6. Cylinder Head/Cylinder/Piston

6-2

Maintenance Information

Precautions in Operation

y The inspection and maintenance of the cylinder head, cylinder and piston can be carried as engine

mounted on the body.

y It should clean the engine to prevent dirt from entering into cylinder and crankcase before removal.

y Remove all washes from the interfaces of cylinder head, cylinder and crankcase.

y Be careful do not damage cylinder head, cylinder and piston when removing.

y Inspect the removed & cleaned parts thoroughly, and apply with oil onto the rotation surfaces before

installation.

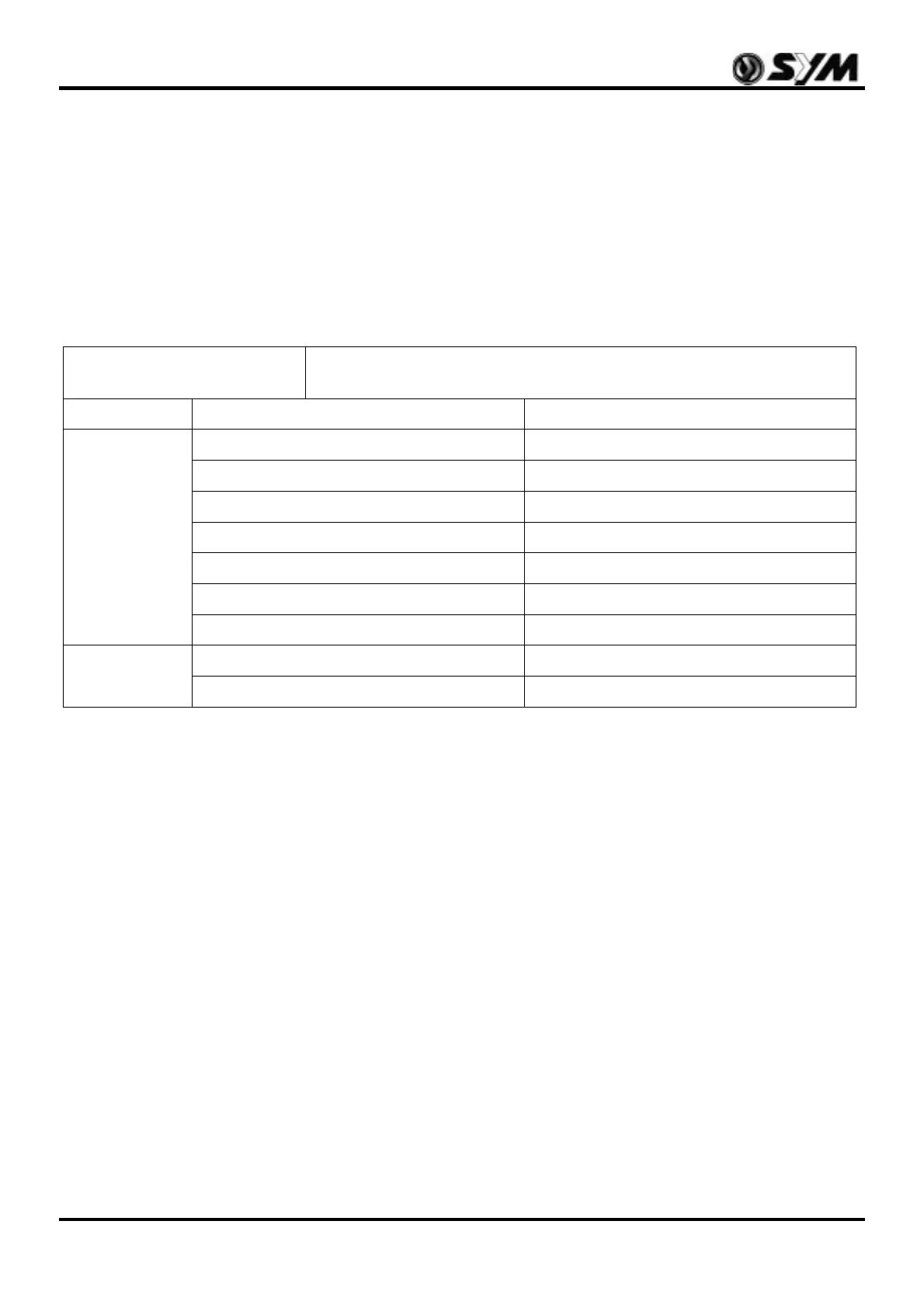

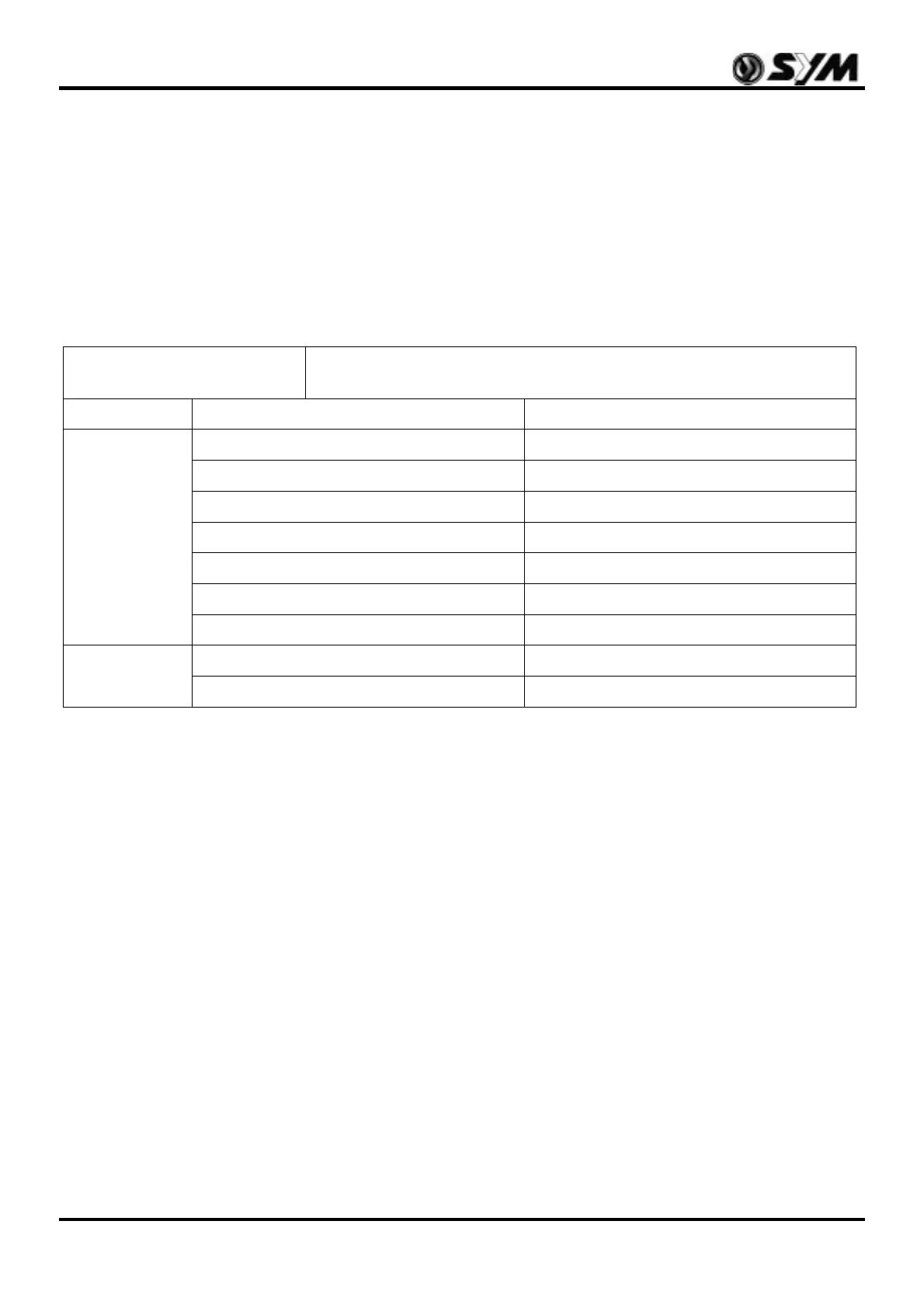

Specification

Item Standard value (mm)

Cylinder head Deformation -

Piston OD 38.955~38.970

Clearance between cylinder and piston 0.030~0.050

Piston pin hole 12.002~12.008

Piston pin OD 11.994~12.000

Clearance between piston and piston

0.002~0.014

Piston ring end gap 0.100~0.250

Piston

ID of connecting rod small end 17.005~17.017

ID 39.000~39.015 Cylinder

Deformation -

ID: inner diameter OD: outer diameter

Tighten torque value

Cylinder head 1.6~2.0kgf-m

Spark plug 1.1~1.7kgf-m

Exhaust pipe connection nut 0.8~1.2kgf-m

Exhaust muffler mounting bolt 2.4~3.0kgf-m

Troubleshooting

Compression Pressure Too Low/Difficult

To Start/Rough Idling

1. Cylinder head gasket leaking

2. Spark plug not tighten enough

3. Worn, seized or crack piston ring

4. Damaged, worn cylinder or piston

5. Poor reed

Compression Pressure Too

High/Overheat/Knock

1. Too much carbon deposit built up in

combustion chamber

Piston Noise

1. Cylinder and piston worn out

2. Piston pin or piston pin hole worn out

3. Connecting rod small end bearing worn out

Piston Ring Noise

1. Worn, seized or crack piston ring

2. Cylinder worn out or damaged

Loading...

Loading...