3-l 1

FUEL SYSTEM

341

MODEL 2300 2-V CARBURETOR (Continued)

FUEL LEVEL ADJUSTMENT - WET

The fuel pump pressure and volume must be

to specifications prior to performing the following

adjustments.

1. Operate the engine to normalize engine

temperatures and place the engine on a flat

surface, as near level as possible. Stop the

engine and remove the air cleaner, if it was

not previously removed.

2. Check the fuel level in each fuel bowl sepa-

rately.

Place a suitable container below

the fuel level sight plug in the fuel bowl

to collect any spillover of fuel. Carefully

remove the fuel level sight plug and

gasket.

3. If the fuel level is satisfactory, install the

sight plug.

4. If the fuel level is too high, drain the fuel

bowl and refill it. To drain the fuel bowl,

loosen one lower retaining bolt from the fuel

bowl and drain the fuel into a suitable con-

tainer. Check the fuel level again before al-

tering the float setting.

This will eliminate

the possibility of foreign material causing

a temporary flooding condition. Install

the bolt and the fuel level sight plug, and

start the engine to fill the fuel bowl. After

the fuel level has stabilized, stop the en-

gine and check the fuel level.

If the fuel level is still too high, it should

first be lowered below specifications and

then raised until it is just at the lower edge of

the sight plug opening. If the fuel level is too

low, it is only necessary to raise it to the

specified level. Follow the procedure under

To Lower Fuel Level or To Raise Fuel Level,

whichever is applicable.

