1-44

BASIC ENGINE

1-44

REMOVAL AND INSTALLATION (Continued)

2. Fit the main bearings as detailed on Page

1-23 under Fitting Bearings with Plastigage.

3.

After the bearing has been fitted, apply light

coat of engine oil to journal and bearings.

Install the bearing cap. Tighten the cap bolts

to specifications.

4. Repeat the procedure for remaining bear-

ings that require replacement.

5. If the rear main bearing is to be replaced,

remove the rear main bearing cap. Remove

and discard the rear oil seal.

6. Clean rear journal oil seal groove and mat-

ing surfaces of block and rear main bearing

cap.

7. Install the new seal.

8. Seal the rear main bearing cap. After seal-

ing, install the rear main bearing cap and

tighten cap bolts to specifications.

:: .’

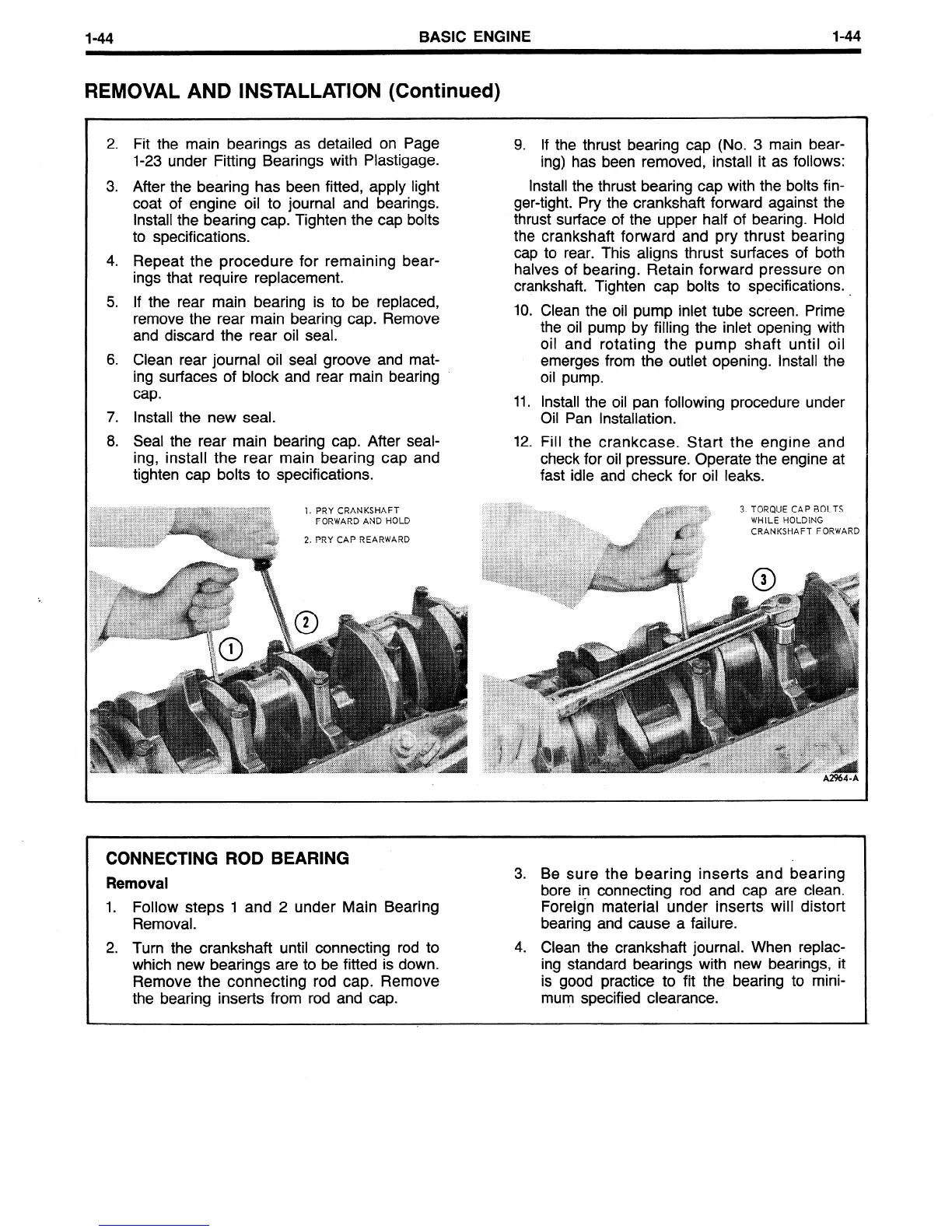

1. PRY CRANKSHAFT

,.

