DISASSEMBLY AND ASSEMBLY

ATTACHMENTS

5

4

ATTACHMENTS 4G0AX001

Removing the hoe attachment

Important:

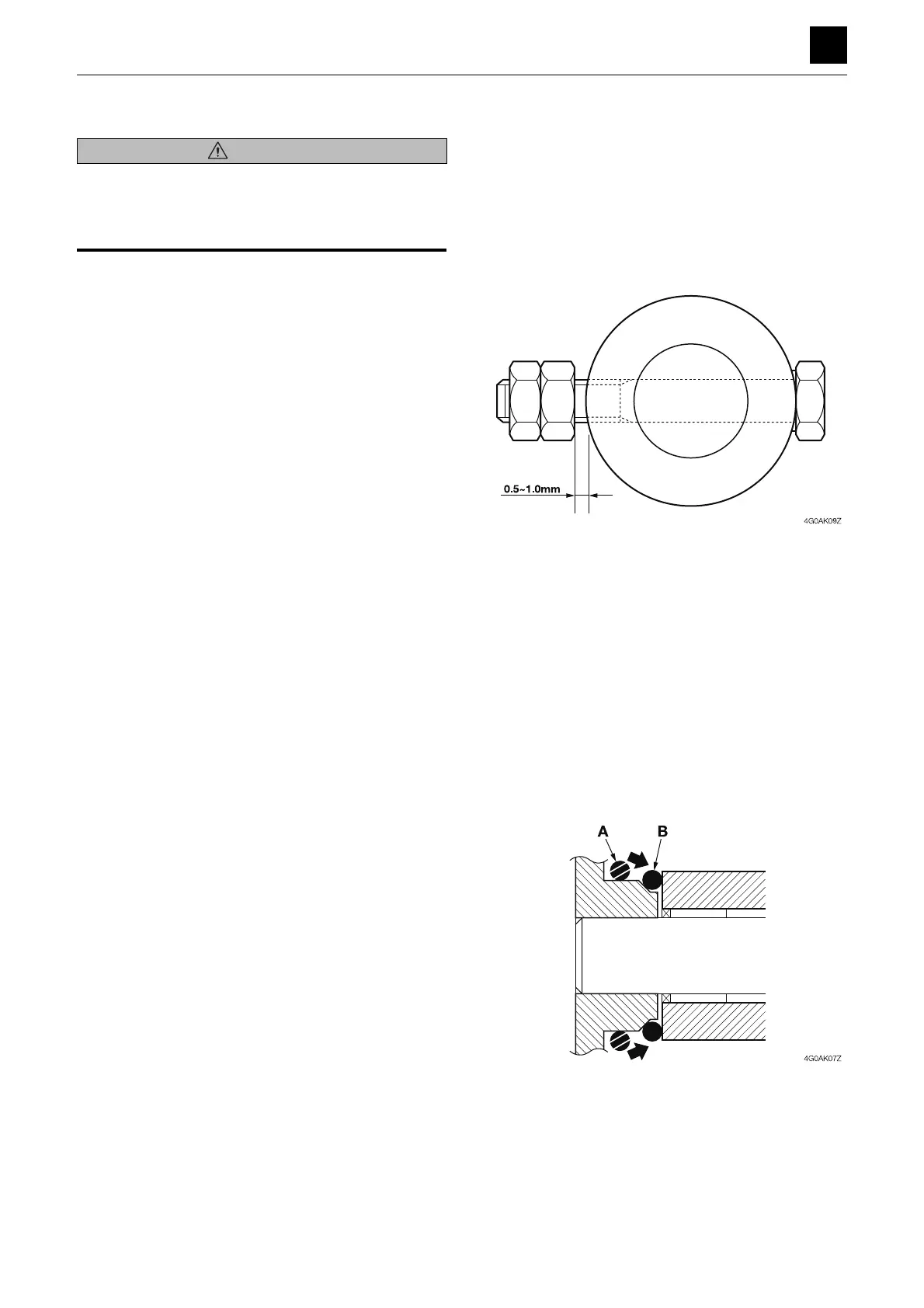

• When tightening the lock bolt with a double nut, allow a

clearance of 0.5 mm to 1.0 mm (0.0197 in. to 0.0394

in.) between the nut and the lock collar.

• Adjust the clearance for the pin connector to a width of

between 0.2 mm to 0.5 mm (0.0079 in. to 0.0197 in.)

using a shim.

• Be sure to bleed the air from the cylinder before starting

operation for the first time after reassembling hydraulic

devices such as the hydraulic cylinder or hydraulic pip-

ing.

• Grease the pins using lithium grease EP-2 supplied

from the grease nipples.