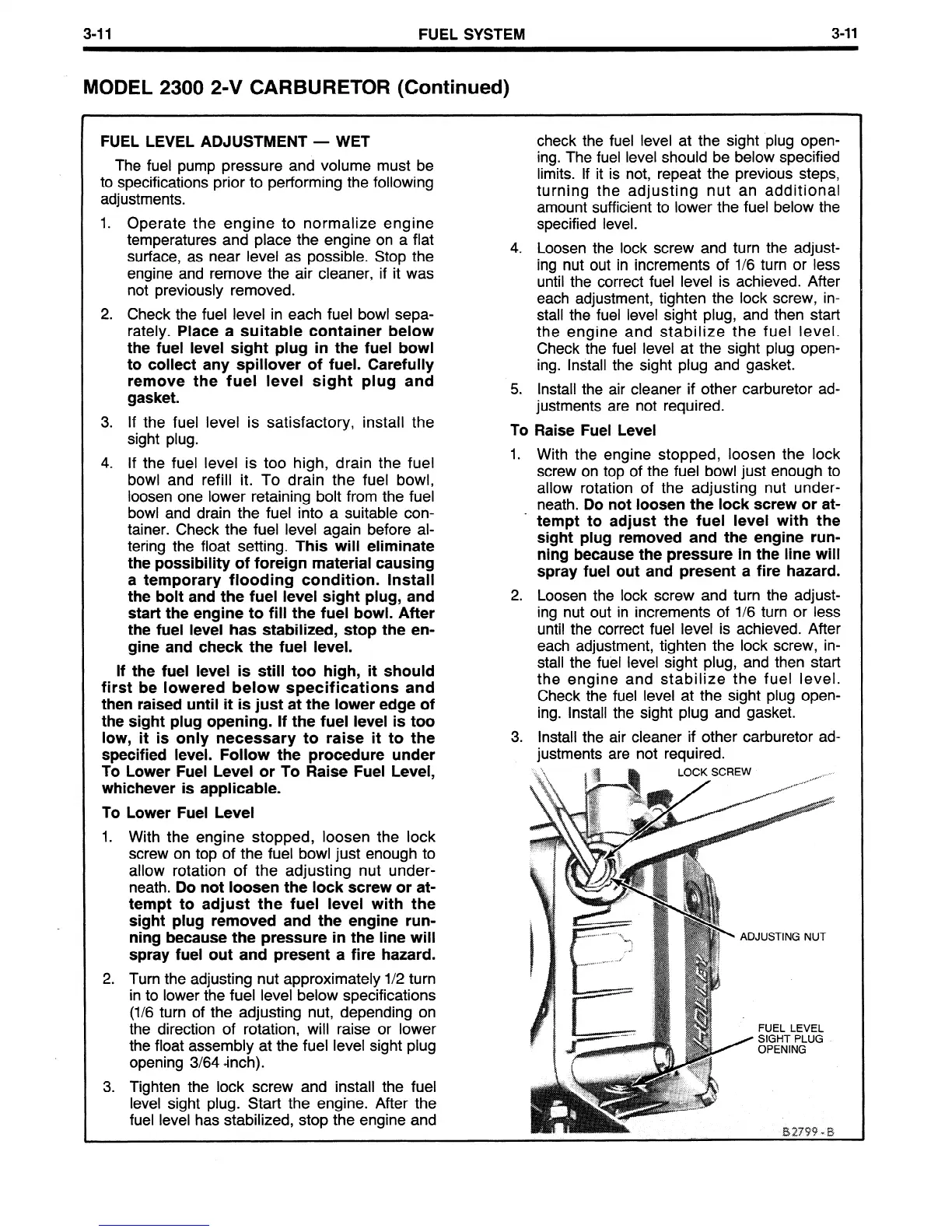

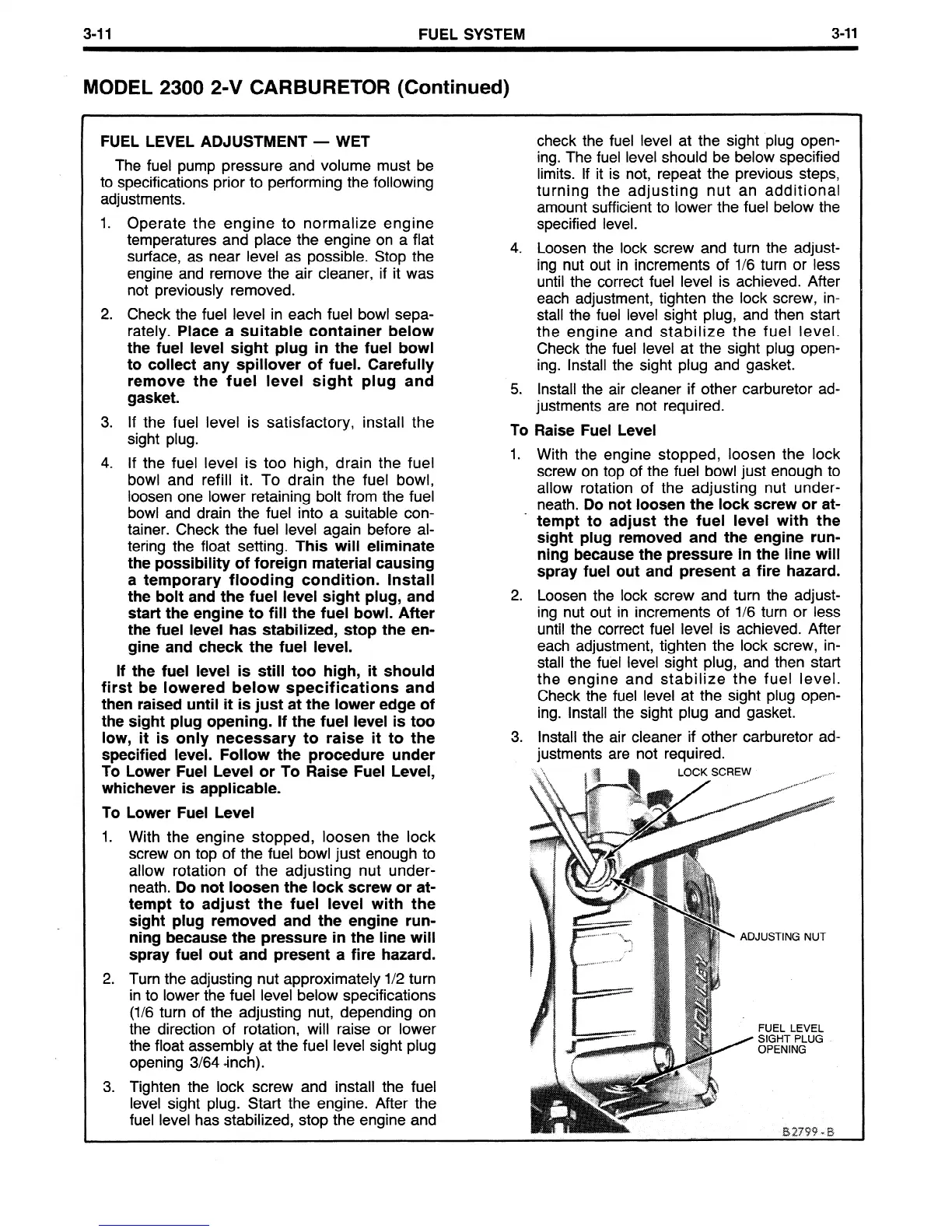

To Lower Fuel Level

1. With the engine stopped, loosen the lock

screw on top of the fuel bowl just enough to

allow rotation of the adjusting nut under-

neath.

Do not loosen the lock screw or at-

tempt to adjust the fuel level with the

sight plug removed and the engine run-

ning because the pressure in the line will

spray fuel out and present a fire hazard.

2. Turn the adjusting nut approximately l/2 turn

in to lower the fuel level below specifications

(l/6 turn of the adjusting nut, depending on

the direction of rotation, will raise or lower

the float assembly at the fuel level sight plug

opening 3/64 inch).

3. Tighten the lock screw and install the fuel

level sight plug. Start the engine. After the

fuel level has stabilized, stop the engine and

4 .

check the fuel level at the sight plug open-

ing. The fuel level should be below specified

limits. If it is not, repeat the previous steps,

turning the adjusting nut an additional

amount sufficient to lower the fuel below the

specified level.

Loosen the lock screw and turn the adjust-

ing nut out in increments of l/6 turn or less

until the correct fuel level is achieved. After

each adjustment, tighten the lock screw, in-

stall the fuel level sight plug, and then start

the engine and stabilize the fuel level.

Check the fuel level at the sight plug open-

ing. Install the sight plug and gasket.

5. Install the air cleaner if other carburetor ad-

justments are not required.

To Raise Fuel Level

1. With the engine stopped, loosen the lock

screw on top of the fuel bowl just enough to

allow rotation of the adjusting nut under-

neath.

Do not loosen the lock screw or at-

tempt to adjust the fuel level with the

sight plug removed and the engine run-

ning because the pressure in the line will

spray fuel out and present a fire hazard.

2. Loosen the lock screw and turn the adjust-

ing nut out in increments of l/6 turn or less

until the correct fuel level is achieved. After

each adjustment, tighten the lock screw, in-

stall the fuel level sight plug, and then start

the engine and stabilize the fuel level.

Check the fuel level at the sight plug open-

ing. Install the sight plug and gasket.

3. Install the air cleaner if other carburetor ad-

justments are not required.

Loading...

Loading...