I-09

BASIC ENGINE

I-09

DIAGNOSIS AND TESTING (Continued)

HYDRAULIC VALVE LIFTER

Dirt, deposits of gum and varnish and air bub-

bles in the lubricating oil can cause hydraulic

valve lifter failure or malfunction.

Dirt, gum and varnish can keep a check

valve from seating and cause a loss of

hydraulic pressure.

An open valve disc will

c&se the plunger to force oil back into the valve

lifter reservoir during the time the push rod is

being lifted to force the valve from its seat.

Air bubbles in the lubricating system can be

caused by too much oil in the system or too low

an oil level. Air may also be drawn into the lubri-

cating system through an opening in a damaged

oil pick-up tube. Air in the hydraulic system can

cause a loss of hydraulic pressure.

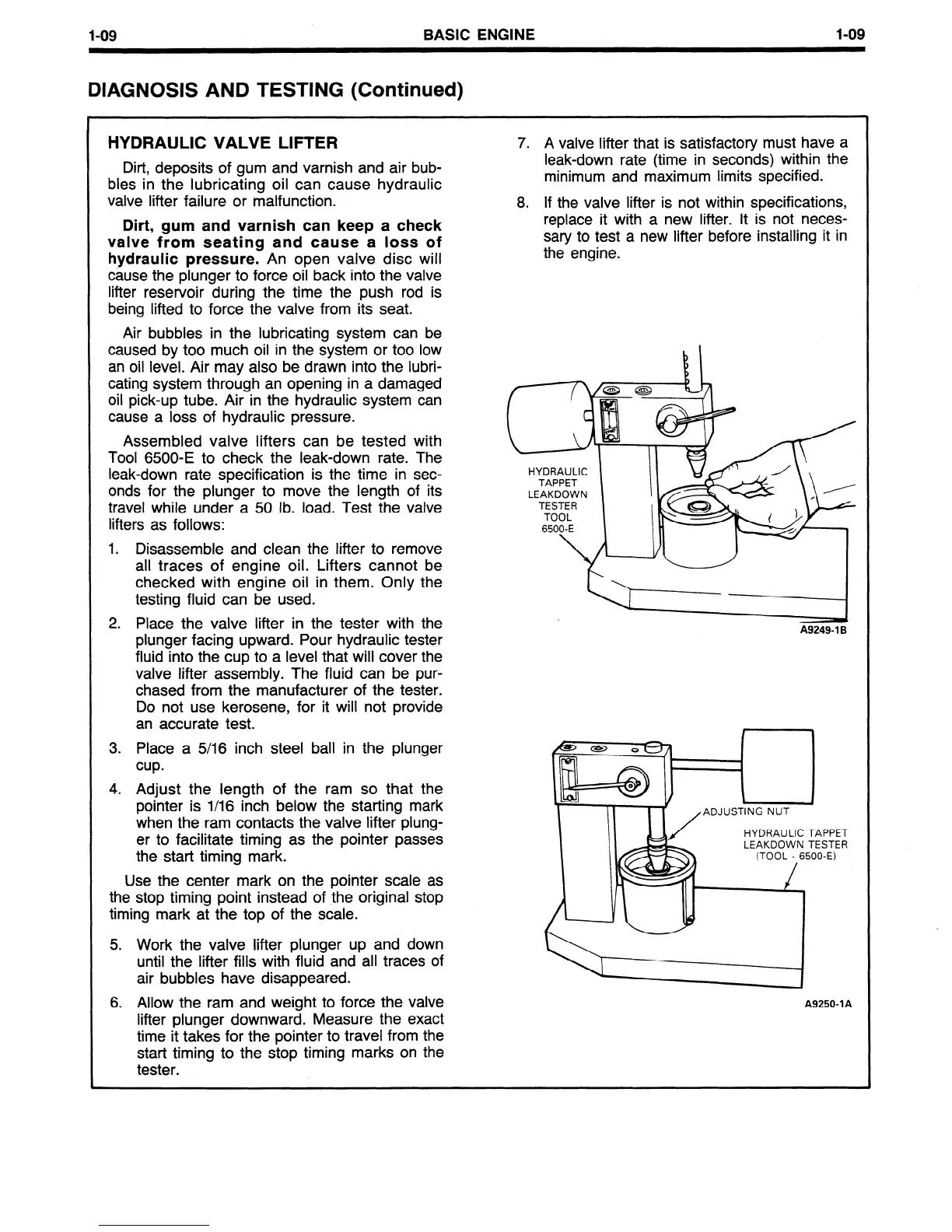

Assembled valve lifters can be tested with

Tool 6500-E to check the leak-down rate. The

leak-down rate specification is the time in sec-

onds for the plunger to move the length of its

travel while under a 50 lb. load. Test the valve

lifters as follows:

1. Disassemble and clean the lifter to remove

all traces of engine oil. Lifters cannot be

checked with engine oil in them. Only the

testing fluid can be used.

2. Place the valve lifter in the tester with the

plunger facing upward. Pour hydraulic tester

fluid into the cup to a level that will cover the

valve lifter assembly. The fluid can be pur-

chased from the manufacturer of the tester.

