.

MAINTENANCE

SERVICE PROCEDURE

EVERY 250 HOURS SERVICE

LUBRICATING

1. Lower the work equipment to the ground, then stop the engine.

2.

Using a grease pump, pump in grease through the grease fittings shown by arrows.

3.

After greasing, wipe off any old grease that was pushed out.

Grease equalizer bar side pin (4 places)

Left and right sides of machine: 2 places each

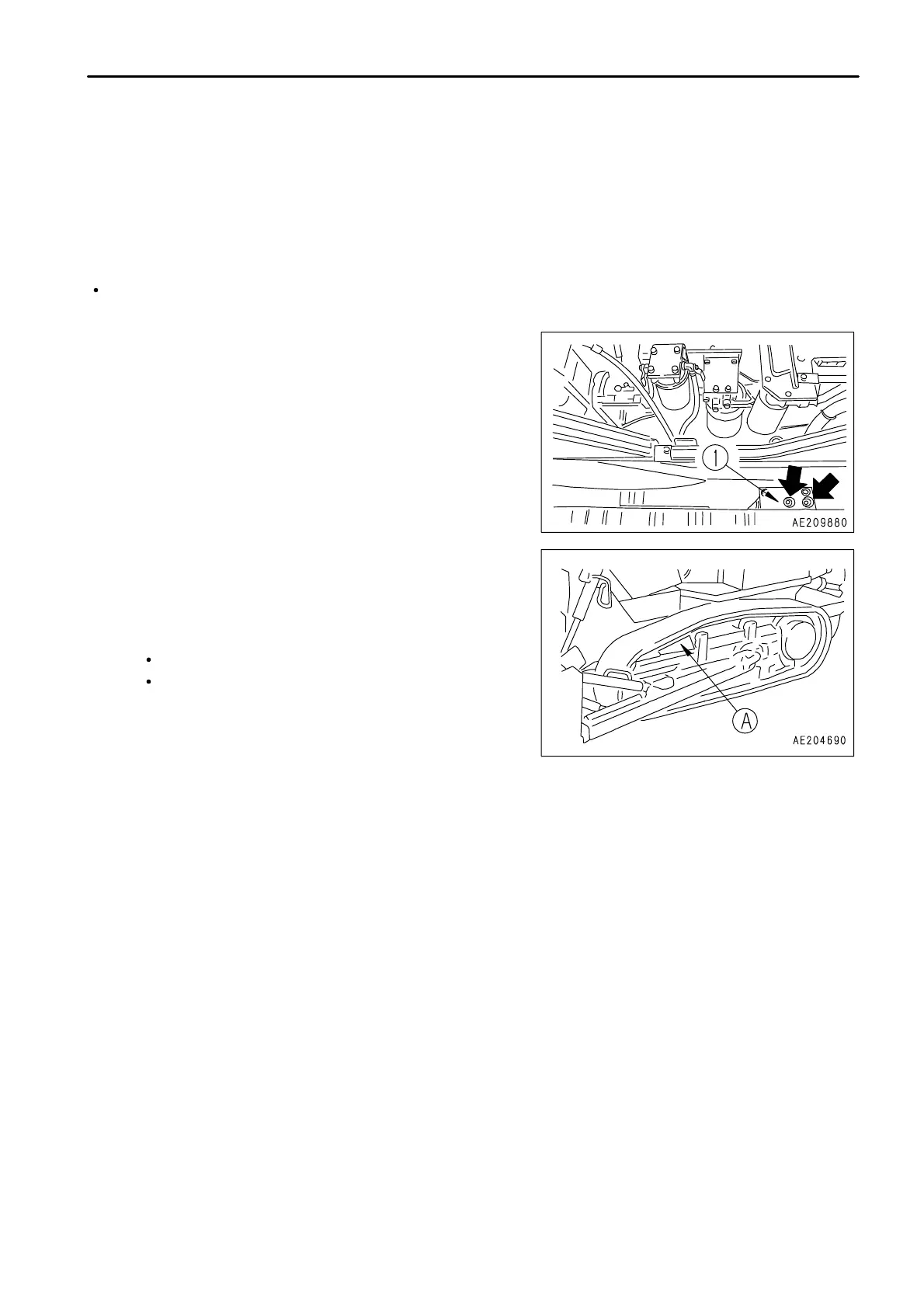

1) Remove all soil and mud from the top of track frame and

cover (1).

