Maintenance work on the carrier

7.10 Vehicle brake

7 - 78 3 302 756 en Maintenance manual

GMK6400

16.11.2018

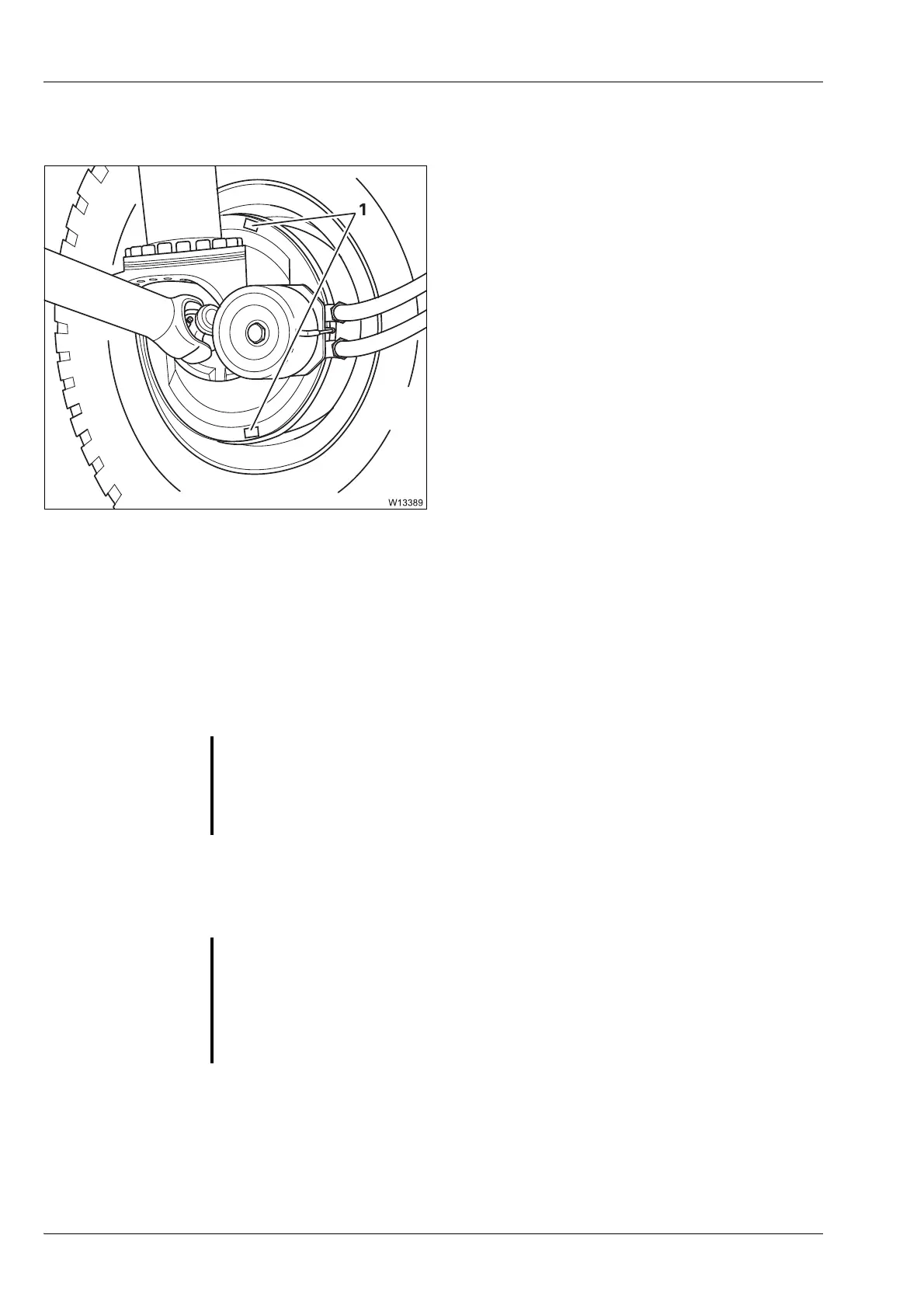

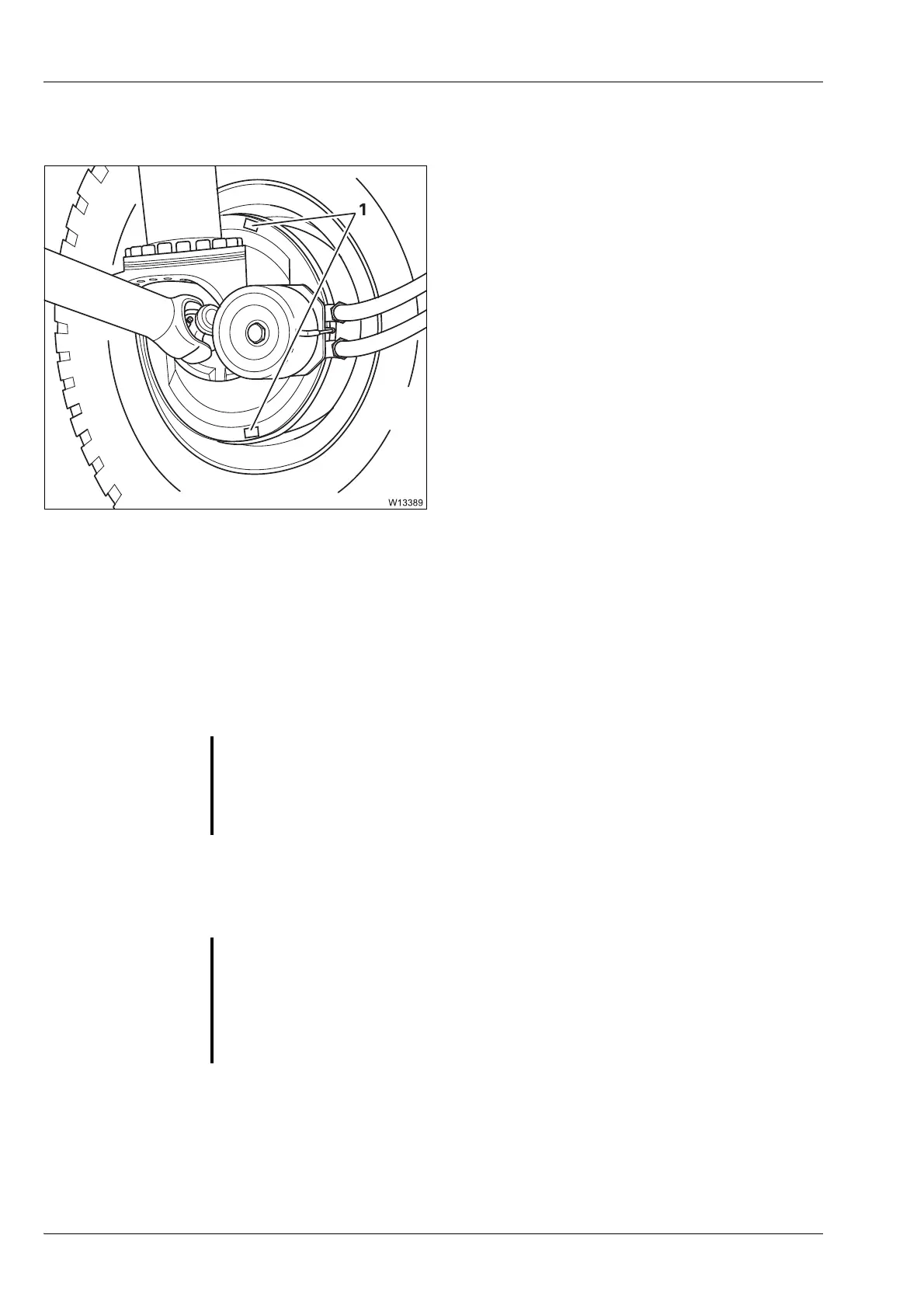

Checking • Check the thickness of the brake linings on all axle lines.

• Check the brake lining thickness from the

inside at the openings (1).

If the brake lining thickness has worn down to

the wear mark (stepped edges or grooves) or

the brake lining thickness has worn down to

only 6 mm (0.25 in):

• Have the brake lining replaced;

à Having repairs performed, p. 7 - 78.

• Close the openings using the covers.

Having repairs

performed

• Do not perform repair work on the vehicle brakes; à Safety instructions,

p. 7 - 77.

• All repair work on the vehicle brakes may only be performed by

Manitowoc Crane Care or an authorised GROVE dealer or an authorised

specialist workshop with specially trained repair crew.

• Make sure that only original spare parts are used; à Spare parts and tools,

p. 7 - 77.

Allow the brakes

to run in

New brake linings do not provide optimal braking and must therefore be run

in by periodic braking.

• Make sure that the new brake pads are sufficiently run in through test

drives before putting the truck crane into normal operation.

G

Risk of accidents due to uneven braking!

If the brake linings are only replaced on one side of the axle line then the

wheels have an uneven braking force.

Always have the brake linings replaced on both ends of the axle line.

S

Risk of damage to the brakes when running them in!

Constant or heavy braking at high speeds can overheat the brakes and

damage them.

The brakes must only be run in through periodic braking.

For this, braking must first be performed at low speed and then later at

medium speed.

Loading...

Loading...