l-42 BASIC ENGINE

1-42

REMOVAL AND INSTALLATION (Continued)

Installation

1. Carefully clean the seal groove in the cap

and block with a brush and solvent.

2. Dip the split lip-type seal halves in clean en-

gine oil.

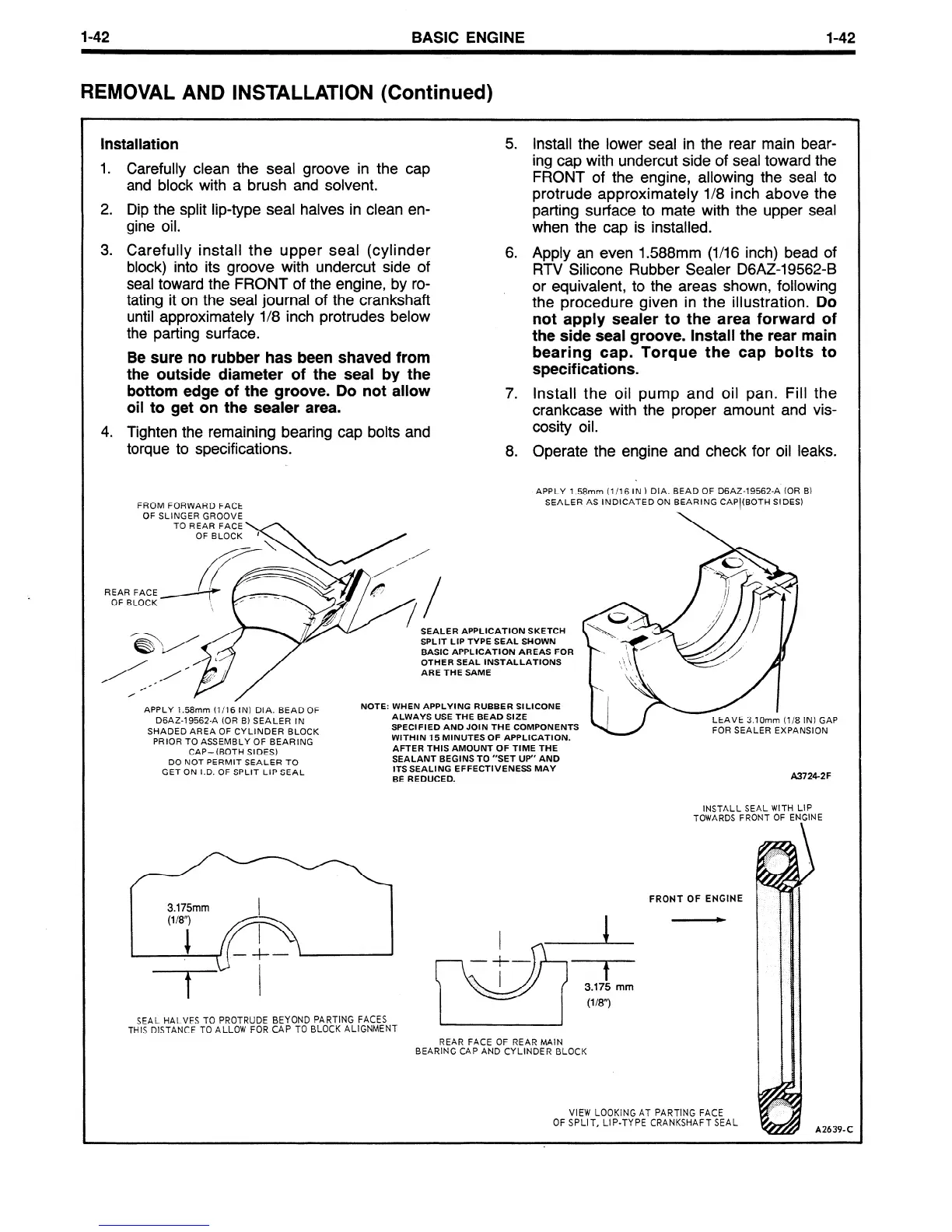

3. Carefully install the upper seal (cylinder

block) into its groove with undercut side of

seal toward the FRONT of the engine, by ro-

tating it on the seal journal of the crankshaft

until approximately l/8 inch protrudes below

the parting surface.

Be sure no rubber has been shaved from

the outside diameter of the seal by the

bottom edge of the groove. Do not allow

oil to get on the sealer area.

4. Tighten the remaining bearing cap bolts and

torque to specifications.

5 .

Install the lower seal in the rear main bear-

ing cap with undercut side of seal toward the

FRONT of the engine, allowing the seal to

protrude approximately l/8 inch above the

parting surface to mate with the upper seal

when the cap is installed.

