3-32

FUEL SYSTEM

3-32

MODEL 4160 CARBURETOR SYSTEMS (Continued)

CLEANING

Carburetor parts cleaning is covered on page

3-15.

NOTE: Cleaning, proper assembly, the use of

the correct parts, proper torquing of all

screws and correct adjustments are neces-

sary to achieve correct carburetor service.

Primary Metering Body

1. install idle mixture screw gaskets in pas-

sages. Use head of screw to push into

place.

NOTE: Inspect mixture screws. If the tapered

portion is grooved or ridged, a new mixture

screw should be installed to insure ability to

maintain the correct idle mixture. Turn

screws in lightly against their seats. Back

each screw out the exact number of turns re-

corded during disassembly.

2. Install a new gasket on power valve and in-

stall with proper wrench or socket. Torque to

100 in. Ibs.

3. Install main metering jets using proper

screwdriver or jet wrench.

4. Install fuel baffle (if used). Press metering

body and fuel bowl gasket down firmly on

the dowels.

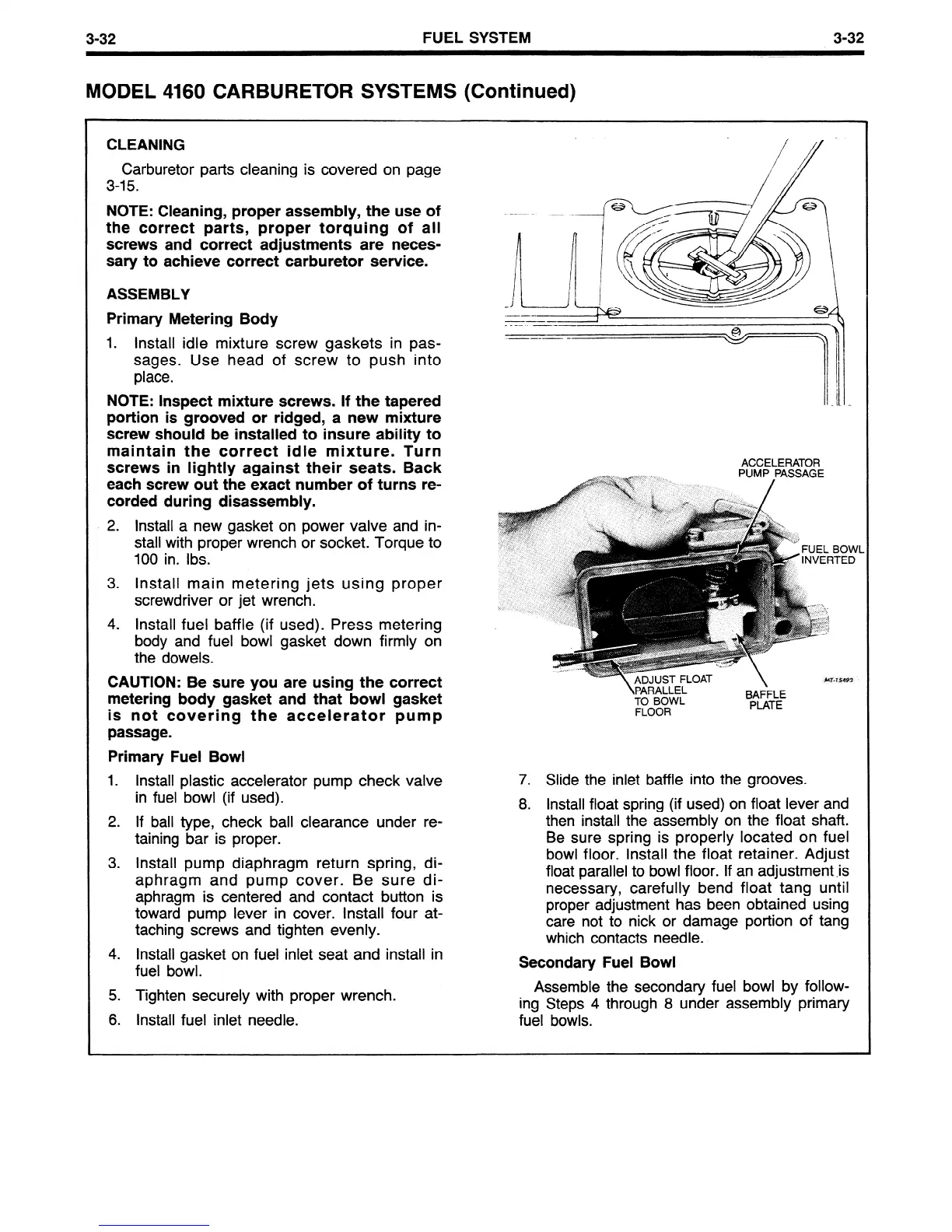

CAUTION: Be sure you are using the correct

metering body gasket and that bowl gasket

is not covering the accelerator pump

passage.

Primary Fuel Bowl

1. Install plastic accelerator pump check valve

in fuel bowl (if used).

2. If ball type, check ball clearance under re-

taining bar is proper.

3. Install pump diaphragm return spring, di-

aphragm and pump cover. Be sure di-

aphragm is centered and contact button is

toward pump lever in cover. Install four at-

taching screws and tighten evenly.

4. Install gasket on fuel inlet seat and install in

fuel bowl.

5. Tighten securely with proper wrench.

6. Install fuel inlet needle.

ACCELERATOR

\PARALLEL

TO BOWL

FLOOR

7. Slide the inlet baffle into the grooves.

8. Install float spring (if used) on float lever and

then install the assembly on the float shaft.

Be sure spring is properly located on fuel

bowl floor. Install the float retainer. Adjust

float parallel to bowl floor. If an adjustmentis

necessary, carefully bend float tang until

proper adjustment has been obtained using

care not to nick or damage portion of tang

which contacts needle.

Secondary Fuel Bowl

Assemble the secondary fuel bowl by follow-

ing Steps 4 through 8 under assembly primary

fuel bowls.

Loading...

Loading...