l-17 BASIC ENGINE

I-17

CLEANING AND INSPECTION (Continued)

CONNECTING RODS

Cleaning

Remove the bearings from the rod and cap.

Identify the bearings if they are to be used

again. Clean the connecting rod in solvent, in-

cluding the rod bore and the back of the inserts.

Do not use a caustic cleaning solution.

Blow

out all passages with compressed air.

Inspection

The connecting rods and related parts should

be carefully inspected and checked for confor-

mance to specifications. Various forms of engine

wear caused by these parts can be readily

identified.

A shiny surface on either pin boss side of the

piston usually indicates that a connecting rod is

bent.

Abnormal connecting rod bearing wear can be

caused by either a bent connecting rod, worn or

damaged crankpin, or a tapered connecting rod

bore.

Twisted connecting rods will not create an

easily identifiable wear pattern, but badly twisted

rods will disturb the action of the entire piston,

rings, and connecting rod assembly and may be

the cause of excessive oil consumption.

Inspect the connecting rods for signs of frac-

tures and the bearing bores for out-of-round and

taper. If the bore exceeds the recommended lim-

its and/or if the connecting rod is fractured, it

should be replaced. Check the ID of the con-

necting rod piston pin bore. If the pin bore in the

connecting rod is larger than specifications, in-

stall a

0.002

inch oversize piston pin. First, prefit

the oversize piston pin to the piston pin bore by

reaming or honing the piston. Then, assemble

the piston, piston pin and connecting rod follow-

ing the procedures for assembly.

It is not nec-

essary to ream or hone the pin bore in the

connecting rod. Replace damaged connect-

ing rod nuts and bolts. Check the connecting

rods for bend or twist on a suitable align-

ment fixture. Follow the instructions of the

fixture manufacturer. If the bend and/or twist

exceeds specifications, the connecting rod

must be straightened or replaced.

PISTONS, PINS AND RINGS

Cleaning

Remove deposits from the piston surfaces.

Clean gum or varnish from the piston skirt,

piston pins and rings with solvent.

Do not use a

caustic cleaning solution or a wire brush to

clean pistons.

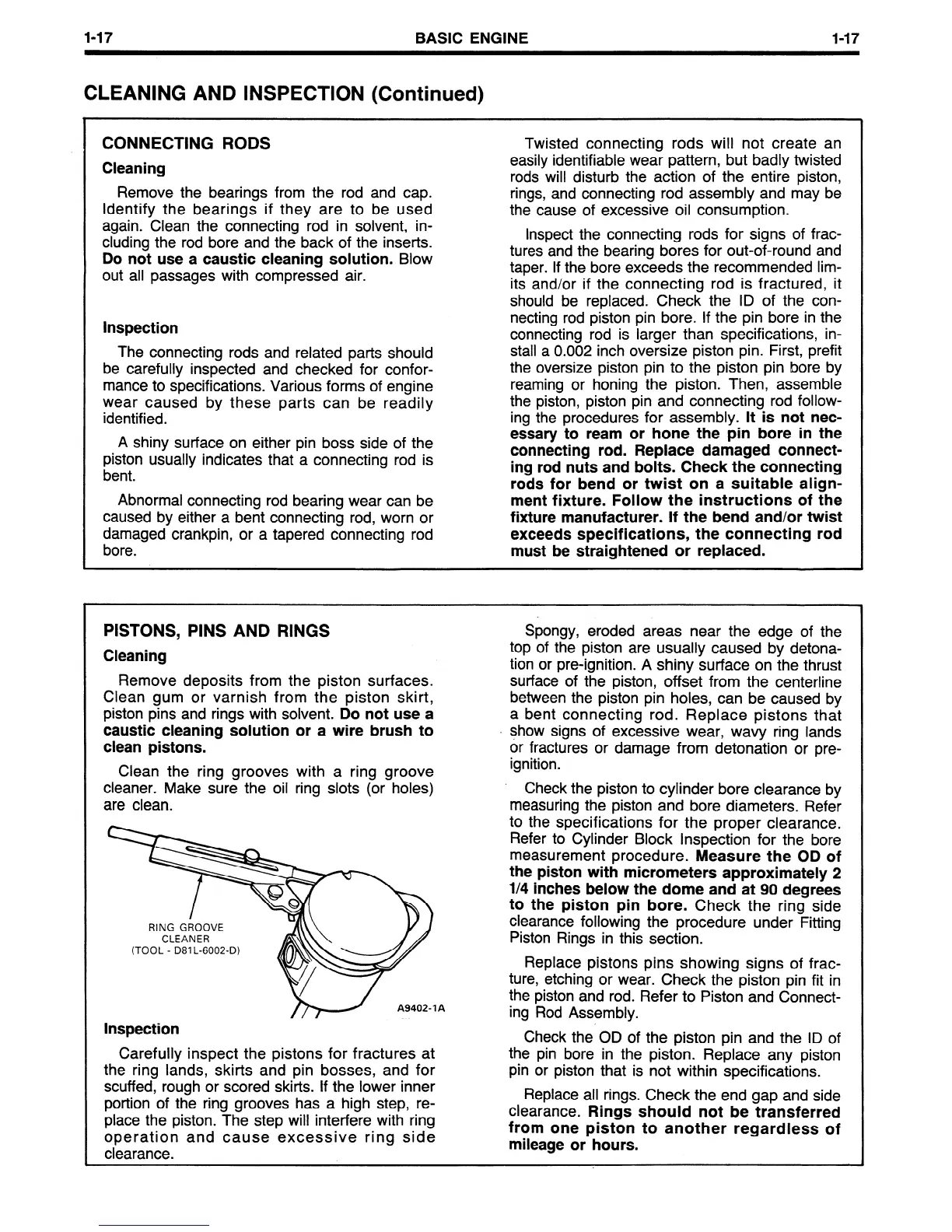

Clean the ring grooves with a ring groove

cleaner. Make sure the oil ring slots (or holes)

are clean.

RING GROOVE

CLEANER

(TOOL - D81 L-6002-D)

A9402-1 A

Inspection

Carefully inspect the pistons for fractures at

the ring lands, skirts and pin bosses, and for

scuffed, rough or scored skirts. If the lower inner

portion of the ring grooves has a high step, re-

place the piston. The step will interfere with ring

operation and cause excessive ring side

clearance.

Spongy, eroded areas near the edge of the

top of the piston are usually caused by detona-

tion or pre-ignition. A shiny surface on the thrust

surface of the piston, offset from the centerline

between the piston pin holes, can be caused by

a bent connecting rod. Replace pistons that

show signs of excessive wear, wavy ring lands

or fractures or damage from detonation or pre-

ignition.

Check the piston to cylinder bore clearance by

measuring the piston and bore diameters. Refer

to the specifications for the proper clearance.

Refer to Cylinder Block Inspection for the bore

measurement procedure.

Measure the OD of

the piston with micrometers approximately 2

l/4 inches below the dome and at 90 degrees

to the piston pin bore.

Check the ring side

clearance following the procedure under Fitting

Piston Rings in this section.

Replace pistons pins showing signs of frac-

ture, etching or wear. Check the piston pin fit in

the piston and rod. Refer to Piston and Connect-

ing Rod Assembly.

Check the OD of the piston pin and the ID of

the pin bore in the piston. Replace any piston

pin or piston that is not within specifications.

Replace all rings. Check the end gap and side

clearance.

Rings should not be transferred

from one piston to another regardless of

mileage or hours.

Loading...

Loading...