4.14

ELECTRONIC FUEL INJECTION

9923523 - 2012 RANGER RZR 570 Service Manual

© Copyright 2011 Polaris Sales Inc.

CRANKSHAFT POSITION SENSOR (CPS)

Operation Overview

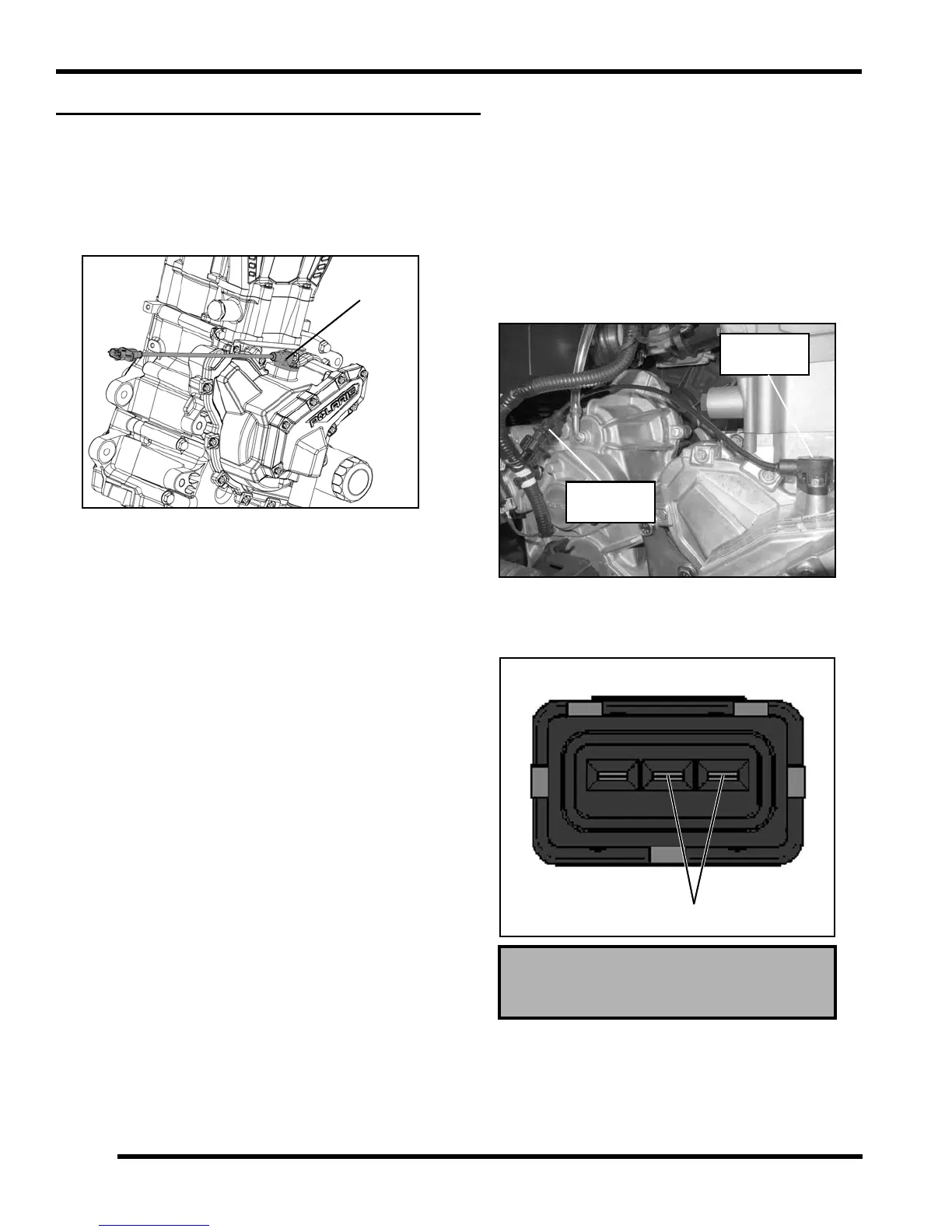

Mounted on top of the stator cover, the crankshaft position

sensor is es sential to engine op eration, co nstantly

monitoring the rotational speed (RPM) and position of the

crankshaft.

A ferromagnetic 35-tooth encoder ring with a missing tooth

is bu

ilt onto the flywheel. The inductive speed sensor is

mounted 1.0 ± 0.26 mm (0.059 ± 0.010 in.) away from the

encoder rin g. During ro tation, a n AC pu lse is cr eated

within the se nsor for each p assing to oth. Th e ECU

calculates en gine speed from the tim e interval be tween

the consecutive pulses.

