l-10

BASIC ENGINE

l-10

DIAGNOSIS AND TESTING

(Continued)

POSITIVE CLOSED-TYPE VENTILATION

SYSTEM

A malfunctioning closed crankcase ventilation

system may be indicated by loping or rough en-

gine idle. Do not attempt to compensate for this

idle condition by disconnecting the crankcase

ventilation system and making carburetor adjust-

ments.

The removal of the crankcase ventila-

tion system from the engine will adversely

affect the fuel economy and engine ventila-

tion with resultant shortening of engine life.

To determine whether the loping or rough idle

condition is caused by a malfunctioning crank-

case ventilation system, perform the following

test.

CRANKCASE VENTILATION REGULATOR

VALVE TEST

Install d known good regulator valve (PCV) in

the crankcase ventilation system.

Start the engine and compare the engine idle

condition to the prior idle condition.

If the idle condition is found to be satisfactory,

use the new regulator valve and clean the

hoses, fittings, etc.

If the loping or rough idle condition remains

when the good regulator valve is installed, the

crankcase ventilation regulator valve is not at

fault. Check the crankcase ventilation system for

restriction at the intake manifold or carburetor

spacer. If the system is not restricted, further en-

gine component diagnosis will have to be con-

ducted to find the malfunction.

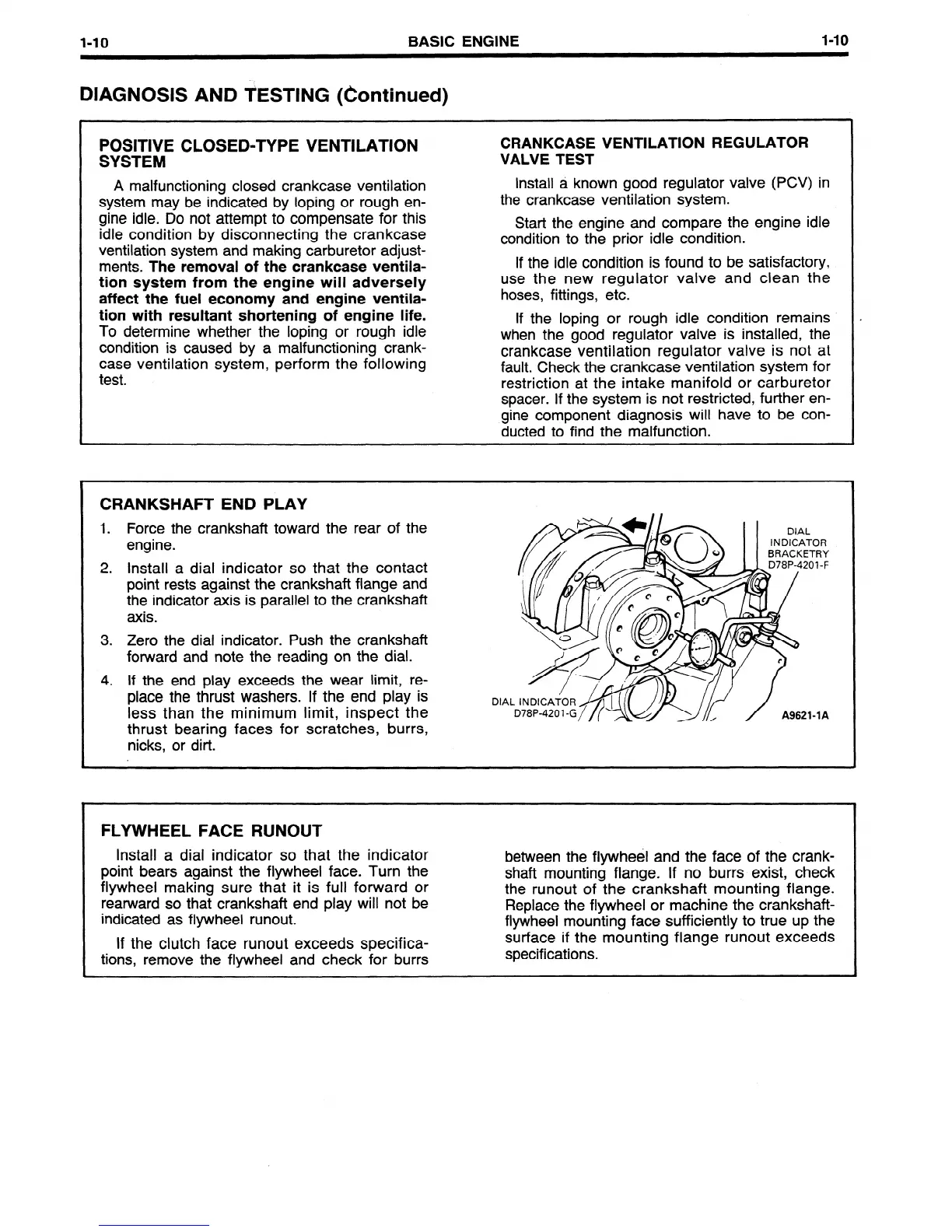

CRANKSHAFT END PLAY

1. Force the crankshaft toward the rear of the

engine.

