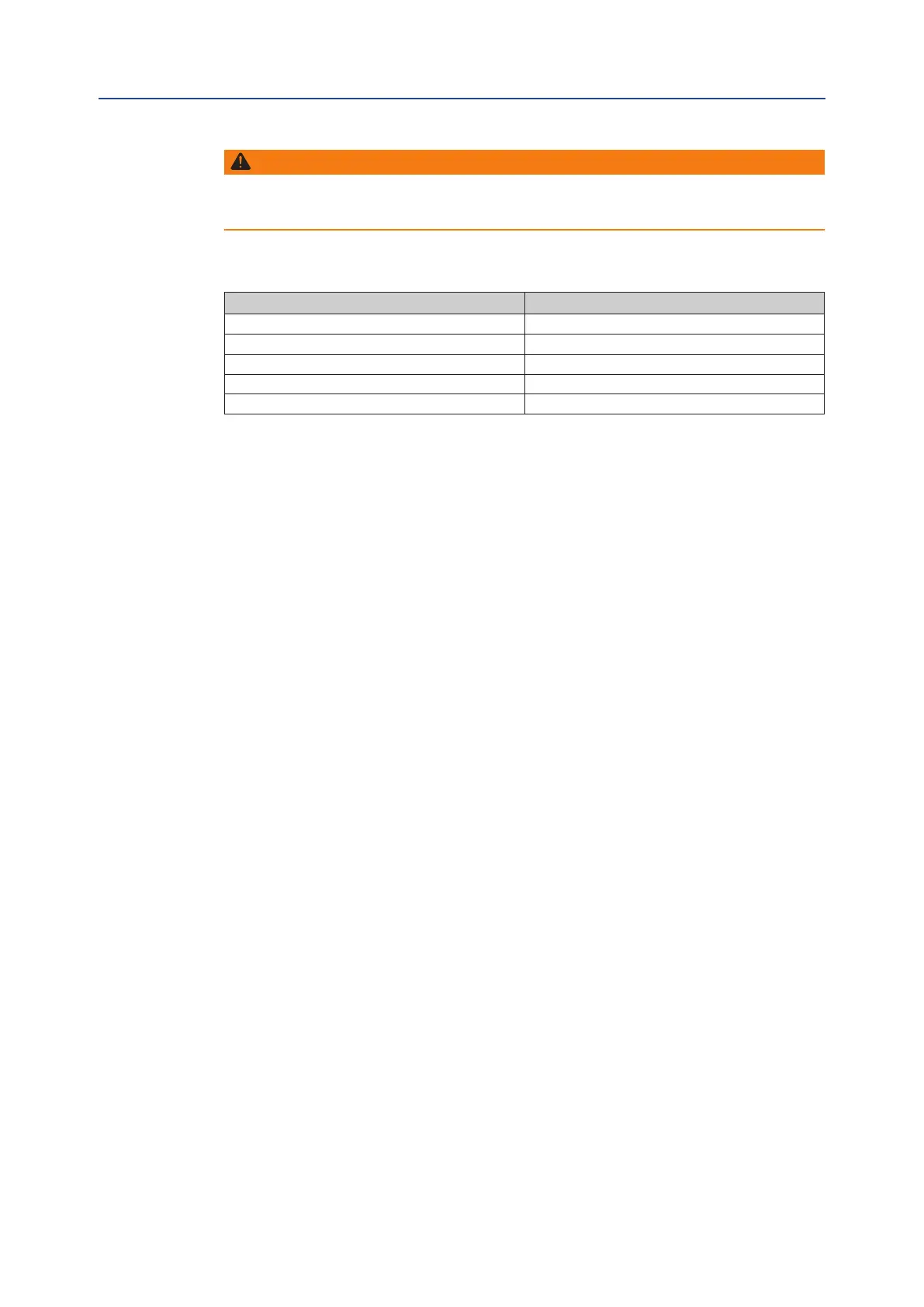

Table 5.

Model Max. weight, kg (lb)

010 32 (70.6)

020 38 (83.8)

030 46 (101.4)

040 56 (123.5)

050 73 (160.9)

3.4 Mounting the Actuator onto the Valve

Lubricate the valve stem.

Thoroughly clean the coupling surfaces of the valve and actuator anges, and degrease

them carefully since torque is transmitted by friction.

Lift the actuator with slings suitable for its weight.

The actuator will operate properly in any position. When mounted upside-down, a 5 mm

diameter hole should be drilled in the end of the stem cover to avoid build-up of service

uid or rainwater.

3.4.1 Coupling Type “A”

Place the actuator vertically on the stem, screw the threaded bushing of the coupling block

on the valve stem, and then rotate (normally counterclockwise) until the coupling block

and ange surfaces of the valve are securely in contact.

For safety purposes, rotate the handwheel in the opening direction for about two turns in

order to lift the valve gate from its seat to avoid imparting (during bolt xing) excessive

axial thrust on the internal parts of the valve and the actuator.

Depending on the conditions of assembly, it could be easier to separate the thrust block

from the actuator and mount it onto the valve yoke.

3.4.2 Coupling Types “B1”, “B2”,”B3” and “B4”

Check the dimensions of the valve mounting details, and pay particular attention to the

protrusions of the valve stem in order to avoid any axial thrust on the internal parts of the

actuator or the valve when the screws are tightened.

Manually engage the actuator using the handwheel and place the actuator vertically on

the valve stem. Perform the coupling operations (with the aid of manual operation if

necessary); make sure no mating parts are forced.

Loading...

Loading...