3-20

FUEL SYSTEM

3-20

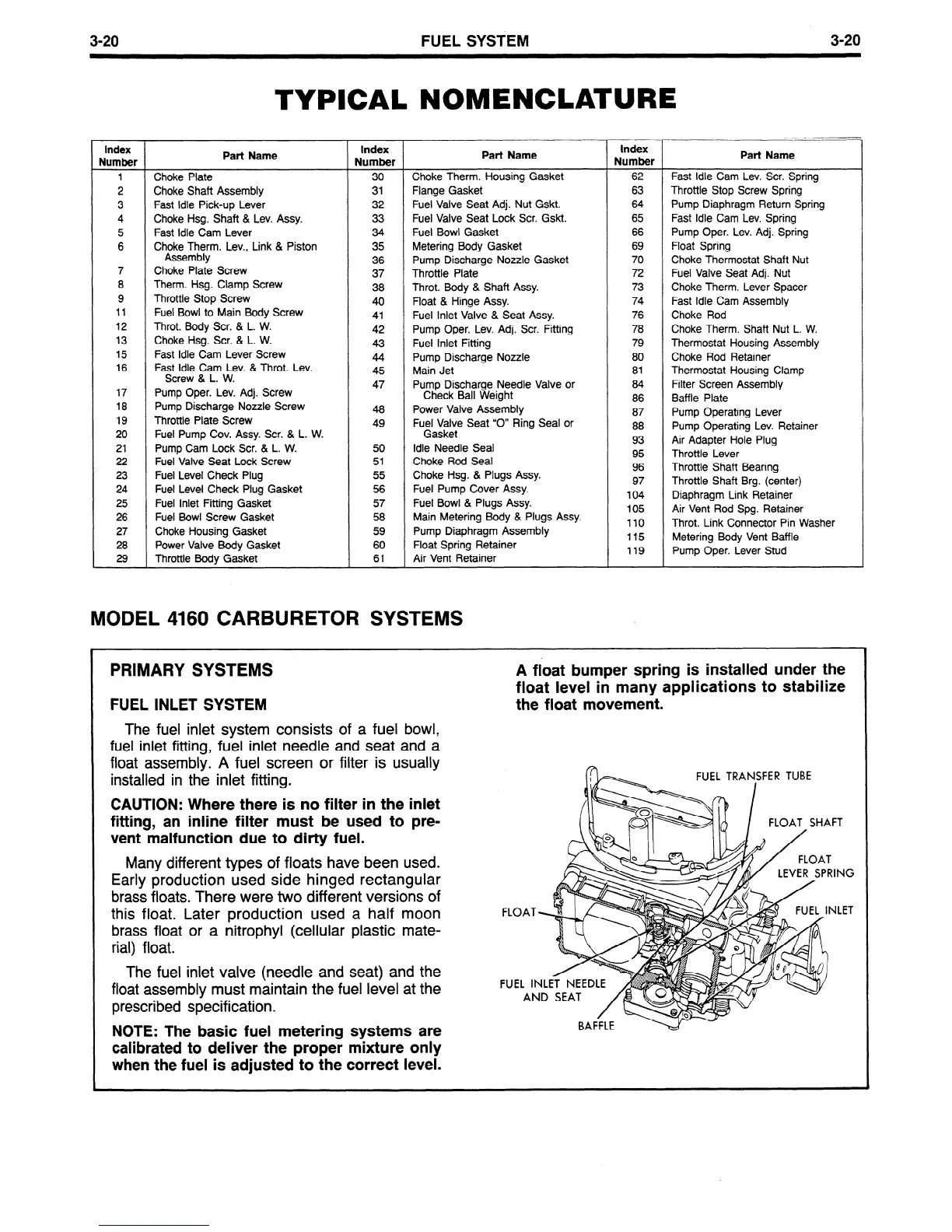

Index

Number

1

2

3

4

5

6

Part Name

Choke Plate

Choke Shaft Assembly

Fast idle Pick-up Lever

Choke Hsg. Shaft & Lev. Assy.