2. Install a dial indicator so that the contact

point rests against the crankshaft flange and

the indicator axis is parallel to the crankshaft

axis.

3. Zero the dial indicator. Push the crankshaft

forward and note the reading on the dial.

4. If the end play exceeds the wear limit, re-

place the thrust washers. If the end play is

less than the minimum limit, inspect the

thrust bearing faces for scratches, burrs,

nicks, or dirt.

DIA

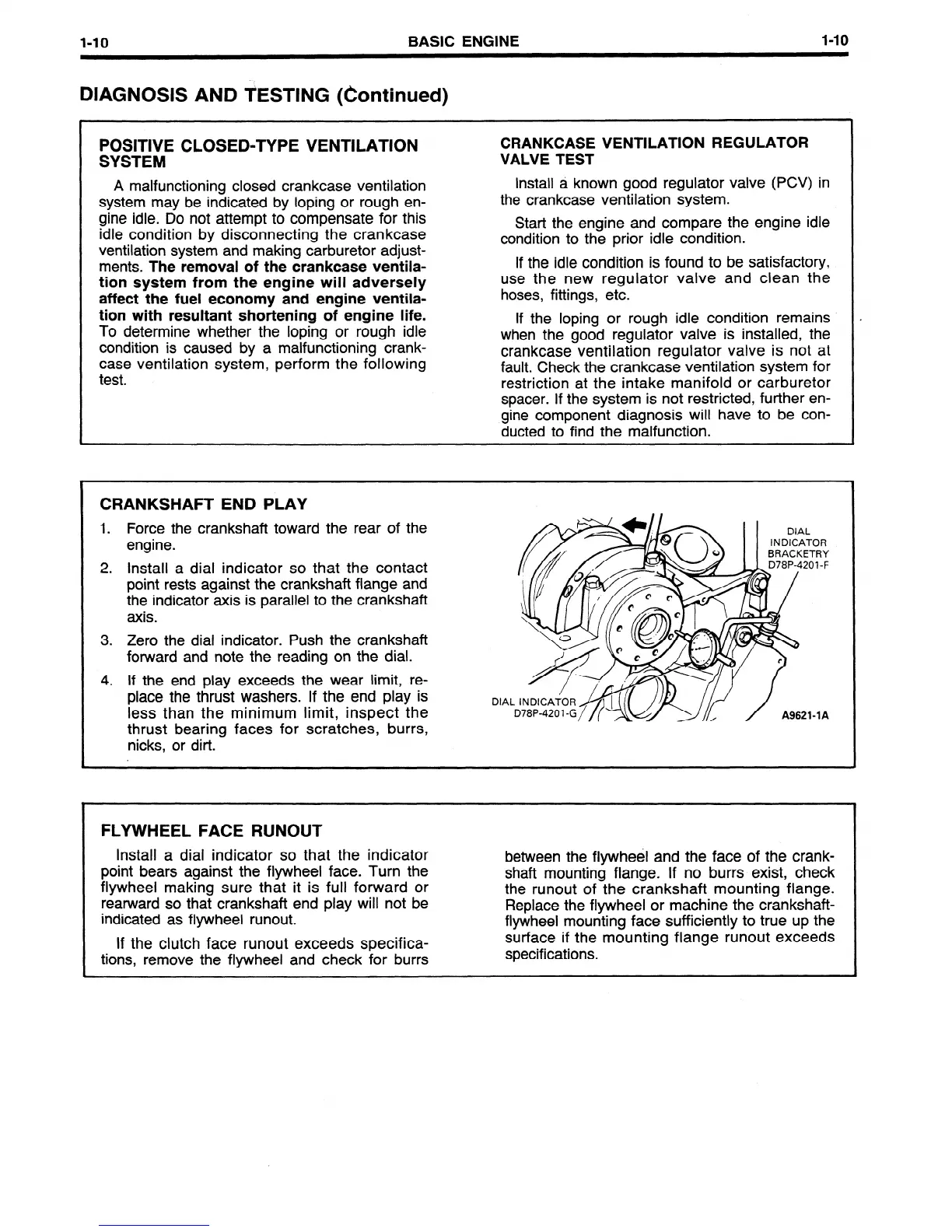

FLYWHEEL FACE RUNOUT

Install a dial indicator so that the indicator

point bears against the flywheel face. Turn the

flywheel making sure that it is full forward or

rearward so that crankshaft end play will not be

indicated as flywheel runout.

If the clutch face runout exceeds specifica-

tions, remove the flywheel and check for burrs

between the flywheel and the face of the crank-

shaft mounting flange. If no burrs exist, check

the runout of the crankshaft mounting flange.

Replace the flywheel or machine the crankshaft-

flywheel mounting face sufficiently to true up the

surface if the mounting flange runout exceeds

specifications.

Loading...

Loading...