l-19

BASIC ENGINE

l-19

CLEANING AND INSPECTION (Continued)

CYLINDER BLOCK

Cleaning

After any cylinder bore repair operation, such

as honing or deglazing, clean the bore(s) with

soap or detergent and water. Then, thoroughly

rinse the bore(s) with clean water to remove the

soap or detergent, and wipe the bore(s) dry with

a clean, lint-free cloth. Finally, wipe the bore(s)

with a clean cloth dipped in engine oil. If these

procedures are not followed, rusting of the cylin-

der bore(s) may occur.

If the engine is disassembled, thoroughly

clean the block with solvent. Remove old gasket

material from all machined surfaces. Remove all

pipe plugs that seal oil passages; then clean out

all the passages. Blow out all passages, bolt

holes, etc., with compressed air. Make sure the

threads in the cylinder head bolt holes are clean.

Dirt in the threads may cause binding and result

in a false torque reading. Use a tap to true up

threads and to remove any deposits. Thoroughly

clean the grooves in the crankshaft bearings and

bearing retainers.

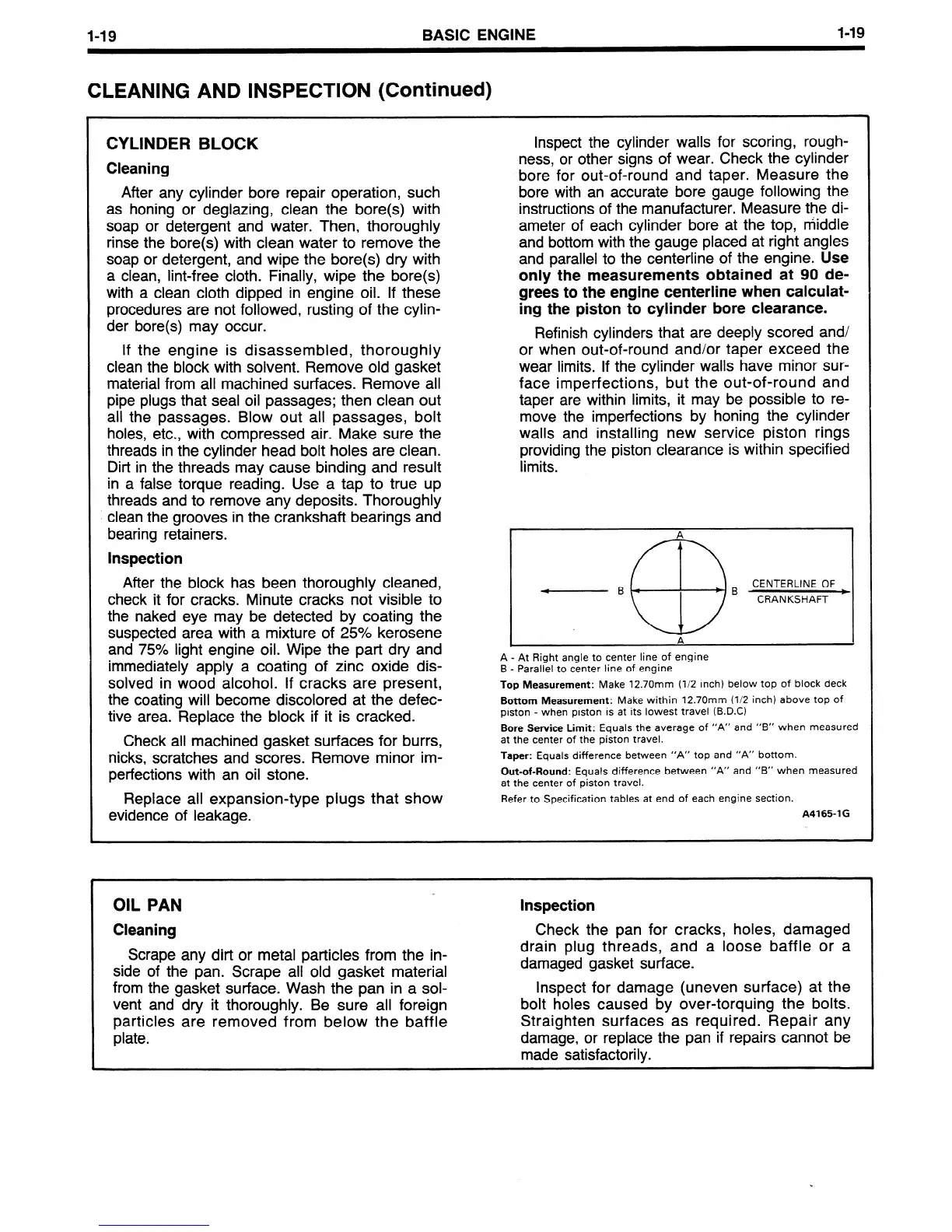

Inspect the cylinder wails for scoring, rough-

ness, or other signs of wear. Check the cylinder

bore for out-of-round and taper. Measure the

bore with an accurate bore gauge following the

instructions of the manufacturer. Measure the di-

ameter of each cylinder bore at the top, middle

and bottom with the gauge placed at right angles

and parallel to the centerline of the engine.

Use

only the measurements obtained at 90 de-

grees to the engine centerline when calculat-

ing the piston to cylinder bore clearance.

Refinish cylinders that are deeply scored and/

or when out-of-round and/or taper exceed the

wear limits. If the cylinder walls have minor sur-

face imperfections, but the out-of-round and

taper are within limits, it may be possible to re-

move the imperfections by honing the cylinder

walls and installing new service piston rings

providing the piston clearance is within specified

limits.

t

A

Inspection

check it for cracks. Minute cracks not visible to

After the block has been thoroughly cleaned,

the naked eye may be detected by coating the

suspected area with a mixture of 25% kerosene

and 75% light engine oil. Wipe the part dry and

immediately apply a coating of zinc oxide dis-

solved in wood alcohol. If cracks are present,

the coating will become discolored at the defec-

tive area. Replace the block if it is cracked.

Check all machined gasket surfaces for burrs,

nicks, scratches and scores. Remove minor im-

perfections with an oil stone.

Replace all expansion-type plugs that show

evidence of leakage.

-B

. fi

B CENTERLINE OF

CRANKSHAFT

l

A

A - At Right angle to center line of engine

B - Parallel to center line of engine

Top Measurement:

Make 12.70mm (l/2 inch) below top of block deck

Bottom Measurement:

Make within 12.70mm (l/2 inch) above top of

piston - when piston is at its lowest travel (B.D.C)

Bore Service Limit:

Equals the average of “A” and “B” when measured

at the center of the piston travel.

Taper:

Equals difference between “A” top and “A” bottom.

Out-of-Round:

Equals difference between “A” and “B” when measured

at the center of piston travel.

Refer to Specification tables at end of each engine section.

A41651G

OIL PAN

Cleaning

Scrape any dirt or metal particles from the in-

side of the pan. Scrape all old gasket material

from the gasket surface. Wash the pan in a sol-

vent and dry it thoroughly. Be sure all foreign

particles are removed from below the baffle

plate.

Inspection

Check the pan for cracks, holes, damaged

drain plug threads, and a loose baffle or a

damaged gasket surface.

Inspect for damage (uneven surface) at the

bolt holes caused by over-torquing the bolts.

Straighten surfaces as required. Repair any

damage, or replace the pan if repairs cannot be

made satisfactorily.

Loading...

Loading...