5-08

STARTING SYSTEM

5-08

DISASSEMBLY AND ASSEMBLY (Continued)

ASSEMBLY

1.

Position the three coils and pole pieces, then

install the attaching screws. As the pole shoe

screws are tightened, strike the frame several

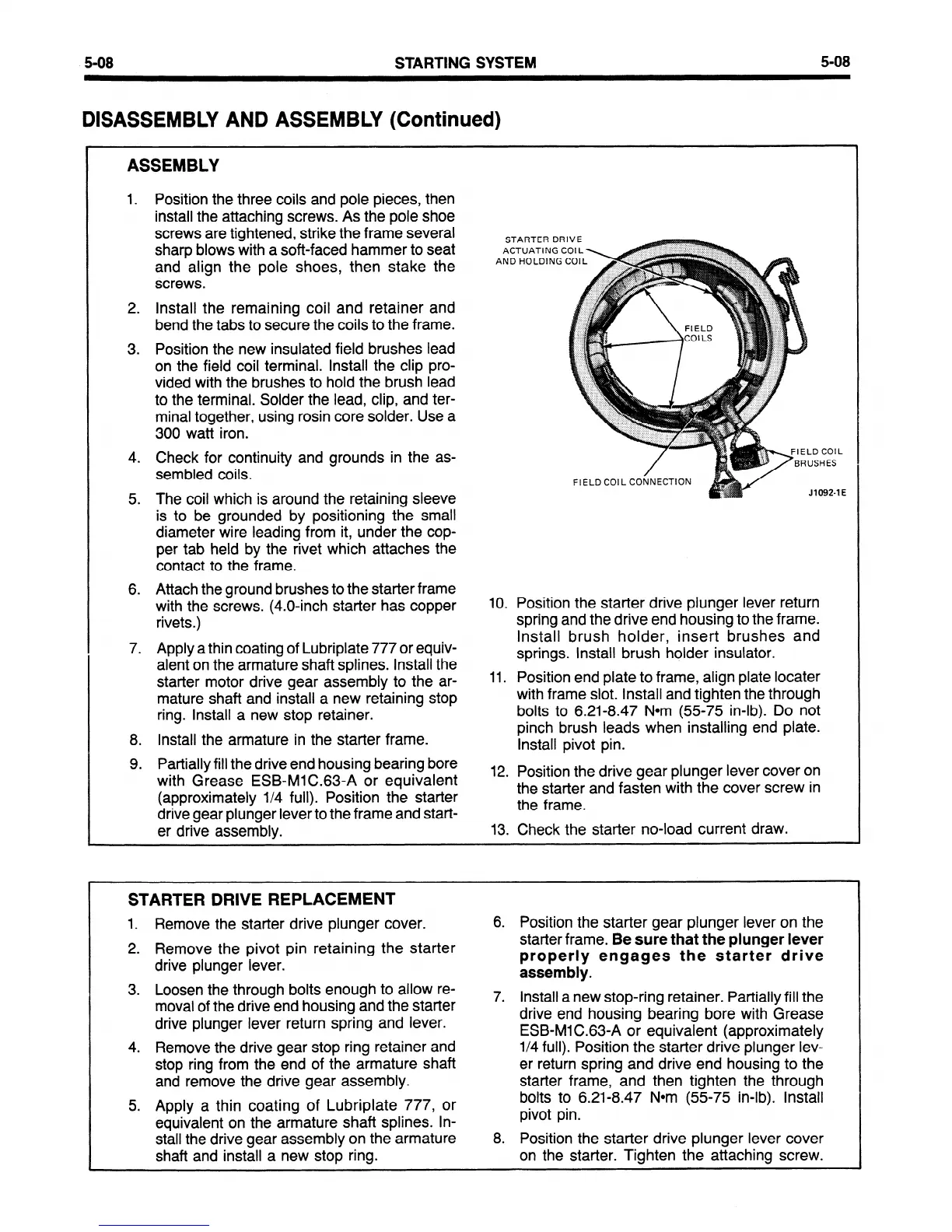

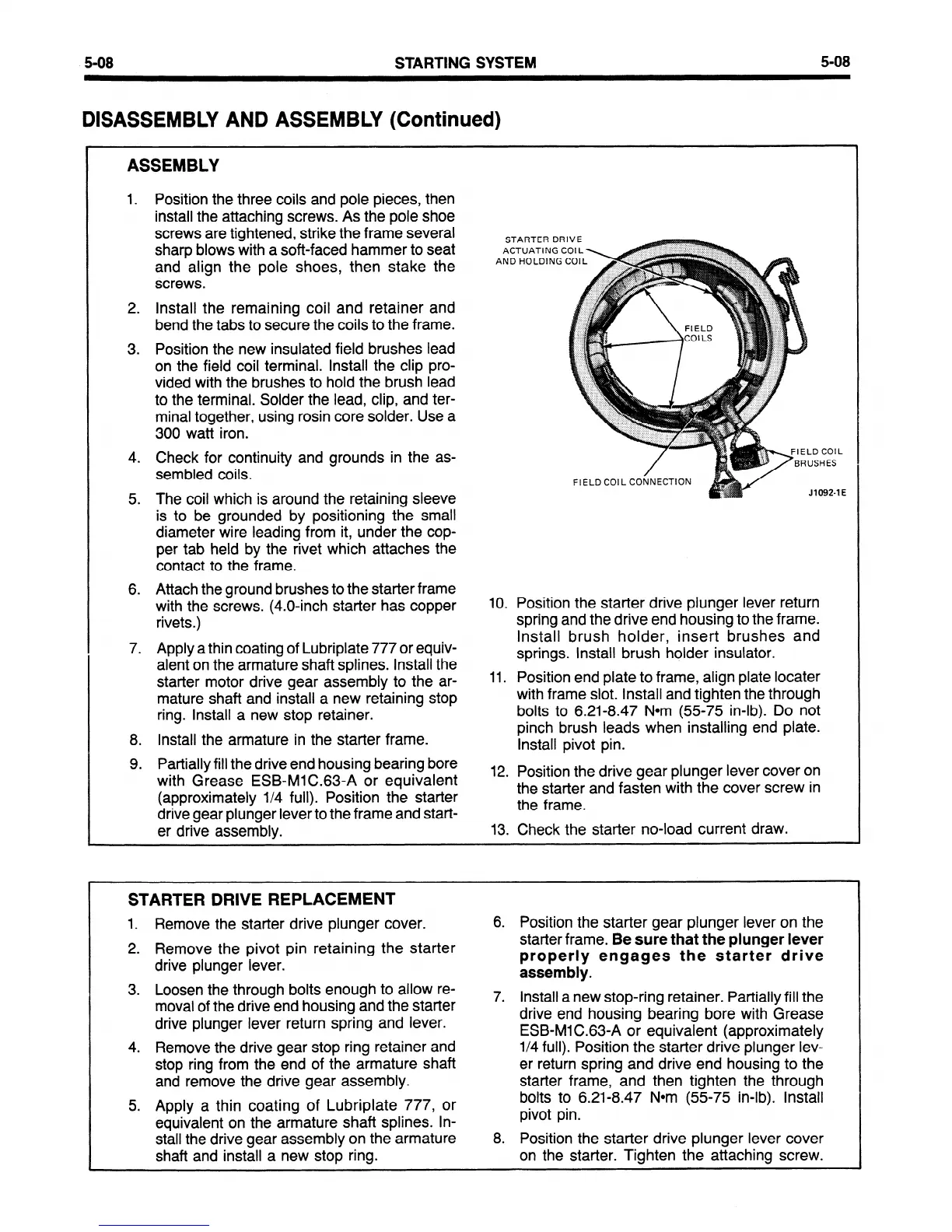

STARTER DRIV

sharp blows with a soft-faced hammer to seat

ACTUATING COI

and align the pole shoes, then stake the

AND HOLDING CO

screws.

2. Install the remaining coil and retainer and

bend the tabs to secure the coils to the frame.

3. Position the new insulated field brushes lead

on the field coil terminal. Install the clip pro-

vided with the brushes to hold the brush lead

to the terminal. Solder the lead, clip, and ter-

minal together, using rosin core solder. Use a

300

watt iron.

4.

Check for continuity and grounds in the as-

sembled coils.

FIELD COIL CONNECTION

5.

The coil which is around the retaining sleeve

is to be grounded by positioning the small

diameter wire leading from it, under the cop-

per tab held by the rivet which attaches the

contact to the frame.

6. Attach the ground brushes to the starter frame

with the screws. (4.0.inch starter has copper

10. Position the starter drive plunger lever return

rivets .)

spring and the drive end housing to the frame.

7. Apply a thin coating of Lubriplate 777 or equiv-

Install brush holder, insert brushes and

alent on the armature shaft splines. Install the

springs. Install brush holder insulator.

starter motor drive gear assembly to the ar-

11. Position end plate to frame, align plate locater

mature shaft and install a new retaining stop

with frame slot. Install and tighten the through

ring. Install a new stop retainer.