The numbers in parentheses, (), listed after the names of

parts throughout this document are used to refer to the

same parts as the numbers listed in the construction di-

agram and parts lists.

Removing the bucket

1. Orient the back of the bucket downward, and lower

the bucket all the way down to the ground.

2. Take out the bolts, and remove the pins.

3. Remove the bucket.

Installing the bucket

To install, follow the same procedures as for removal but

in the reverse order.

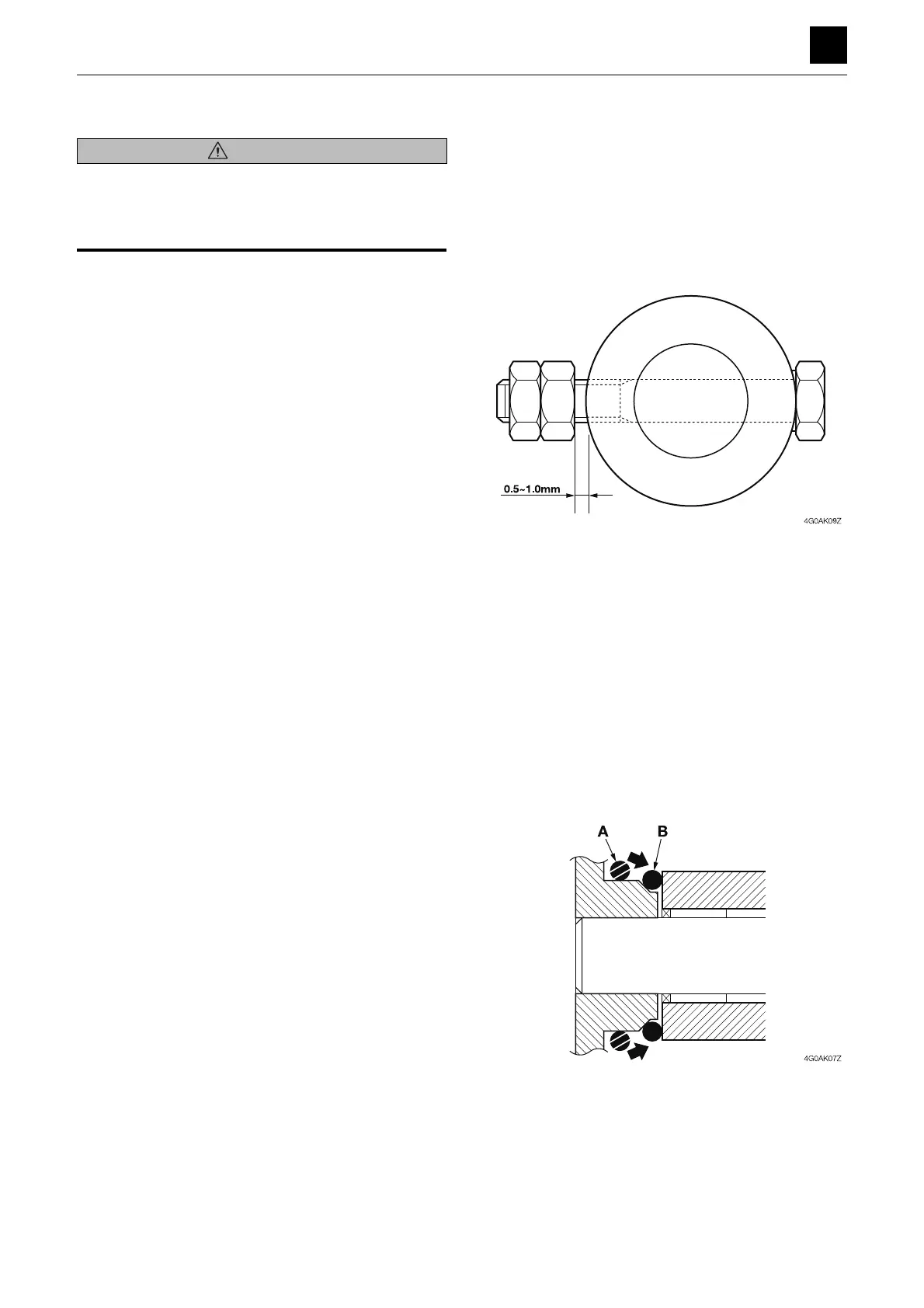

• Before starting to attach the bucket, place the O-ring

in the temporary placement position “A” in the outer

circumference of the bucket bushing, and move it to

the specified position “B” once attachment is complet-

ed.

WARNING

• Be sure to release any residual pressure in the piping

before disconnecting the hydraulic hose.

• Do not attempt to insert any fingers into the hole when

adjusting the pin hole position.

Loading...

Loading...