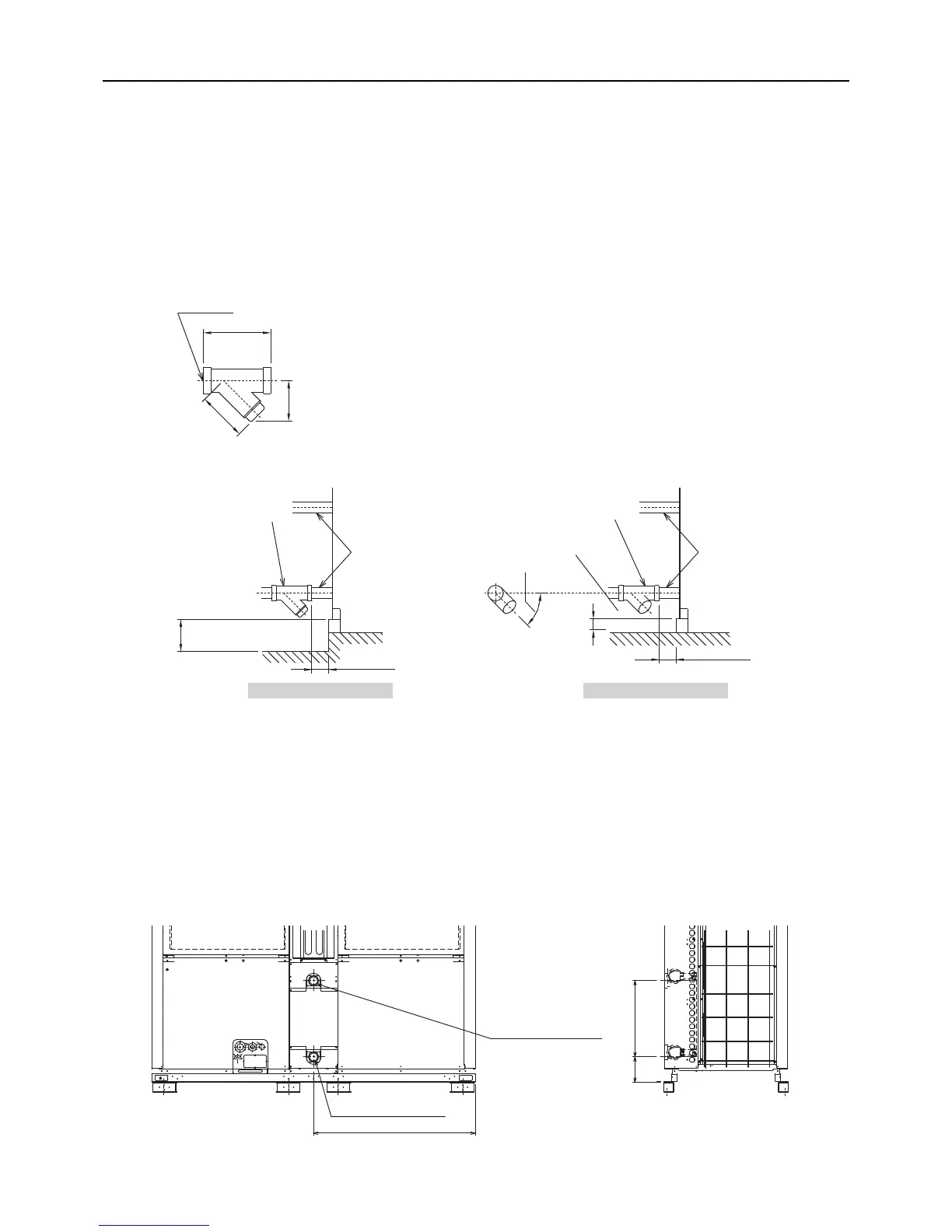

(1) Installing the strainer

Install the supplied strainer on the inlet water pipe near the unit to filter out suspended solids and prevent clogging or

corrosion of the heat exchanger.

Install the strainer in a way that allows for easy access for cleaning, and instruct the user to clean it regularly.

Operating the units with a clogged strainer may cause the units to make an abnormal stop.

Select a location to install a strainer, taking into consideration the installation angle, insulation thickness, and

maintenance space.

* The dimensions given below indicate the amount of space necessary when screwing in a Y-shaped strainer.

