4-16

CHARGING

4-16

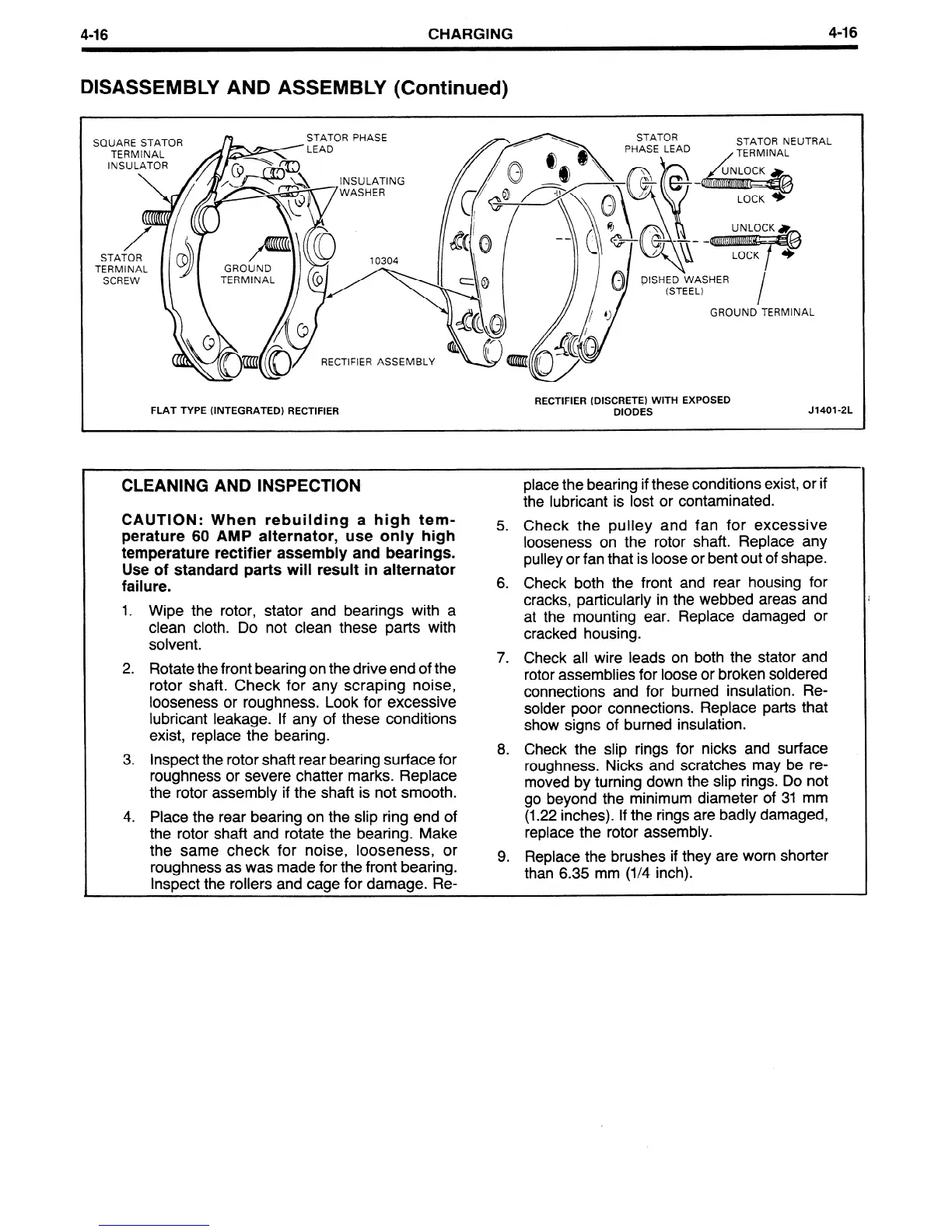

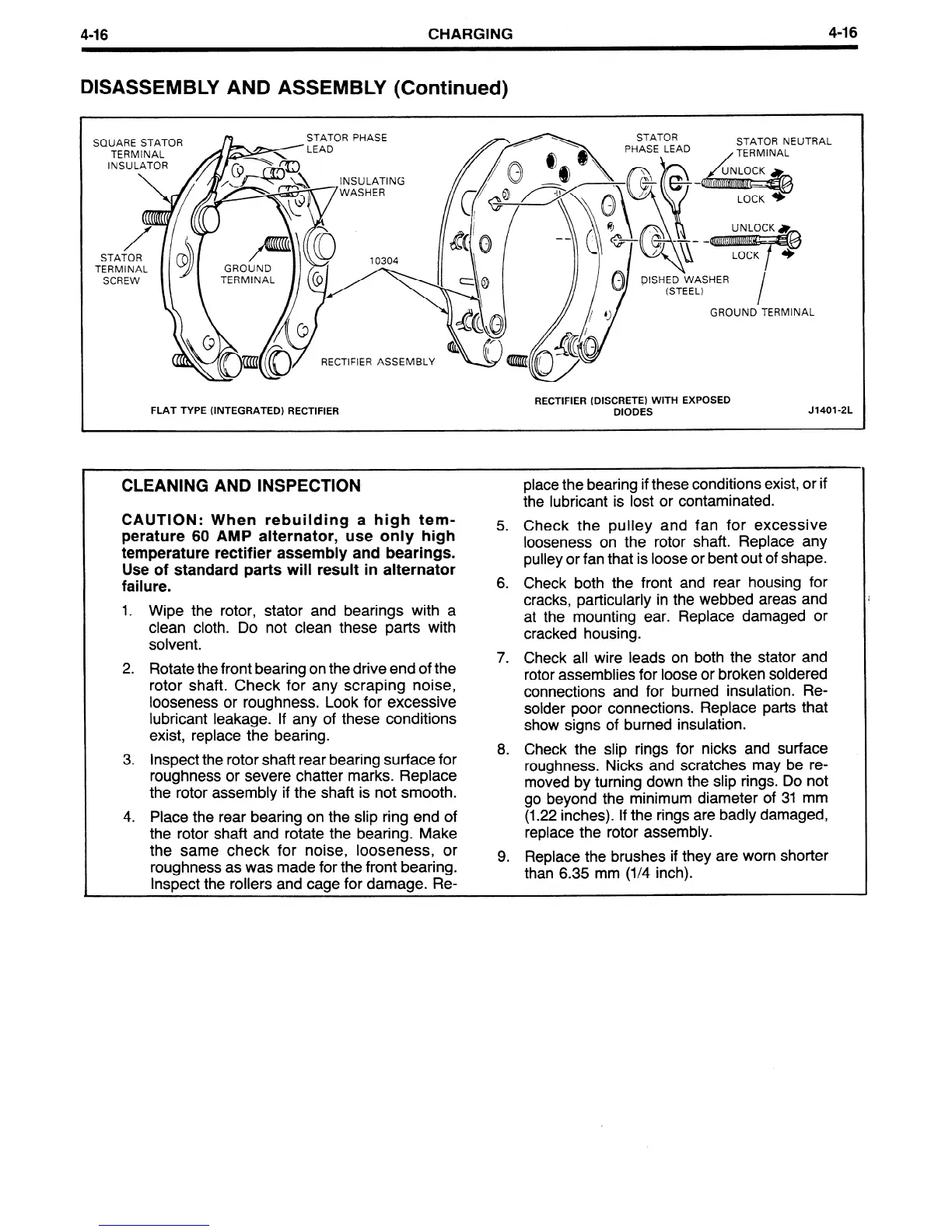

DISASSEMBLY AND ASSEMBLY (Continued)

INSULATING

GROUND TERMINAL

RECTIFIER ASSEMBLY

RECTIFIER (DISCRETE) WITH EXPOSED

FLAT TYPE (INTEGRATED) RECTIFIER DIODES

J1401-2L

CLEANING AND INSPECTION

CAUTION: When rebuilding a high tem-

perature 60 AMP alternator, use only high

temperature rectifier assembly and bearings.

Use of standard parts will result in alternator

failure.

1. Wipe the rotor, stator and bearings with a

clean cloth. Do not clean these parts with

solvent.

2. Rotate the front bearing on the drive end of the

rotor shaft. Check for any scraping noise,

looseness or roughness. Look for excessive

lubricant leakage. If any of these conditions

exist, replace the bearing.

3.

inspect the rotor shaft rear bearing surface for

roughness or severe chatter marks. Replace

the rotor assembly if the shaft is not smooth.

4.

Place the rear bearing on the slip ring end of

the rotor shaft and rotate the bearing. Make

the same check for noise, looseness, or

roughness as was made for the front bearing.

inspect the rollers and cage for damage. Re-

place the bearing if these conditions exist, or if

the lubricant is lost or contaminated.

5. Check the pulley and fan for excessive

looseness on the rotor shaft. Replace any

pulley or fan that is loose or bent out of shape.

6. Check both the front and rear housing for

cracks, particularly in the webbed areas and

at the mounting ear. Replace damaged or

cracked housing.

7. Check all wire leads on both the stator and

rotor assemblies for loose or broken soldered

connections and for burned insulation. Re-

solder poor connections. Replace parts that

show signs of burned insulation.

8. Check the slip rings for nicks and surface

roughness. Nicks and scratches may be re-

moved by turning down the slip rings. Do not

go beyond the minimum diameter of 31 mm

(1.22 inches). If the rings are badly damaged,

replace the rotor assembly.

9.

Replace the brushes if they are worn shorter

than 6.35 mm (l/4 inch).

Loading...

Loading...