Fast Idle Cam Lever

Choke Therm. Lev., Link & Piston

Assembly

7

Choke Plate Screw

8 Therm. Hsg. Clamp Screw

9 Throttle Stop Screw

11

Fuel

Bowl to Main Body Screw

12 Throt. Body Ser. & L. W.

13

Choke Hsg. Ser. & L. W.

15

Fast Idle Cam Lever Screw

16 Fast idle Cam Lev. & Throt. Lev.

Screw & L. W.

17

Pump Oper. Lev. Adj. Screw

18 Pump Discharge Nozzle Screw

19

Throttle Plate Screw

20

Fuel Pump Cov. Assy. Ser. & L. W.

21 Pump Cam Lock Ser. & L. W.

22 Fuel Valve Seat Lock Screw

23

Fuel Level Check Plug

24 Fuel Level Check Plug Gasket

25

Fuel Inlet Fitting Gasket

26 Fuel Bowl Screw Gasket

27

Choke Housing Gasket

28 Power Valve Body Gasket

29

Throttle Body Gasket

TYPICAL NOMENCLATURE

Index

Number

30

31

32

33

34

35

36

37

38

40

41

42

43

44

45

47

48

49

50

51

55

56

57

58

59

60

61

Part Name

Choke Therm. Housing Gasket

Flange Gasket

Fuel Valve Seat Adj. Nut Gskt.

Fuel

Valve Seat Lock Ser. Gskt.

Fuel Bowl Gasket

Metering Body Gasket

Pump Discharge Nozzle Gasket

Throttle Plate

Throt. Body & Shaft Assy.

Float & Hinge Assy.

Fuel Inlet Valve & Seat Assy.

Pump Oper. Lev. Adj. Ser. Fitting

Fuel Inlet Fitting

Pump Discharge Nozzle

Main Jet

Pump Discharge Needle Valve or

Check Ball Weight

Power Valve Assembly

Fu;;zF Seat “0” Ring Seal or

Idle Needle Seal

Choke Rod Seal

Choke Hsg. & Plugs Assy.

Fuel Pump Cover Assy.

Fuel Bowl & Plugs Assy.

Main Metering Body & Plugs Assy.

Pump Diaphragm Assembly

Float Spring Retainer

Air Vent Retainer

MODEL 4160 CARBURETOR SYSTEMS

Index

Number

62

63

64

65

66

69

70

72

73

74

76

78

79

80

81

84

86

87

88

93

95

96

97

104

105

110

115

119

Part Name

Fast Idle Cam Lev. Ser. Spring

Throttle Stop Screw Spring

Pump Diaphragm Return Spring

Fast Idle Cam Lev. Spring

Pump Oper. Lev. Adj. Spring

Float Spring

Choke Thermostat Shaft Nut

Fuel Valve Seat Adj. Nut

Choke Therm. Lever Spacer

Fast Idle Cam Assembly

Choke Rod

Choke Therm. Shaft Nut L. W.

Thermostat Housing Assembly

Choke Rod Retainer

Thermostat Housing Clamp

Filter Screen Assembly

Baffle Plate

Pump Operating Lever

Pump Operating Lev. Retainer

Air Adapter Hole Plug

Throttle Lever

Throttle Shaft Bearing

Throttle Shaft Brg. (center)

