1-21

BASIC ENGINE

1-21 )

OVERHAUL

CYLINDER HEAD

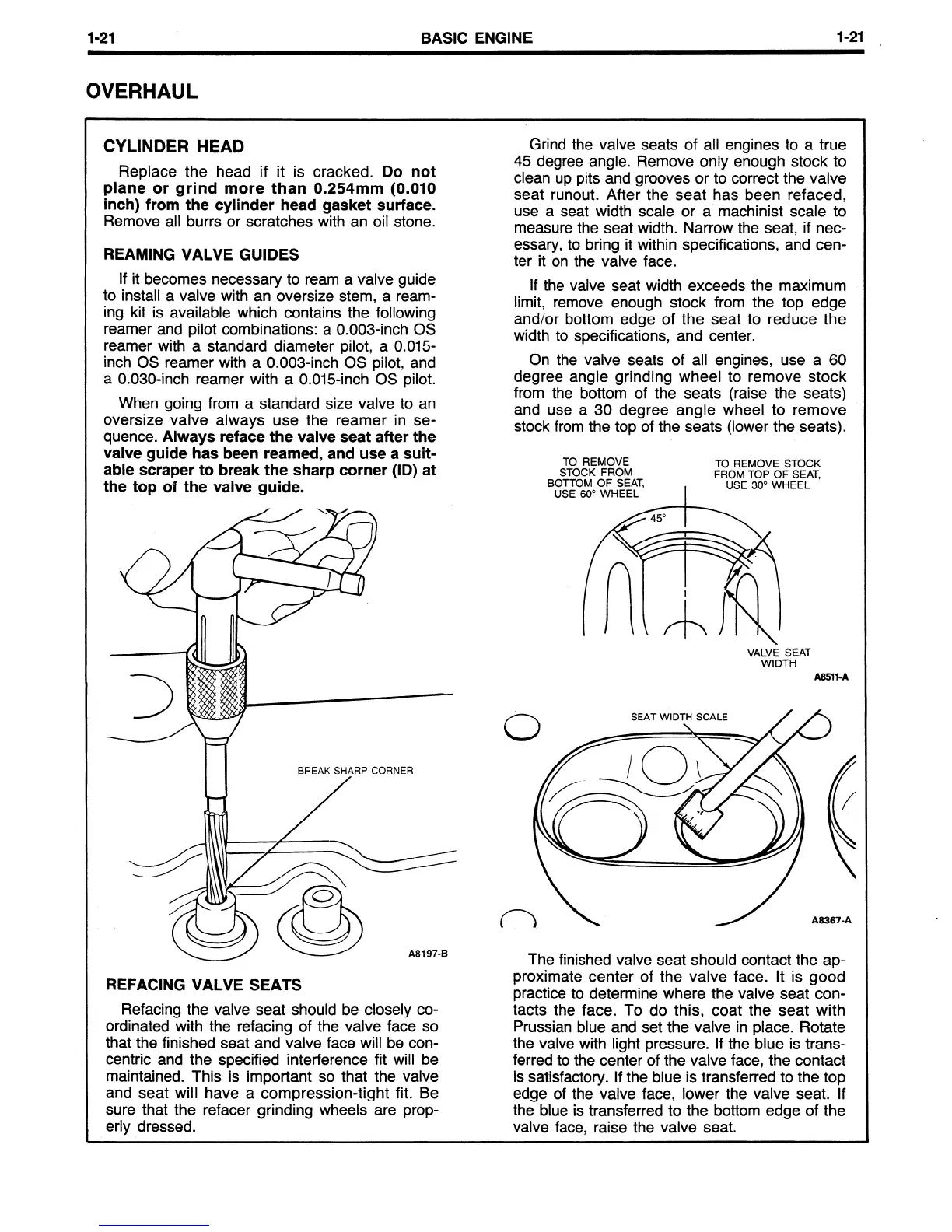

Grind the valve seats of all engines to a true

Replace the head if it is cracked.

Do not

plane or grind more than 0.254mm (0.010

inch) from the cylinder head gasket surface.

Remove all burrs or scratches with an oil stone.

45 degree angle. Remove only enough stock to

clean up pits and grooves or to correct the valve

seat runout. After the seat has been refaced,

use a seat width scale or a’ machinist scale to

measure the seat width. Narrow the seat, if nec-

REAMING VALVE GUIDES

essary, to bring it within specifications, and cen-

ter it on the valve face.

