3-10

FUEL SYSTEM

3-10

MODEL 2300 24 CARBURETOR (Continued)

ERRATIC ENGINE IDLE

If the engine idle is erratic or rough after cor-

rect idle adjustment, check the following items:

1.

Recheck spark plugs and spark plug wires.

Be sure all cylinders are firing. A missing

cylinder or occasional misfire will turn an en-

gine that is a minor emitter into a gross

emitter.

2. Check for vacuum leaks (vacuum lines or

manifold).

LOW IDLE SPEED ADJUSTMENT

With engine at correct operating temperature

and condition as in above procedure and curb

idle adjusted to specifications, proceed as

follows:

1. Set the low idle speed to specifications by

adjusting the low idle speed adjusting screw.

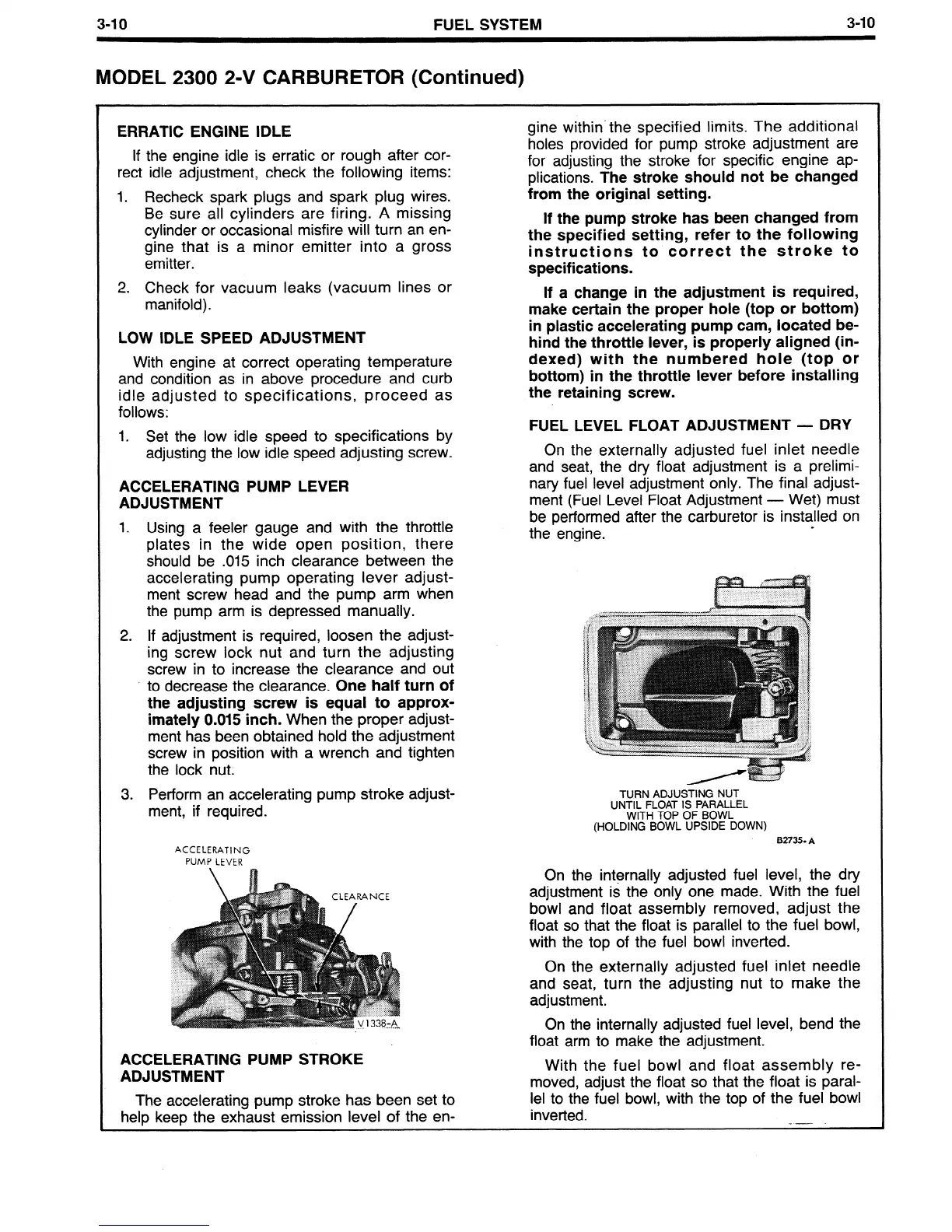

ACCELERATING PUMP LEVER

ADJUSTMENT

1. Using a feeler gauge and with the throttle

plates in the wide open position, there

should be .015 inch clearance between the

accelerating pump operating lever adjust-

ment screw head and the pump arm when

the pump arm is depressed manually.

2. If adjustment is required, loosen the adjust-

ing screw lock nut and turn the adjusting

screw in to increase the clearance and out

- to decrease the clearance.

One half turn of

the adjusting screw is equal to approx-

imately 0.015 inch.

When the proper adjust-

ment has been obtained hold the adjustment

screw in position with a wrench and tighten

the lock nut.

3. Perform an accelerating pump stroke adjust-

ment, if required.

ACCELERATING

PUMP LEVER

ACCELERATING PUMP STROKE

ADJUSTMENT

The accelerating pump stroke has been set to

help keep the exhaust emission level of the en-

gine within’the specified limits. The additional

holes provided for pump stroke adjustment are

for adjusting the stroke for specific engine ap-

plications.

