1-S53

F2880, F3680, RCK72-F36, RCK72R-F36, RCK60-F36, RCK60R-F36, WSM

ENGINE

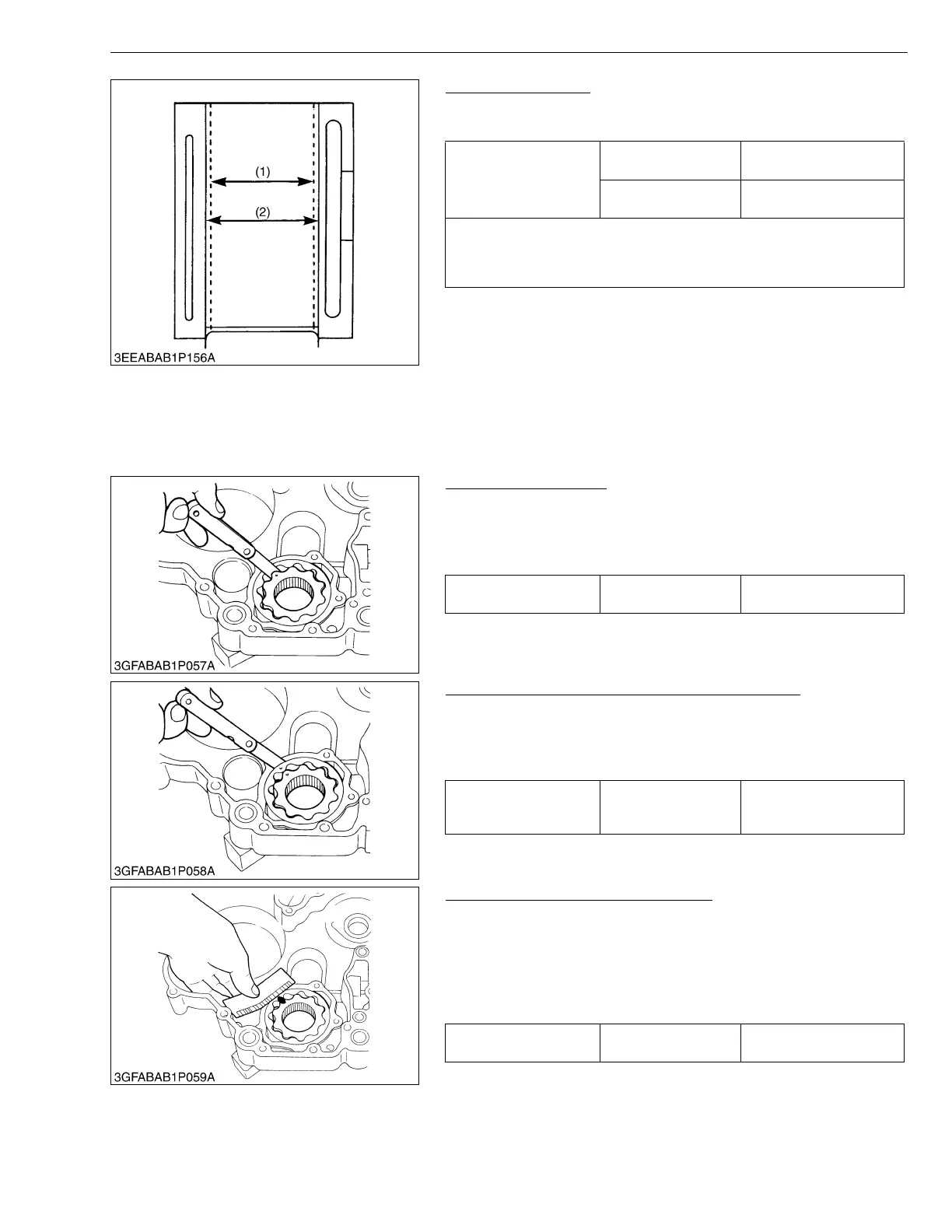

Correcting Cylinder

1. When the cylinder is worn beyond the allowable limit, bore and

hone it to the specified dimension.

2. Replace the piston and piston rings with oversize ones.

Oversize : 0.5 mm (0.0197 in.)

■

• When the oversize cylinder is worn beyond the allowable

limit, replace the cylinder block with a new one.

