I-26

BASIC ENGINE

. 1-26

OVERHAUL (Continued)

The following procedure should be used to re-

pair porous areas or sand holes in cast iron:

a. Clean the surface to be repaired by grind-

ing or rotary filing to a clean bright metal

surface. Chamfer or undercut the hole or

porosity to a greater depth than the rest

of the cleaned surface. Solid metal must

surround the hole. Openings larger than

l/4 inch should not be repaired using me-

tallic plastic. Openings in excess of l/4

inch can be drilled, tapped and plugged

using common tools. Clean the repair

area thoroughly. Metallic plastic will not

stick to a dirty or oily surface.

b. Mix the metallic plastic base and hard-

ener as directed on the container. Stir

thoroughly until uniform.

c. Apply the repair mixture with a suitable

clean tool (putty knife, wood spoon, etc.)

forcing the epoxy into the hole or porosity.

d. Allow the repair mixture to harden. This

can be accomplished by two methods:

heat cure with a 250 degree watt lamp

placed IO inches from the repaired sur-

face, or air dry for lo-12 hours at tem-

peratures above 50 degrees F.

e. Sand or grind the repaired area to blend

with the general contour of the surround-

ing surface.

face to match the rest of the

f. Paint the sur

block.

--

ADJUSTMENTS

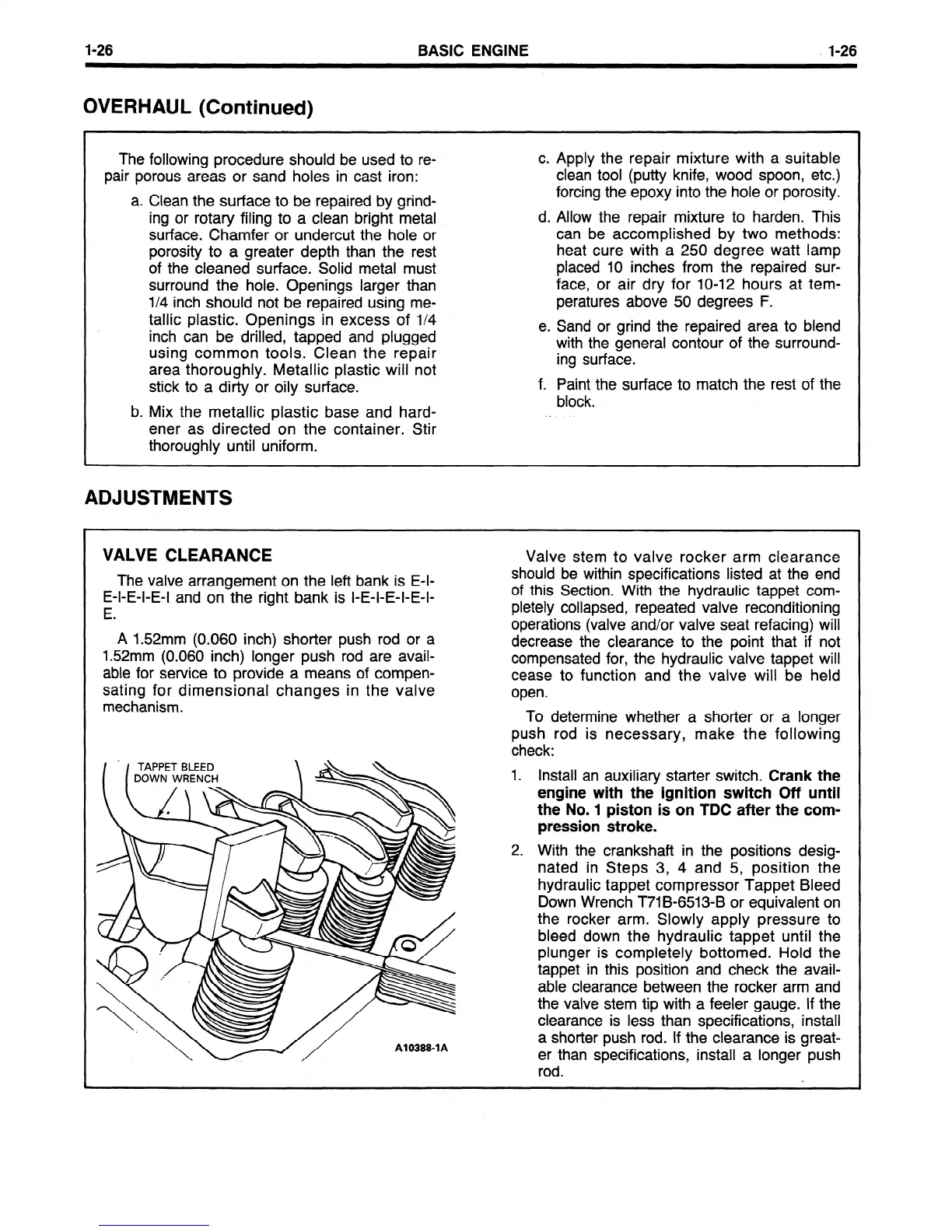

VALVE CLEARANCE

The valve arrangement on the left bank is E-l-

E-I-E-I-E-I and on the right bank is I-E-I-E-I-E-I-

E

.

A 1.52mm (0.060 inch) shorter push rod or a

1.52mm (0.060 inch) longer push rod are avail-

able for service to provide a means of compen-

sating for dimensional changes in the valve

mechanism.

Valve stem to valve rocker arm clearance

should be within specifications listed at the end

of this Section. With the hydraulic tappet com-

pletely collapsed, repeated valve reconditioning

operations (valve and/or valve seat refacing) will

decrease the clearance to the point that if not

compensated for, the hydraulic valve tappet will

cease to function and the valve will be held

open.

To determine whether a shorter or a longer

push rod is necessary, make the following

check:

1. Install an auxiliary starter switch.

Crank the

engine with the ignition switch Off until

the No. 1 piston is on TDC after the com-

pression stroke.

2. With the crankshaft in the positions desig-

nated in Steps 3, 4 and 5, position the

hydraulic tappet compressor Tappet Bleed

Down Wrench T71B-6513-B or equivalent on

the rocker arm. Slowly apply pressure to

bleed down the hydraulic tappet until the

plunger is completely bottomed. Hold the

tappet in this position and check the avail-

able clearance between the rocker arm and

the valve stem tip with a feeler gauge. If the

clearance is less than specifications, install

a shorter push rod. If the clearance is great-

er than specifications, install a longer push

rod.

Loading...

Loading...