l-22

BASIC ENGINE

I-22

OVERHAUL (Continued)

VALVES

Minor pits, grooves, etc., may be removed.

Discard valves that are severely damaged, if the

face runout cannot be corrected by refinishing or

stem clearance exceeds specifications.

Discard

any excessively worn or damaged valve train

parts.

REFACING VALVES

The valve refacing operation should be closely

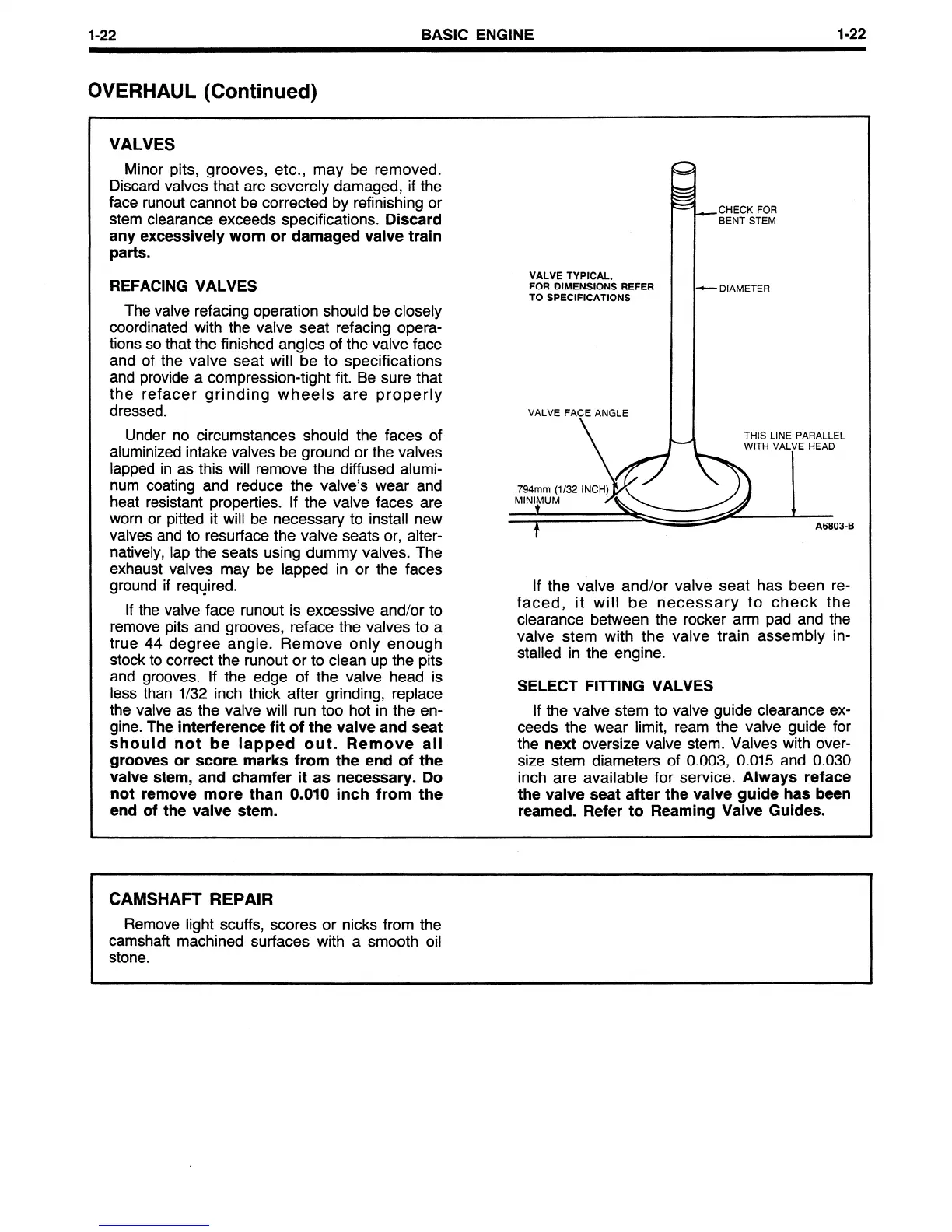

VALVE TYPICAL,

FOR DIMENSIONS REFER

-DIAMETER

TO SPECIFICATIONS

coordinated with the valve seat refacing opera-

tions so that the finished angles of the valve face

and of the valve seat will be to specifications

and provide a compression-tight fit. Be sure that

the refacer grinding wheels are properly

dressed.

Under no circumstances should the faces of

aluminized intake valves be ground or the valves

lapped in as this will remove the diffused alumi-

num coating and reduce the valve’s wear and

heat resistant properties. If the valve faces are

worn or pitted it will be necessary to install new

valves and to resurface the valve seats or, alter-

natively, lap the seats using dummy valves. The

exhaust valves may be lapped in or the faces

ground if required.

If the valveiace runout is excessive and/or to

remove pits and grooves, reface the valves to a

true 44 degree angle. Remove only enough

stock to correct the runout or to clean up the pits

and grooves. If the edge of the valve head is

less than l/32 inch thick after grinding, replace

the valve as the valve will run too hot in the en-

gine.

The interference fit of the valve and seat

should not be lapped out. Remove all

grooves or score marks from the end of the

valve stem, and chamfer it as necessary. Do

not remove more than 0.010 inch from the

end of the valve stem.

VALVE FACE ANGLE

THIS LINE PARALLEL

WITH VALVE HEAD

f

A6803-B

If the valve and/or valve seat has been re-

faced, it will be necessary to check the

clearance between the rocker arm pad and the

valve stem with the valve train assembly in-

stalled in the engine.

SELECT FITTING VALVES

If the valve stem to valve guide clearance ex-

ceeds the wear limit, ream the valve guide for

the

next

oversize valve stem. Valves with over-

size stem diameters of 0.003, 0.015 and 0.030

inch are available for service.

Always reface

the valve seat after the valve guide has been

reamed. Refer to Reaming Valve Guides.

CAMSHAFT REPAIR

Remove light scuffs, scores or nicks from the

camshaft machined surfaces with a smooth oil

stone.

Loading...

Loading...