bolts to 6.21-8.47 Nom (55-75 in-lb). Do not

8. Install the armature in the starter frame.

pinch brush leads when installing end plate.

Install pivot pin.

9. Partially fill the drive end housing bearing bore

with Grease ESB-MIC.63-A or equivalent

12. Position the drive gear plunger lever cover on

(approximately l/4 full). Position the starter

the starter and fasten with the cover screw in

drive gear plunger lever to the frame and start-

the frame.

er drive assembly.

13. Check the starter no-load current draw.

STARTER DRIVE REPLACEMENT

1. Remove the starter drive plunger cover.

2. Remove the pivot pin retaining the starter

drive plunger lever.

3. Loosen the through bolts enough to allow re-

moval of the drive end housing and the starter

drive plunger lever return spring and lever.

4. Remove the drive gear stop ring retainer and

stop ring from the end of the armature shaft

and remove the drive gear assembly.

5. Apply a thin coating of Lubriplate 777, or

equivalent on the armature shaft splines. In-

stall the drive gear assembly on the armature

shaft and install a new stop ring.

6. Position the starter gear plunger lever on the

starter frame.

Be sure that the plunger lever

properly engages the starter drive

assembly.

7. install a new stop-ring retainer. Partially fill the

drive end housing bearing bore with Grease

ESB-Ml C.63-A or equivalent (approximately

l/4 full). Position the starter drive plunger lev-

er return spring and drive end housing to the

starter frame, and then tighten the through

bolts to 6.21-8.47 Nom (55-75 in-lb). Install

pivot pin.

8. Position the starter drive plunger lever cover

on the starter. Tighten the attaching screw.

Loading...

Loading...