The stroke should not be changed

from the original setting.

If the pump stroke has been changed from

the specified setting, refer to the following

instructions to correct the stroke to

specifications.

If a change in the adjustment is required,

make certain the proper hole (top or bottom)

in plastic accelerating pump cam, located be-

hind the throttle lever, is properly aligned (in-

dexed) with the numbered hole (top or

bottom) in the throttle lever before installing

the retaining screw.

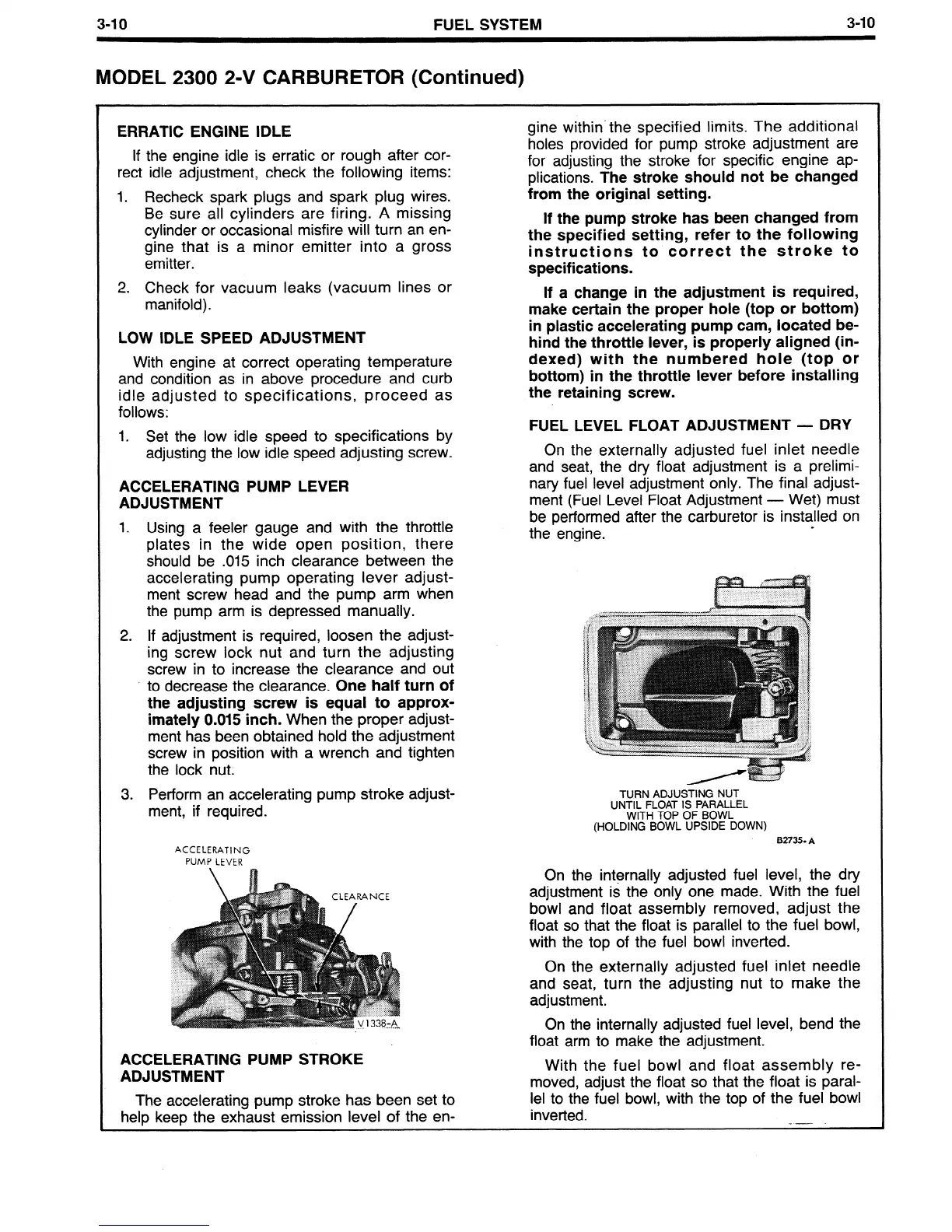

FUEL LEVEL FLOAT ADJUSTMENT - DRY

On the externally adjusted fuel inlet needle

and seat, the dry float adjustment is a prelimi-

nary fuel level adjustment only. The final adjust-

ment (Fuel Level Float Adjustment - Wet) must

be performed after the carburetor is installed on

the engine.

.

TURN ADJUSTING NUT

UNTIL FLOAT IS PARALLEL

WITH TOP OF BOWL

(HOLDING BOWL UPSIDE DOWN)

82735

A

On the internally adjusted fuel level, the dry

adjustment is the only one made. With the fuel

bowl and float assembly removed, adjust the

float so that the float is parallel to the fuel bowl,

with the top of the fuel bowl inverted.

On the externally adjusted fuel inlet needle

and seat, turn the adjusting nut to make the

adjustment.

On the internally adjusted fuel level, bend the

float arm to make the adjustment.

With the fuel bowl and float assembly re-

moved, adjust the float so that the float is paral-

lel to the fuel bowl, with the top of the fuel bowl

inverted.

-- -

Loading...

Loading...