The encoder ring missing tooth creates an “interrupt” input

sig

nal, corresponding to specific crankshaft position. This

signal serves as a r eference for the con trol of ig nition

timing by the ECU. Synch ronization o f the CPS a nd

crankshaft po sition t akes place d uring the first two

revolutions each time the engine is started. This sensor

must be properly connected at all times. If the sensor fails

or becomes disconnected for any reason, the engine will

stop running.

CPS Test

The CPS is a sealed, non-serviceable assembly. If fault

code diagnosis indicates a problem with this sensor, test

as follows:

1. The CPS is accessible through the r ight-hand r ear

wh

eel well area.

2. Disconnect CPS harness connector.

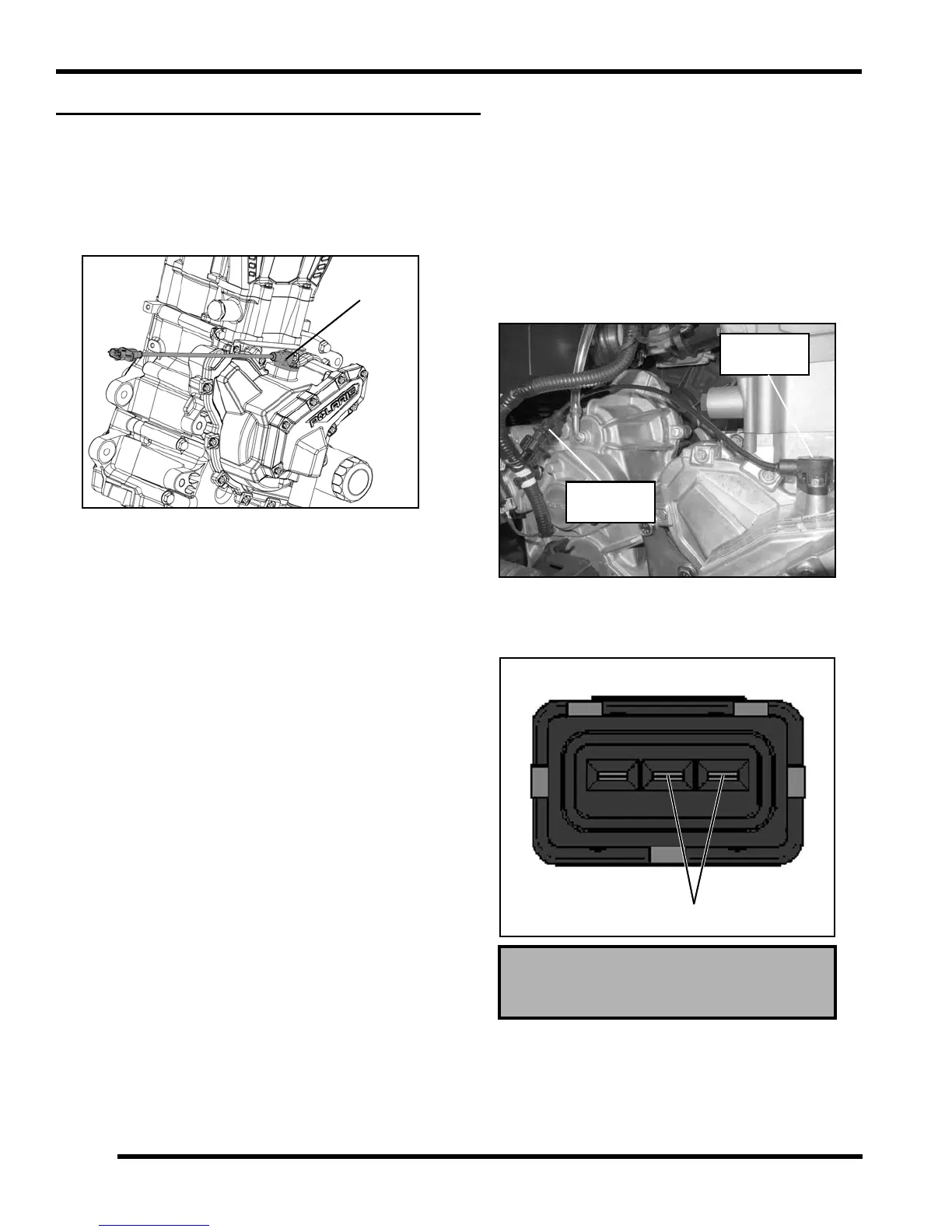

3. Connect an ohmmeter between the CPS pin terminals

sh

own below. A resistance value of 1000 Ohm ± 10%

at room temperature should be obtained.

CPS Resistance Specification:

1000 Ohms ± 10%

Loading...

Loading...