Do not use kerosene, for it will not provide

an accurate test.

3. Place a 5/16 inch steel ball in the plunger

cup.

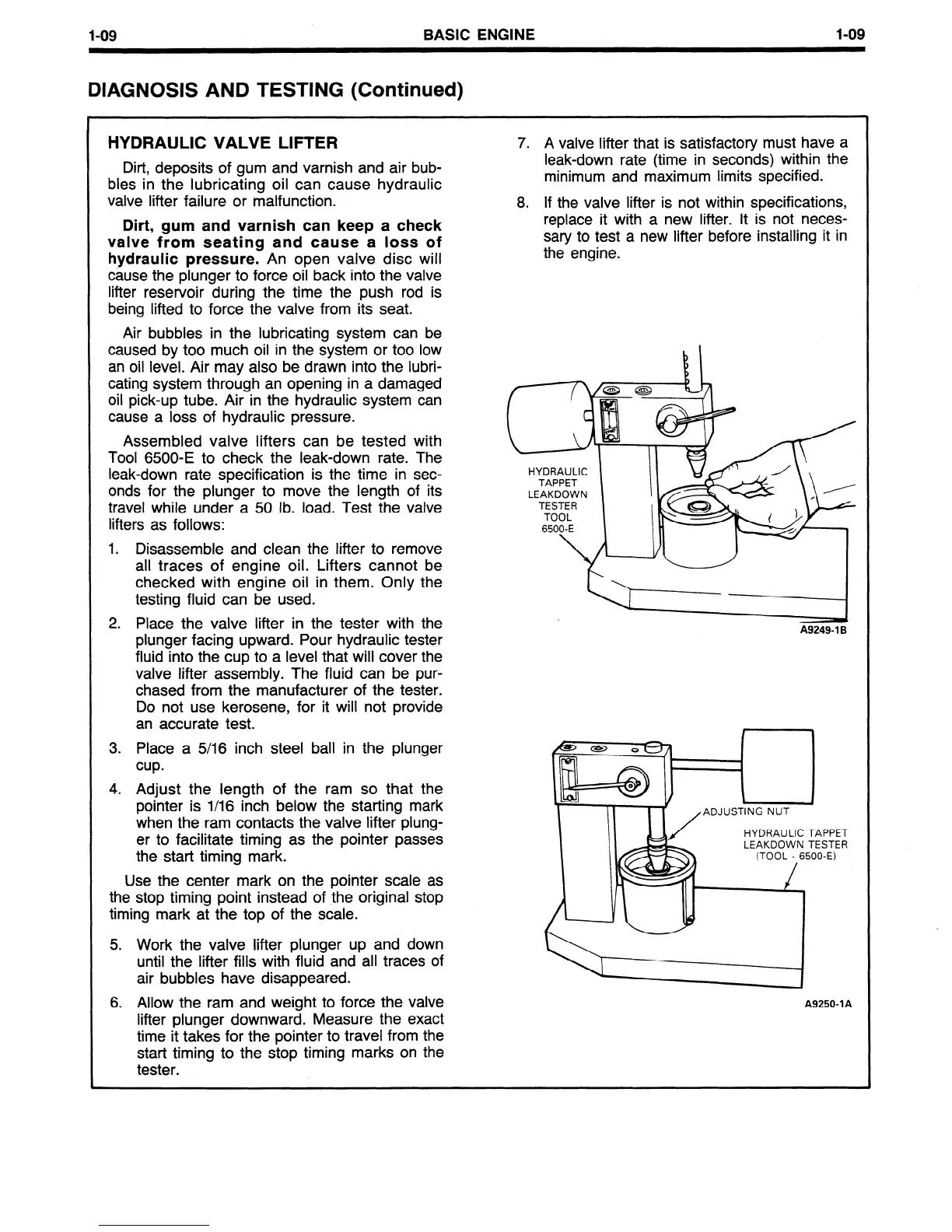

4. Adjust the length of the ram so that the

pointer is l/16 inch below the starting mark

when the ram contacts the valve lifter plung-

er to facilitate timing as the pointer passes

the start timing mark.

Use the center mark on the pointer scale as

the stop timing point instead of the original stop

timing mark at the top of the scale.

5. Work the valve lifter plunger up and down

until the lifter fills with fluid and all traces of

air bubbles have disappeared.

6. Allow the ram and weight to force the valve

lifter plunger downward. Measure the exact

time it takes for the pointer to travel from the

start timing to the stop timing marks on the

tester.

7. A valve lifter that is satisfactory must have a

leak-down rate (time in seconds) within the

minimum and maximum limits specified.

8. If the valve lifter is not within specifications,

replace it with a new lifter. It is not neces-

sary to test a new lifter before installing it in

the engine.

b \

HYDRAULIC

TAPPET

LEAKDOWN

6500-E 1

HI -

A9249- 1 B

LEAKDOWN TESTE

FE3 I

(TOOL - 6500-E)

:T

R

A9250-1 A

Loading...

Loading...