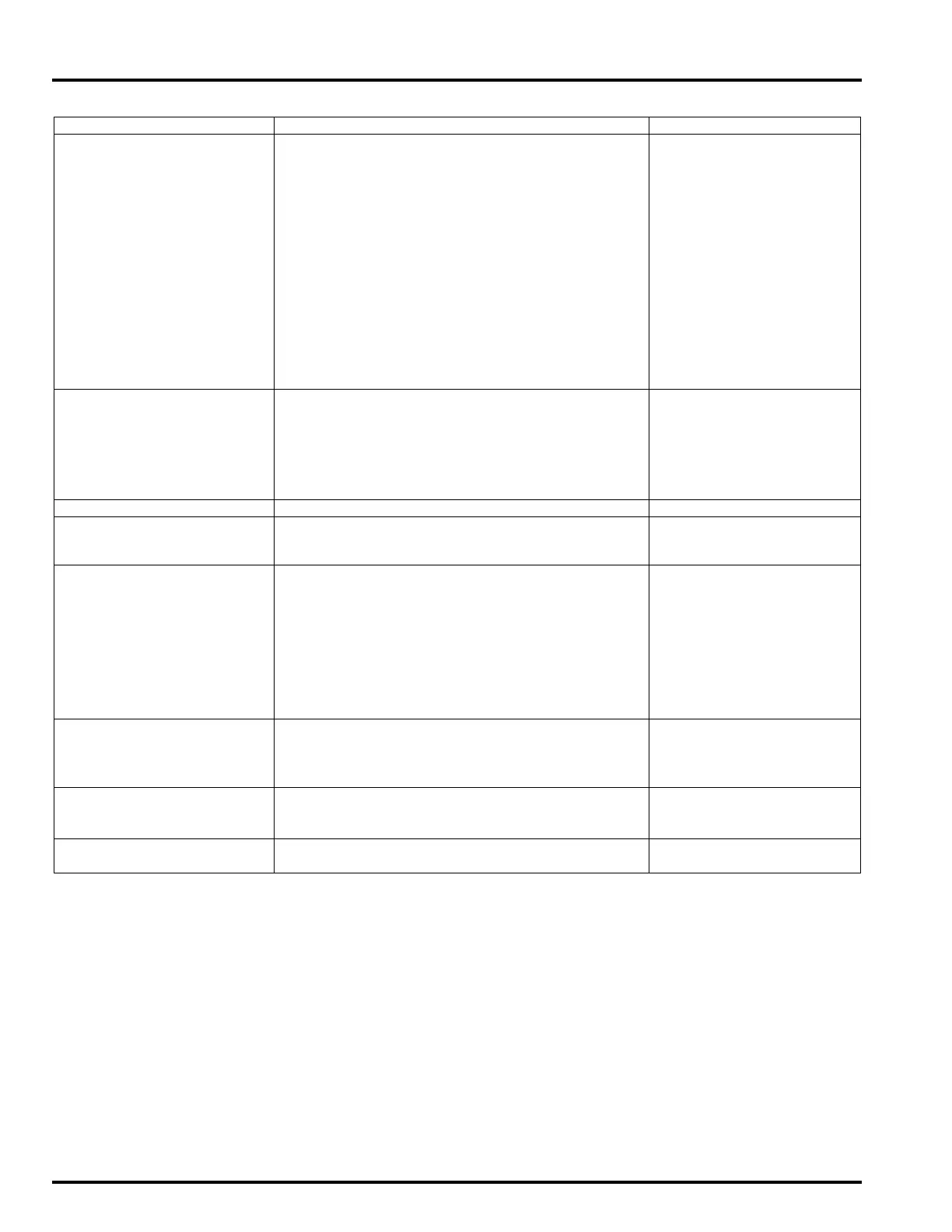

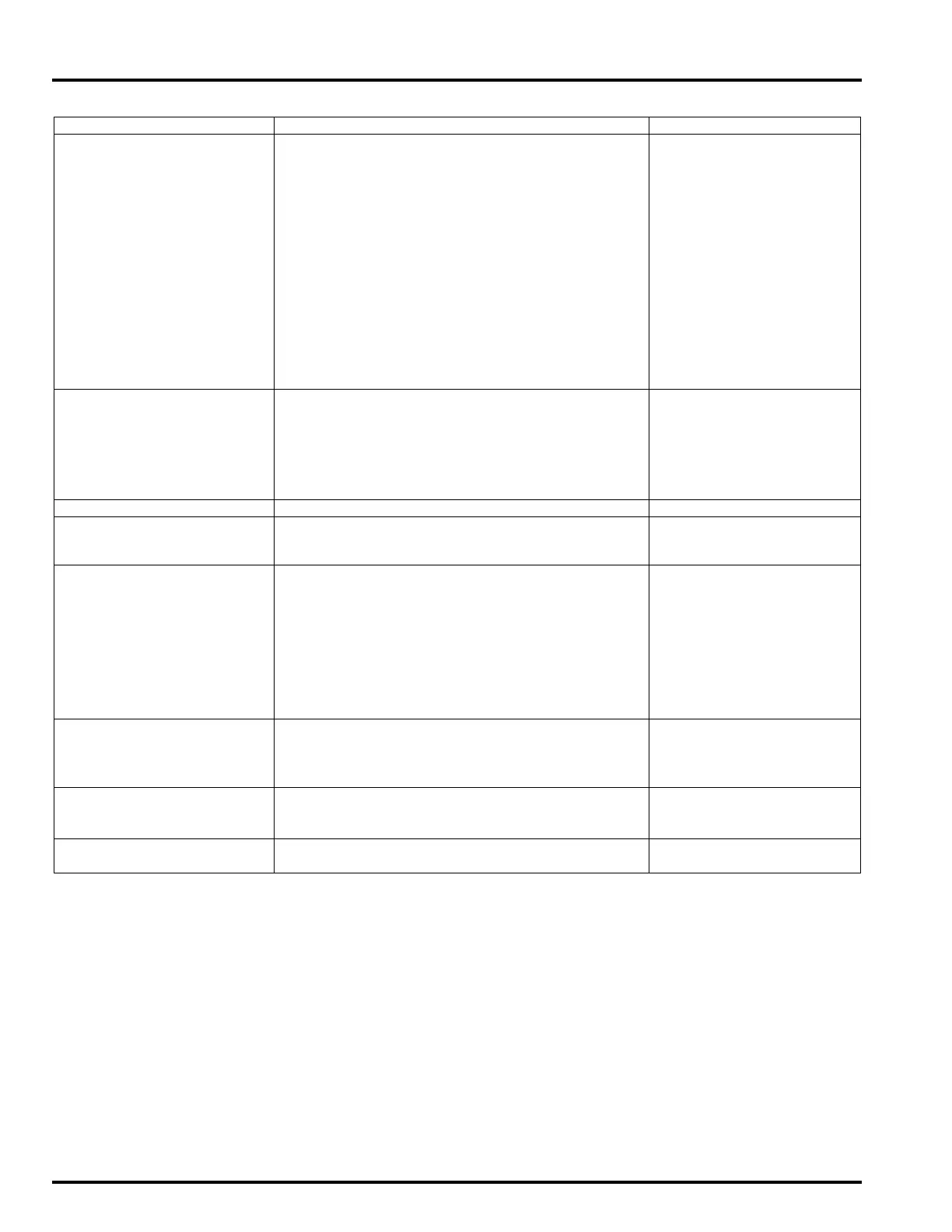

GENERAL INFORMATION

1-18

FRAME

MATERIAL LOCATION REMARKS

Multi-purpose grease Seat catch sliding area Apply 1.5 g minimum

Sidestand pivot sliding area

Centerstand pivot inside Apply 3.0 g minimum

Centerstand shaft sliding surface

Throttle grip pipe flange cable groove Apply 0.1 – 0.2 g

Engine hanger bracket B needle bearing

Engine hanger bracket B inner collar outer surface

Engine hanger bracket B dust seal lips

Front wheel dust seal lips

Front wheel bearing whole surface

Swingarm dust seal lips

Passenger footpeg contact area

Final shaft outer surface (swingarm bearing fitting

area)

Final shaft groove Apply 0.03 – 0.04 g

Urea based multi-purpose

grease with extreme pres-

sure agent (example:

EXCELITE EP2 manufac-

tured by KYODO YUSHI,

Japan), Shell Stamina EP2

or equivalent

Steering head bearings Apply 3 – 5 g each

Steering head dust seal lips

Engine oil Fuel pump rubber seal inner surface Apply 1.0 g maximum

Honda bond A, Honda hand

grip cement, Cemedine #540

or equivalent

Handlebar grip rubber inside

Brake caliper bracket pad retainer

Silicone grease Throttle cable inside Apply 0.2 g minimum

Throttle cable boot inside Apply 0.1 cc

Brake master cylinder piston boot inner surface

Brake lever contacting area with piston Apply 0.1 g

Brake lever pivot sliding area Apply 0.1 g

Pad pin stopper ring outer surface

Brake caliper dust seal

Brake caliper pin sliding area and boot Apply 0.4 g minimum

Brake caliper bracket pin sliding area and boot Apply 0.4 g minimum

DOT 4 brake fluid Master cylinder piston outer surface and cup

Caliper piston whole surface

Caliper piston seal whole surface

Brake pipe joint nut threads

Fork fluid Fork oil seal lips

Fork dust seal lips

Spring seat O-ring

Locking agent Fork socket bolt threads

Sensor protector socket bolt threads

Loading...

Loading...