I-43

BASIC ENGINE

1-43

REMOVAL AND INSTALLATION (Continued)

Main and connecting rod bearing inserts are

selective fits.

Selective fit bearings are available for service

in standard size, 0.001 and 0.002 inch under-

size. Undersize bearings (0.010, 0.020 and

0.030 inch), which are not selective fit, are avail-

able for use on crankshaft journals that have

been refinished.

Removal

1. Drain the crankcase. Remove the oil level

dipstick. Remove the oil pan and related

parts, following the procedure under Oil Pan-

Removal.

2. Remove the oil pump.

3. Replace one bearing at a time, leaving the

other bearings securely fastened. Remove

the main bearing cap to which new bearings

are to be installed.

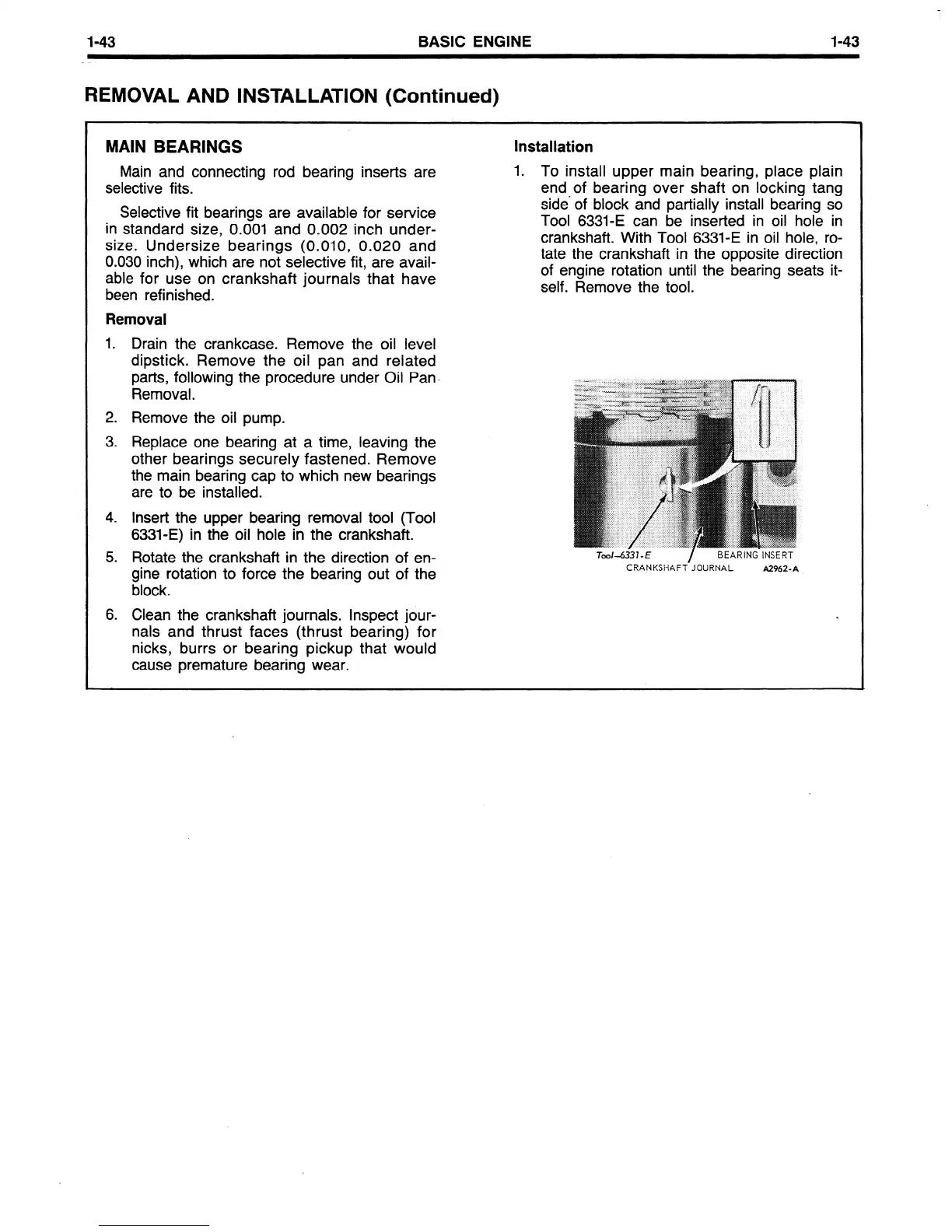

4.

Insert the upper bearing removal tool (Tool

6331-E) in the oil hole in the crankshaft.

5.

Rotate the crankshaft in the direction of en-

gine rotation to force the bearing out of the

block.

Installation

1. To install upper main bearing, place plain

end of bearing over shaft on locking tang

side’ of block and partially install bearing so

Tool 6331-E can be inserted in oil hole in

crankshaft. With Tool 6331-E in oil hole, ro-

tate the crankshaft in the opposite direction

of engine rotation until the bearing seats it-

self. Remove the tool.

CRANKSHAFT-JOURNAL

A2962-A

6. Clean the crankshaft journals. Inspect jour-

nals and thrust faces (thrust bearing) for

nicks, burrs or bearing pickup that would

cause premature bearing wear.

Loading...

Loading...