Diaphragm Link Retainer

Air Vent Rod Spg. Retainer

Throt. Link Connector Pin Washer

Metering Body Vent Baffle

Pump Oper. Lever

Stud

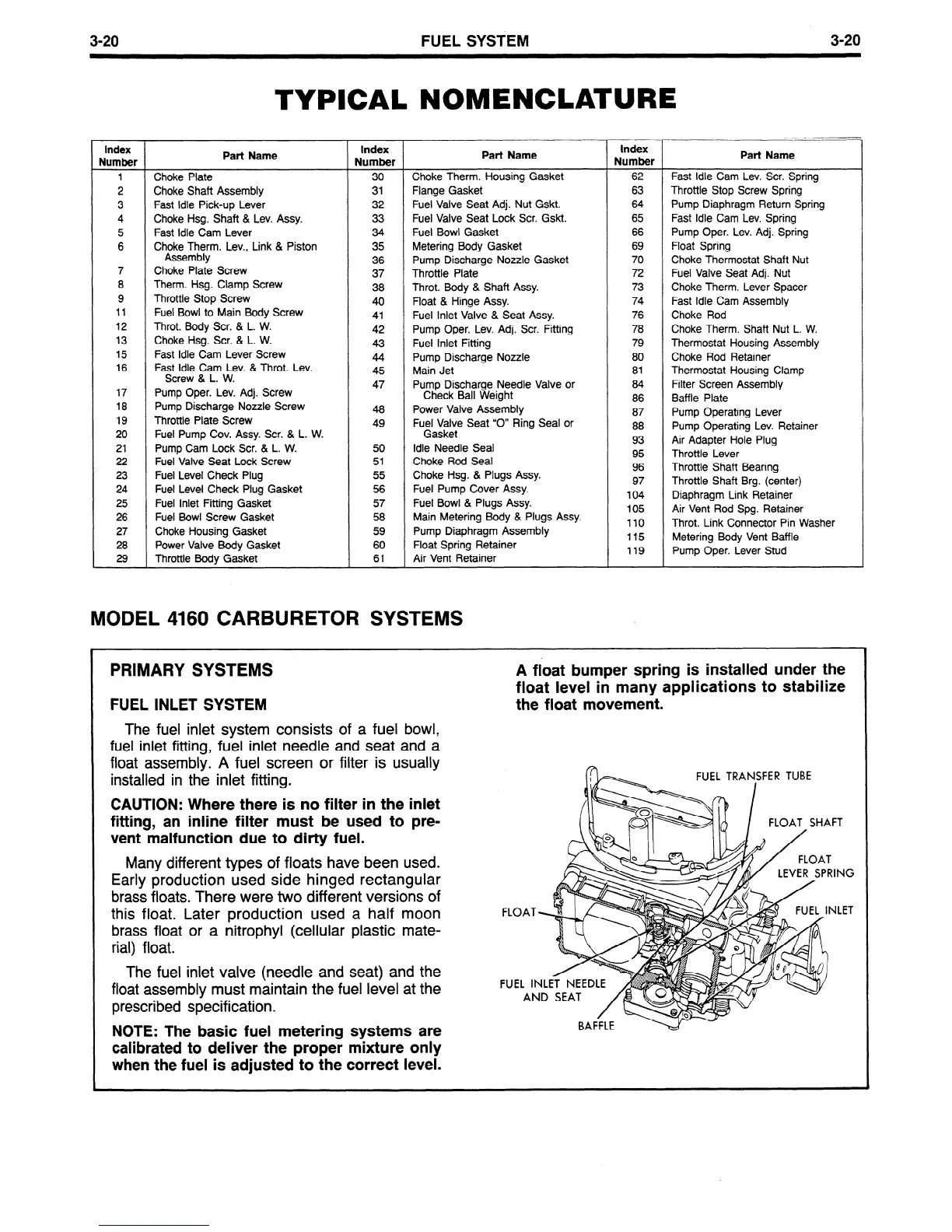

PRIMARY SYSTEMS

A float bumper spring is installed under the

float level in many applications to stabilize

FUEL INLET SYSTEM

The fuel inlet system consists of a fuel bowl,

the float movement.

fuel inlet fitting, fuel inlet needle and seat and a

float assembly. A fuel screen or filter is usually

installed in the inlet fitting.

CAUTION: Where there is no filter in the inlet

fitting, an inline filter must be used to pre-

vent malfunction due to dirty fuel.

Many different types of floats have been used.

Early production used side hinged rectangular

brass floats. There were two different versions of

this float. Later production used a half moon

brass float or a nitrophyl (cellular plastic mate-

rial) float.

The fuel inlet valve (needle and seat) and the

float assembly must maintain the fuel level at the

prescribed specification.

NOTE: The basic fuel metering systems are

calibrated to deliver the proper mixture only

when the fuel is adjusted to the correct level.

Loading...

Loading...