FORWARD AND HOLD

2. PRY CAP REARWARD

9. If the thrust bearing cap (No. 3 main bear-

ing) has been removed, install it as follows:

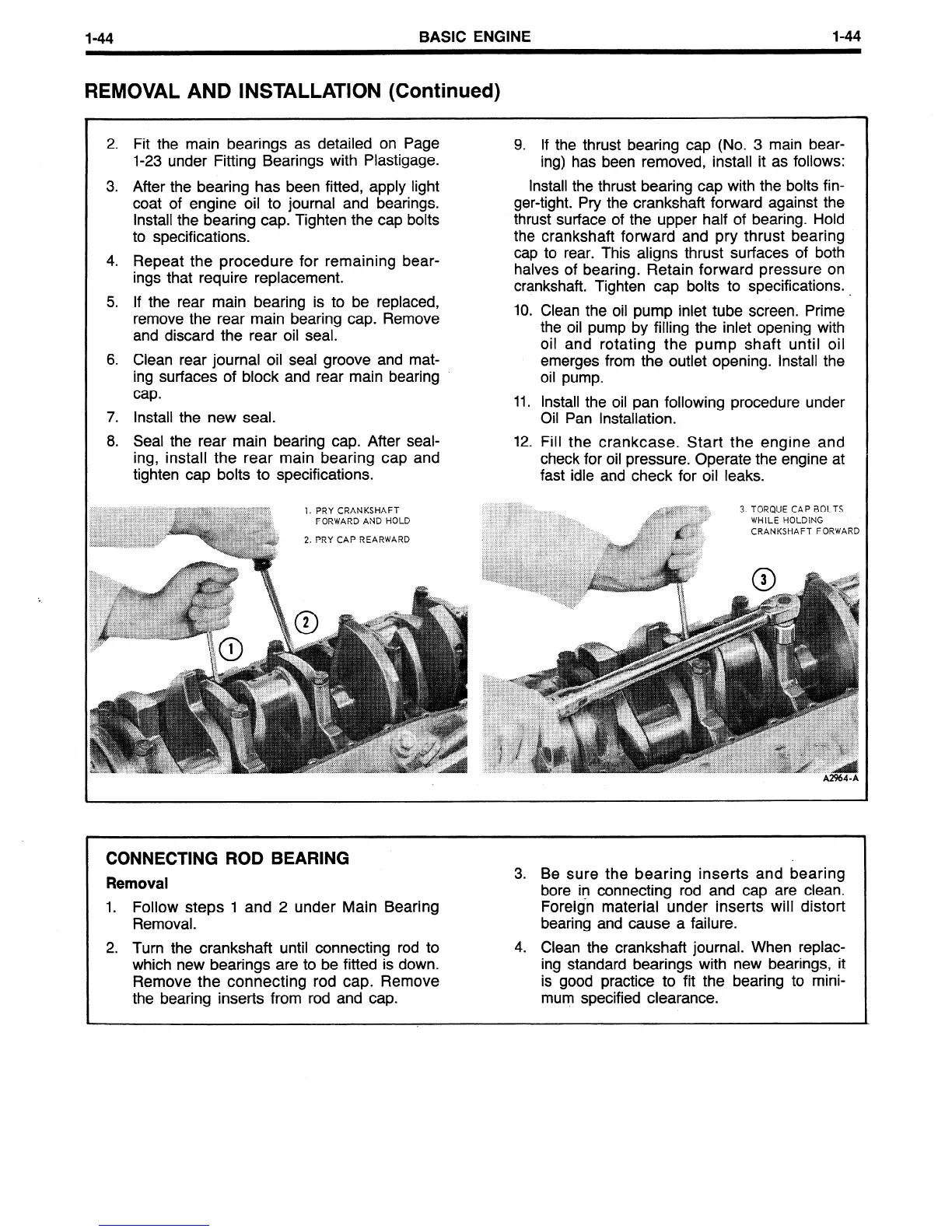

Install the thrust bearing cap with the bolts fin-

ger-tight. Pry the crankshaft forward against the

thrust surface of the upper half of bearing. Hold

the crankshaft forward and pry thrust bearing

cap to rear. This aligns thrust surfaces of both

halves of bearing. Retain forward pressure on

crankshaft. Tighten cap bolts to specifications.

.

IO. Clean the oil pump inlet tube screen. Prime

the oil pump by filling the inlet opening with

oil and rotating the pump shaft until oil

emerges from the outlet opening. Install the

oil pump.

11. Install the oil pan following procedure under

Oil Pan Installation.

12. Fill the crankcase. Start the engine and

check for oil pressure. Operate the engine at

fast idle and check for oil leaks.

3. TORQUE CAP 8OLTS

WHILE HOLDING

CRANKSHAFT FORWARD

CONNECTING ROD BEARING

Removal

1. Follow steps 1

and 2

under Main Bearing

Removal.

2. Turn the crankshaft until connecting rod to

which new bearings are to be fitted is down.

Remove the connecting rod cap. Remove

the bearing inserts from rod and cap.

3. Be sure the bearing inserts and bearing

bore in connecting rod and cap are clean.

Foreign material under inserts will distort

bearing and cause a failure.

4. Clean the crankshaft journal. When replac-

ing standard bearings with new bearings, it

is good practice to fit the bearing to mini-

mum specified clearance.

Loading...

Loading...