W10344480

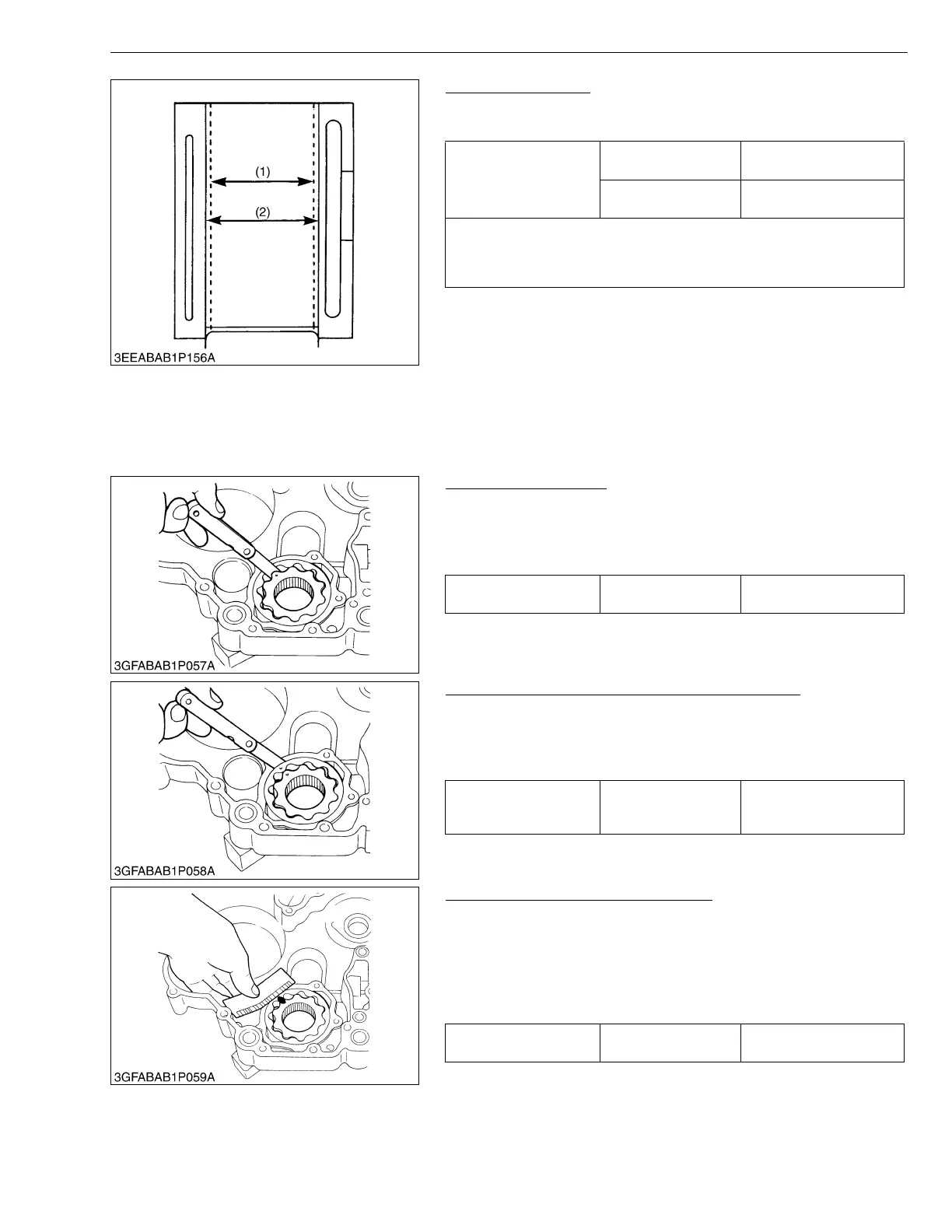

(6) Oil Pump

Rotor Lobe Clearance

1. Measure the clearance between lobes of the inner rotor and the

outer rotor with a feeler gauge.

2. If the clearance exceeds the factory specifications, replace the oil

pump rotor assembly.

W10355630

Clearance between Outer Rotor and Pump Body

1. Measure the clearance between the outer rotor and the pump

body with a feeler gauge.

2. If the clearance exceeds the factory specifications, replace the oil

pump rotor assembly.

W10356560

Clearance between Rotor and Cover

1. Put a strip of plastigage onto the rotor face with grease.

2. Install the cover and tighten the screws.

3. Remove the cover carefully, and measure the amount of the

flattening with the scale and get the clearance.

4. If the clearance exceeds the factory specifications, replace the oil

pump rotor assembly.

W10357320

Oversized cylinder liner

I.D.

Factory spec.

78.500 to 78.519 mm

3.0906 to 3.0913 in.

Allowable limit

78.65 mm

3.0965 in.

Finishing

Hone to 1.2 to 2.0 mm µR max.

∇∇∇

(0.000047 to 0.000079 in. µR max.)

(1) Cylinder I.D. (Before Correction) (2) Cylinder I.D. (Oversize)

Rotor lobe clearance Factory spec.

0.06 to 0.18 mm

0.0024 to 0.0071 in.

Clearance between

outer rotor and pump

body

Factory spec.

0.100 to 0.180 mm

0.0039 to 0.0071 in.

Clearance between rotor

and cover

Factory spec.

0.025 to 0.075 mm

0.0010 to 0.0030 in.

Loading...

Loading...