1-S48

F2880, F3680, RCK72-F36, RCK72R-F36, RCK60-F36, RCK60R-F36, WSM

ENGINE

(4) Crankshaft

Crankshaft Side Clearance

1. Set a dial indicator with its tip on the end of the crankshaft.

2. Measure the side clearance by moving the crankshaft to the front

and rear.

3. If the measurement exceeds the allowable limit, replace the

thrust bearings.

4. If the same size bearing is still loose because of the crankshaft

journal wear, replace it with an oversize one referring to the table

and figure.

(Reference)

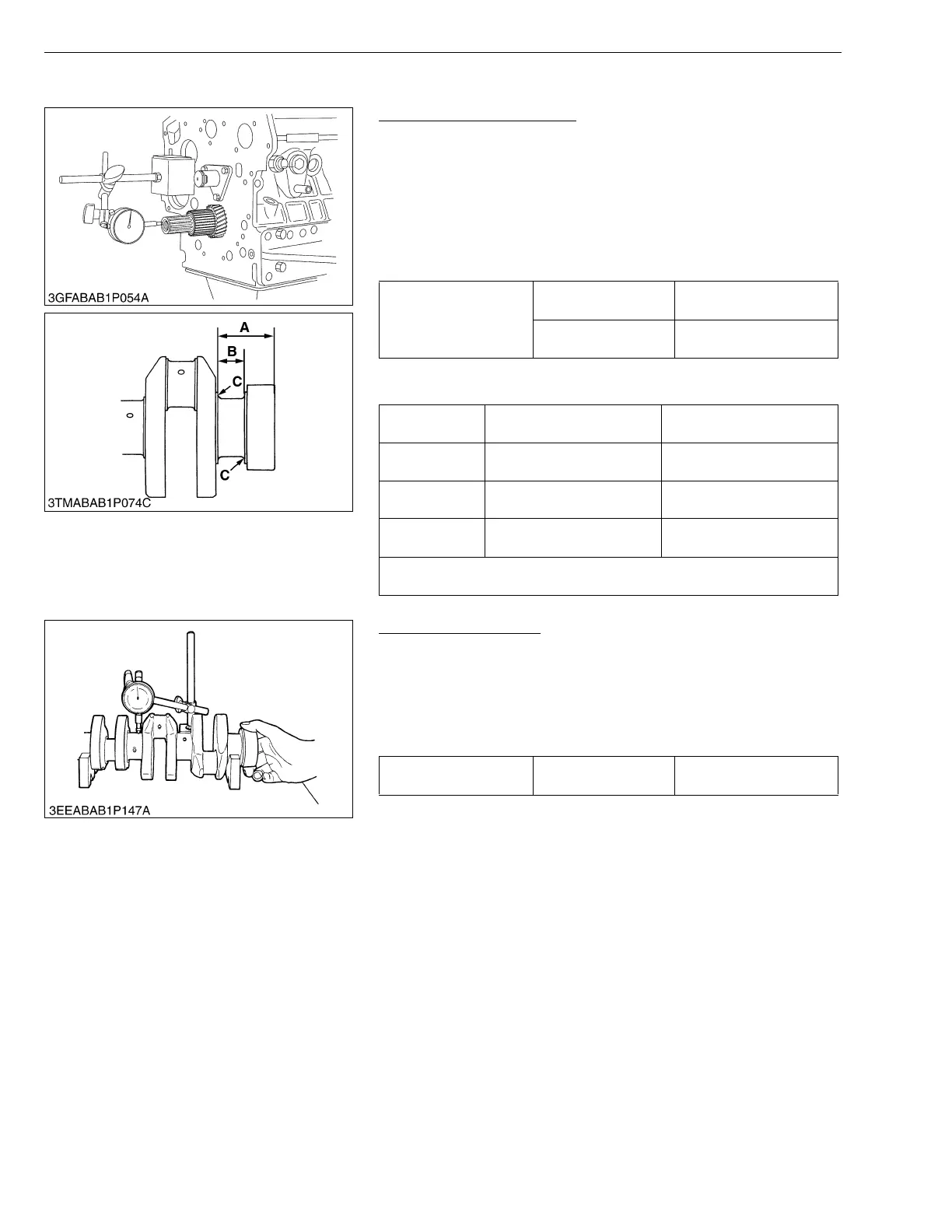

• Oversize dimensions of crankshaft journal

W10317070

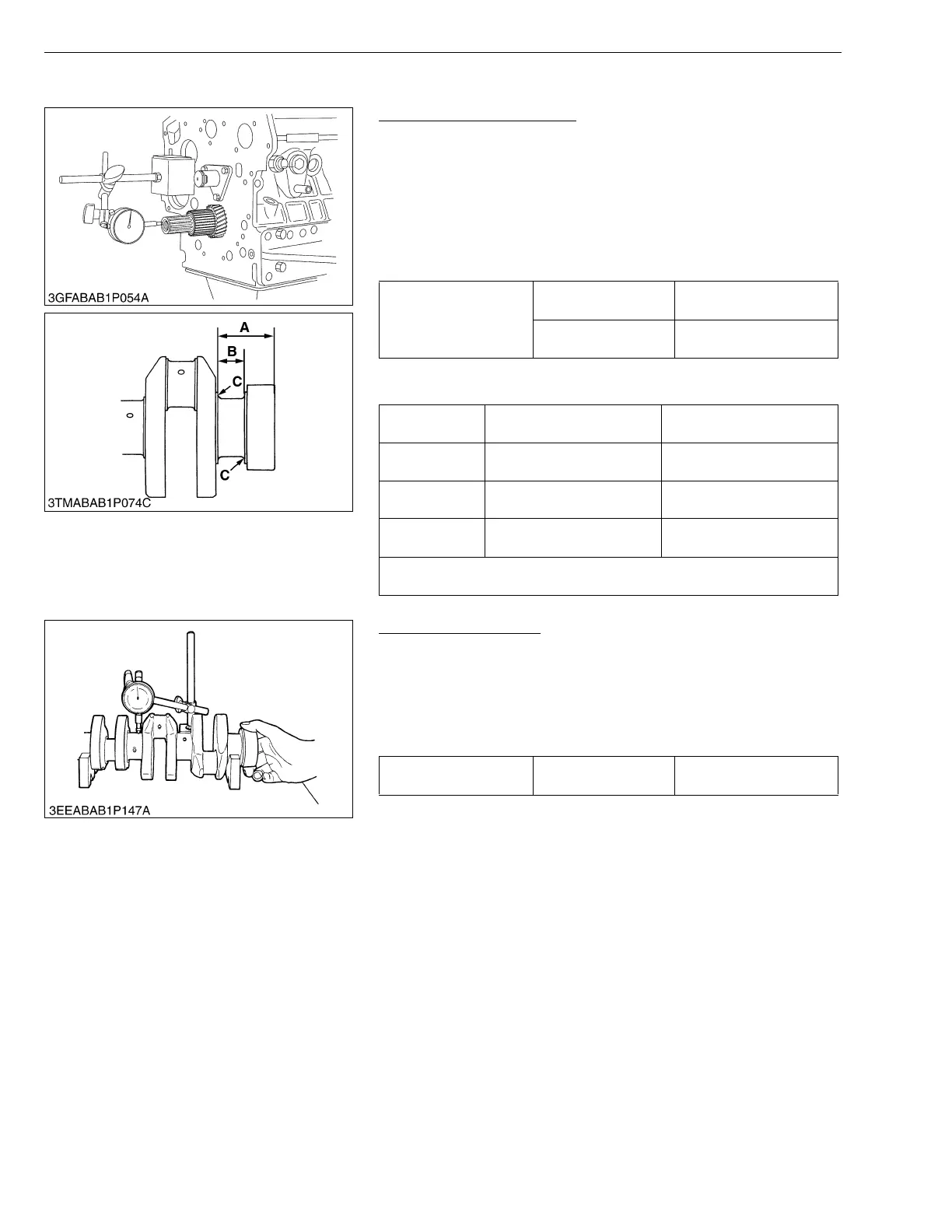

Crankshaft Alignment

1. Support the crankshaft with V blocks on the surface plate at both

end journals.

2. Set a dial indicator with its tip on the intermediate journal.

3. Measure the crankshaft alignment.

4. If the measurement exceeds the allowable limit, replace the

crankshaft.

W10330010

Crankshaft side

clearance

Factory spec.

0.15 to 0.31 mm

0.0059 to 0.0122 in.

Allowable limit

0.50 mm

0.0197 in.

Oversize

0.2 mm

0.008 in.

0.4 mm

0.016 in.

Dimension A

51.5 to 51.7 mm

2.028 to 2.035 in.

51.6 to 51.8 mm

2.031 to 2.039 in.

Dimension B

28.20 to 28.25 mm

1.1102 to 1.1122 in.

28.40 to 28.45 mm

1.1181 to 1.1201 in.

Dimension C

2.3 to 2.7 mm radius

0.091 to 0.106 in. radius

2.3 to 3.7 mm radius

0.091 to 0.106 in. radius

(0.8-S)

The crankshaft journal must be fine-finished to higher than ∇∇∇∇

Crankshaft alignment Allowable limit

0.02 mm

0.0008 in.

Loading...

Loading...