2)

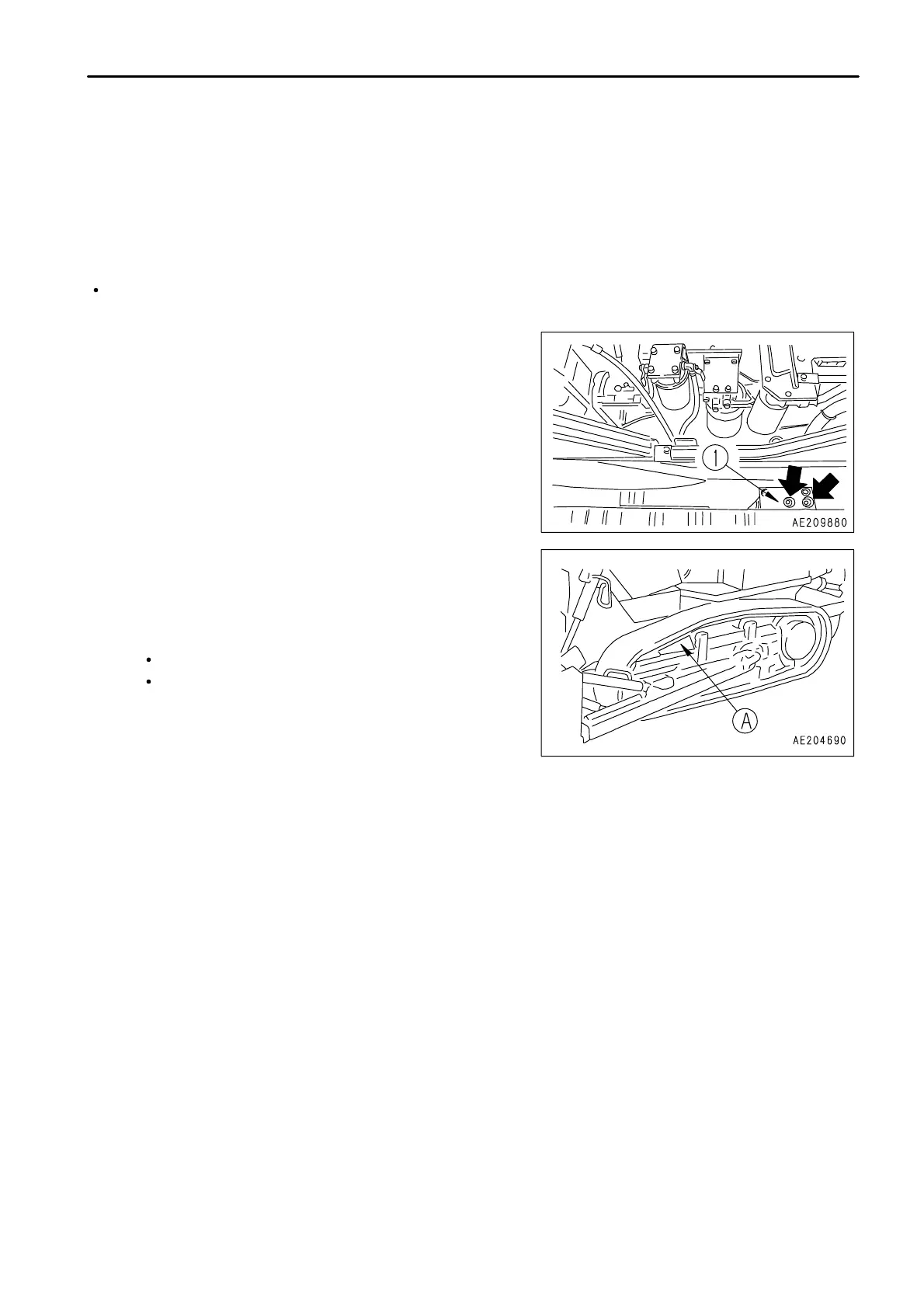

Climb on top of the straight frame and remove the red plug

from (A) between the track frame and track shoe.

3) Carry out the greasing from the top of the track shoe.

Parts to use (supplied parts)

Grease pump ass'y (07952-80002)

Nozzle (07951-41043): Tube type

4 - 43

Loading...

Loading...