PARAMETERS

134

Pr. 73 "0-5V/0-10V selection"

Pr. 79 "operation mode selection"

Pr. 180 to Pr. 183 (input

terminal function selection)

Pr. 191 to Pr. 192 (output

terminal function selection)

Pr. 902 to Pr. 905 (frequency

setting voltage (current)

biases and

gains)

Related parameters

4.2.37 PID control (Pr. 128 to Pr. 134)

Pr. 128 "PID action selection"

Pr. 129 "PID proportional band"

Pr. 130 "PID integral time"

Pr. 131 "upper limit"

Pr. 132 "lower limit"

Pr. 133 "PID action set point for PU operation"

Pr. 134 "PID differential time"

The inverter can be used to exercise process control, e.g. flow rate, air volume or

pressure.

!

!!

!

The voltage input signal (0 to

±

5V or 0 to

±

10V) or Pr. 133 setting is used as a set

point and the 4 to 20mA DC current input signal used as a feedback value to

constitute a feedback system for PID control.

Parameter

Number

Factory

Setting

Setting Range Remarks

128 0 0, 20, 21

129 100% 0.1 to 1000%, 9999 9999: No proportional control

130 1s 0.1 to 3600s, 9999 9999: No integral control

131 9999 0 to 100%, 9999 9999: Function invalid

132 9999 0 to 100%, 9999 9999: Function invalid

133 0% 0 to 100%

134 9999 0.01 to 10.00s, 9999 9999: No differential control

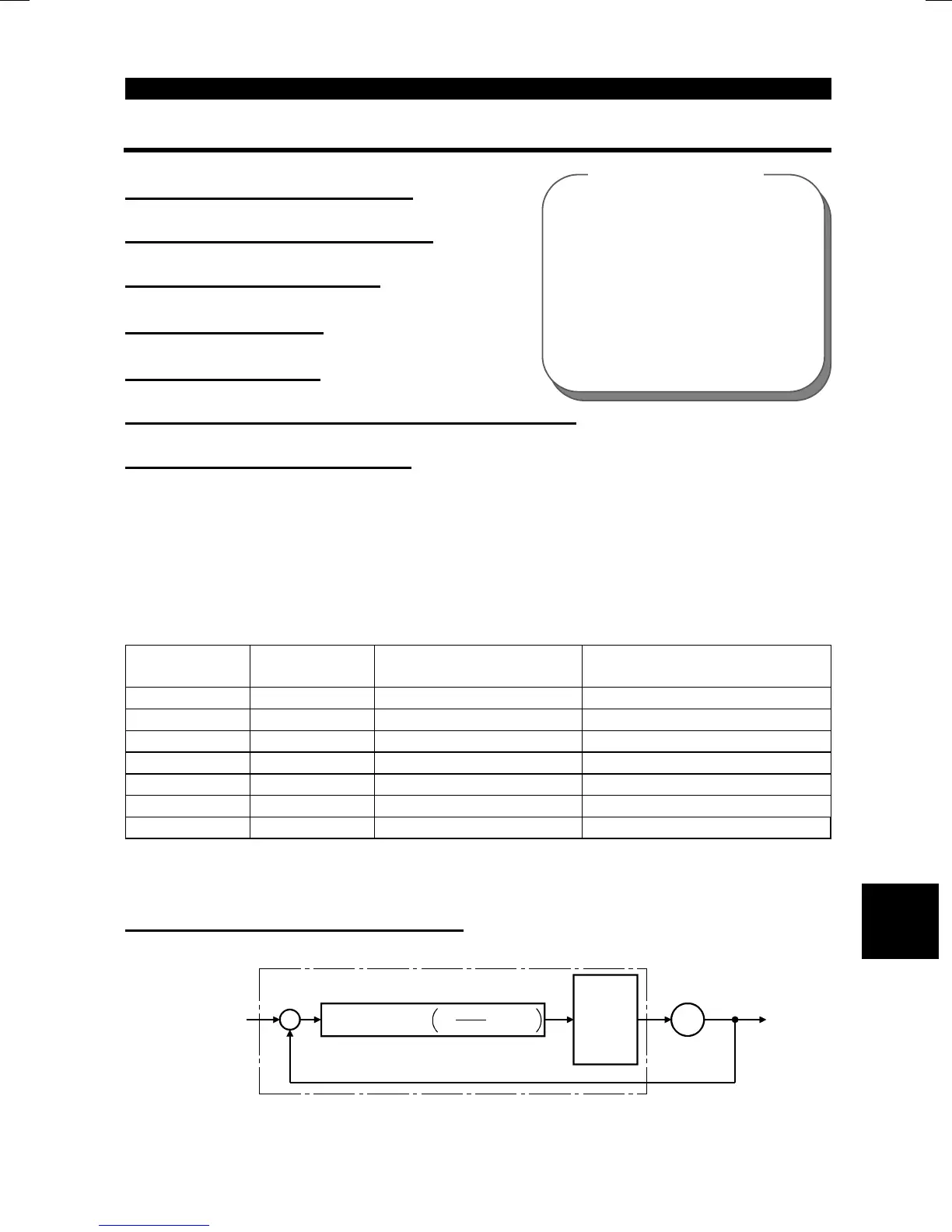

<Setting>

(

1

)

Basic PID control configuration

+

-

(x)

(y)

Deviation

Process value

(fi)

Manipulated variable

Motor

IM

y

Set point

(U)

Ti

×

S

1

Kp

+ +

PID operation

Td

×

S

Drive

circuit

Kp : Proportional constant

Ti : Integral time

S : Operator

Td : Differential time

1

Inverter

4

Loading...

Loading...