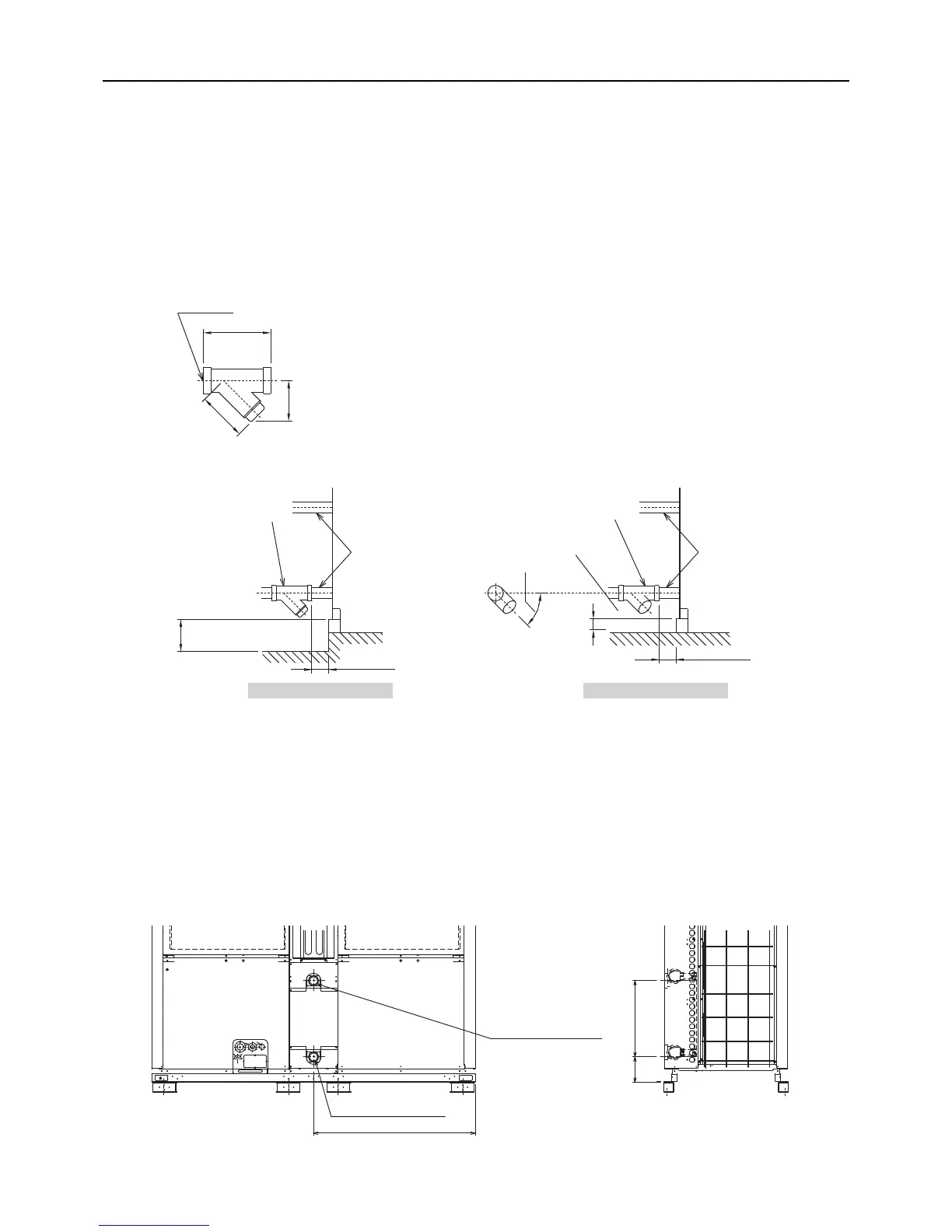

(2) Installing a flow switch

Install a flow switch that meets the following specifications on the water pipe.

Connect the flow switch to the flow switch contact on the unit.

Minimum flow rate= 7.5 m³/h (125 L/min)

Unit usage range (water flow rate): 7.5 - 15.0 m³/h

Rc1 1/2

160

11

5

100

Y-shaped strainer

(supplied)

Pipes

(field-supplied)

Min. 110

Y-shaped strainer

maintenance access space

153

Sample installation 1 Sample installation 2

Min. 110

* Min. 43

Max. 25º

Y-shaped strainer

maintenance access space

Y-shaped strainer

(supplied)

Pipes (field-supplied)

<Unit: mm>

Loading...

Loading...