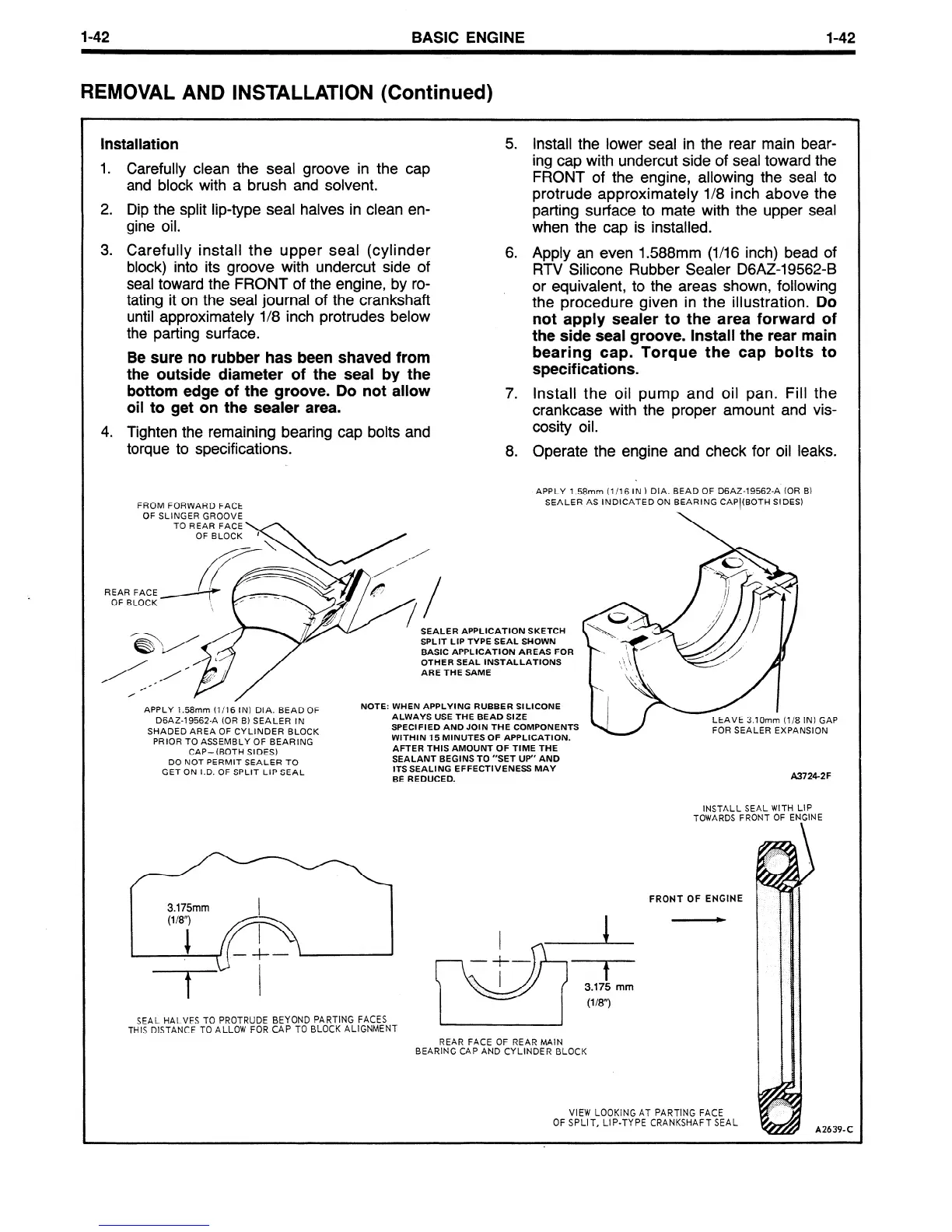

6. Apply an even 1.588mm (l/16 inch) bead of

RTV Silicone Rubber Sealer DGAZ-19562-B

or equivalent, to the areas shown, following

the procedure given in the illustration.

Do

not apply sealer to the area forward of

the side seal groove. Install the rear main

bearing cap. Torque the cap bolts to

specifications.

7. Install the oil pump and oil pan. Fill the

crankcase with the proper amount and vis-

cosity oil.

8.

Operate the engine and check for oil leaks.

APPLY 1.58mm (l/16 IN 1 DIA. BEAD OF D6AZ-19562-A (OR B)

FROM FORWARD FACE

SEALER AS INDICATED ON BEARING CAPItBOTH SIDES)

OF SLINGER GROOVE

SEALER APPLICATION SKETCH

SPLIT LIP TYPE SEAL SHOWN

BASIC APPLICATION AREAS FOR

OTHER SEAL INSTALLATIONS

ARE THE SAME

APPLY

1.58mm (l/16 IN) DIA. BEAD OF

DGAZ-19562-A (OR B) SEALER IN

SHADED AREA

OF CYLINDER BLOCK

PRIOR TO ASSEMBLY OF BEARING

CAP-(BOTH SIDES)

DO NOT PERMIT SEALER TO

GET ON I.D. OF

SPLIT LIP SEAL

NOTE: WHEN APPLYING RUBBER SILICONE

ALWAYS USE THE BEAD SIZE

SPECIFIED AND JOIN THE COMPONENTS

WITHIN 15 MINUTES OF APPLICATION.

AFTER THIS AMOUNT OF TIME THE

SEALANT BEGINS TO “SET UP” AND

ITS SEALING EFFECTIVENESS MAY

BE REDUCED.

LEAVE 3.10mm (l/8 IN) GAP

FOR SEALER EXPANSION

A3724-2F

INSTALL SEAL WITH LIP

TOWARDS FRONT OF

ENFINE

3.175mm

SEAL HALVES TO PROTRUDE BEYOND PARTING

FACES

THIS DISTANCE TO ALLOW FOR CAP TO BLOCK ALIGNMENT

FRONT OF ENGINE

+

A

T-l

I

- f

3.175 mm

(l/8”)

REAR FACE OF REAR MAIN

BEARING CAP AND CYLINDER BLOCK

VIEW LOOKING AT PARTING FACE

OF SPLIT, LIP-TYPE CRANKSHAFT SEAL

A2639-C

Loading...

Loading...