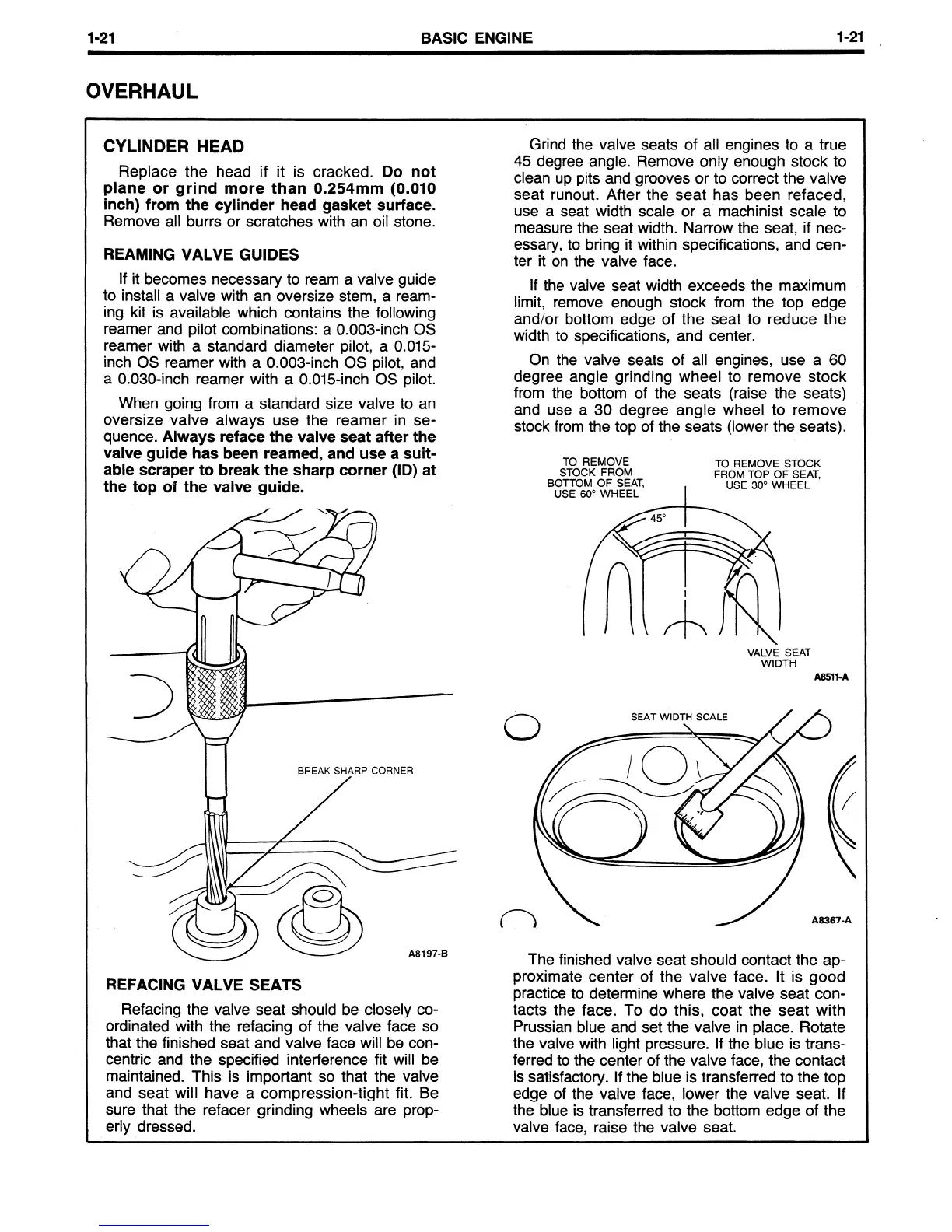

If it becomes necessary to ream a valve guide

to install a valve with an oversize stem, a ream-

ing kit is available which contains the following

reamer and pilot combinations: a 0.003-inch OS

reamer with a standard diameter pilot, a 0.015

inch OS reamer with a 0.003-inch OS pilot, and

a 0.030-inch reamer with a 0.015inch OS pilot.

When going from a standard size valve to an

oversize valve always use the reamer in se-

quence.

Always reface the valve seat after the

valve guide has been reamed, and use a suit-

able scraper to break the sharp corner (ID) at

the top of the valve guide.

If the valve seat width exceeds the maximum

limit, remove enough stock from the top edge

and/or bottom edge of the seat to reduce the

width to specifications, and center.

On the valve seats of all engines, use a 60

degree angle grinding wheel to remove stock

from the bottom of the seats (raise the seats)

and use a 30 degree angle wheel to remove

stock from the top of the seats (lower the seats).

TO REMOVE

STOCK FROM

BOTTOM OF SEAT,

USE 60” WHEEL

TO REMOVE STOCK

FROM TOP OF SEAT,

I

USE 30” WHEEL

A81 97-B

REFACING VALVE SEATS

Refacing the valve seat should be closely co-

ordinated with the refacing of the valve face so

that the finished seat and valve face will be con-

centric and the specified interference fit will be

maintained. This is important so that the valve

and seat will have a compression-tight fit. Be

sure that the refacer grinding wheels are prop-

erly dressed.

VALVE SEAT

WIDTH

A8511-A

SEAT WIDTH SCALE

A8367-A

The finished valve seat should contact the ap-

proximate center of the valve face. It is good

practice to determine where the valve seat con-

tacts the face. To do this, coat the seat with

Prussian blue and set the valve in place. Rotate

the valve with light pressure. If the blue is trans-

ferred to the center of the valve face, the contact

is satisfactory. If the blue is transferred to the top

edge of the valve face, lower the valve seat. If

the blue is transferred to the bottom edge of the

valve face, raise the valve seat.

Loading...

Loading...