DISASSEMBLY AND ASSEMBLY

SWIVEL JOINT

2

4

SWIVEL JOINT 4O0AX00

DISASSEMBLY AND ASSEMBLY

General Cautions

• Carry out disassembly and assembly operations in

a clean place and provide clean containers to place

the disassembled parts in.

• Before disassembly, clean around the ports and

remove the paint from each joint using a wire

brush.

• Clean all disassembled parts in cleaning solvent.

Use a lint free cloth, or air dry the parts.

• Make match marks on each part so that they will be

assembled in the same positions when assembled.

• Replace all seals with new ones each time the

hydraulic units is disassembled.

• Check each part to make sure there is no abnormal

wear or seizing and use sandpaper, etc. to remove

any burrs, sharp edges, etc.

• Do not turn adjusting screws if not required.

• Apply hydraulic oil to sliding surfaces and apply a

thin coating of grease to seals when assembling

them.

The following describes the disassembly procedure.

For assembly, follow the disassembly procedure in

the reverse order.

Disassembly

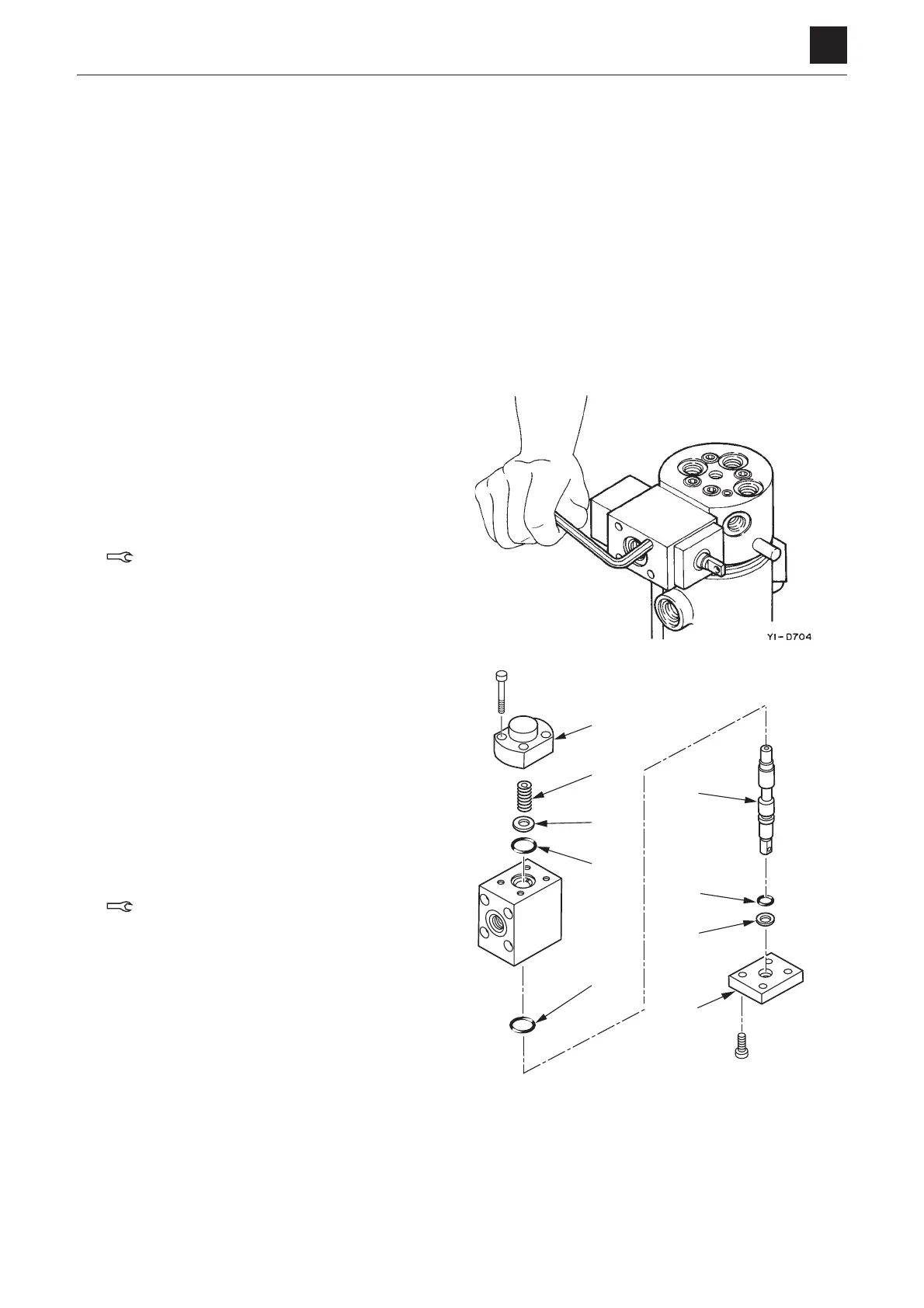

Selector

1. Remove the cap screw, and take off the selector

and O-ring from the shaft of the swivel joint.

Cap Screw: 6.9 N·m(5.1 ft-lb.)

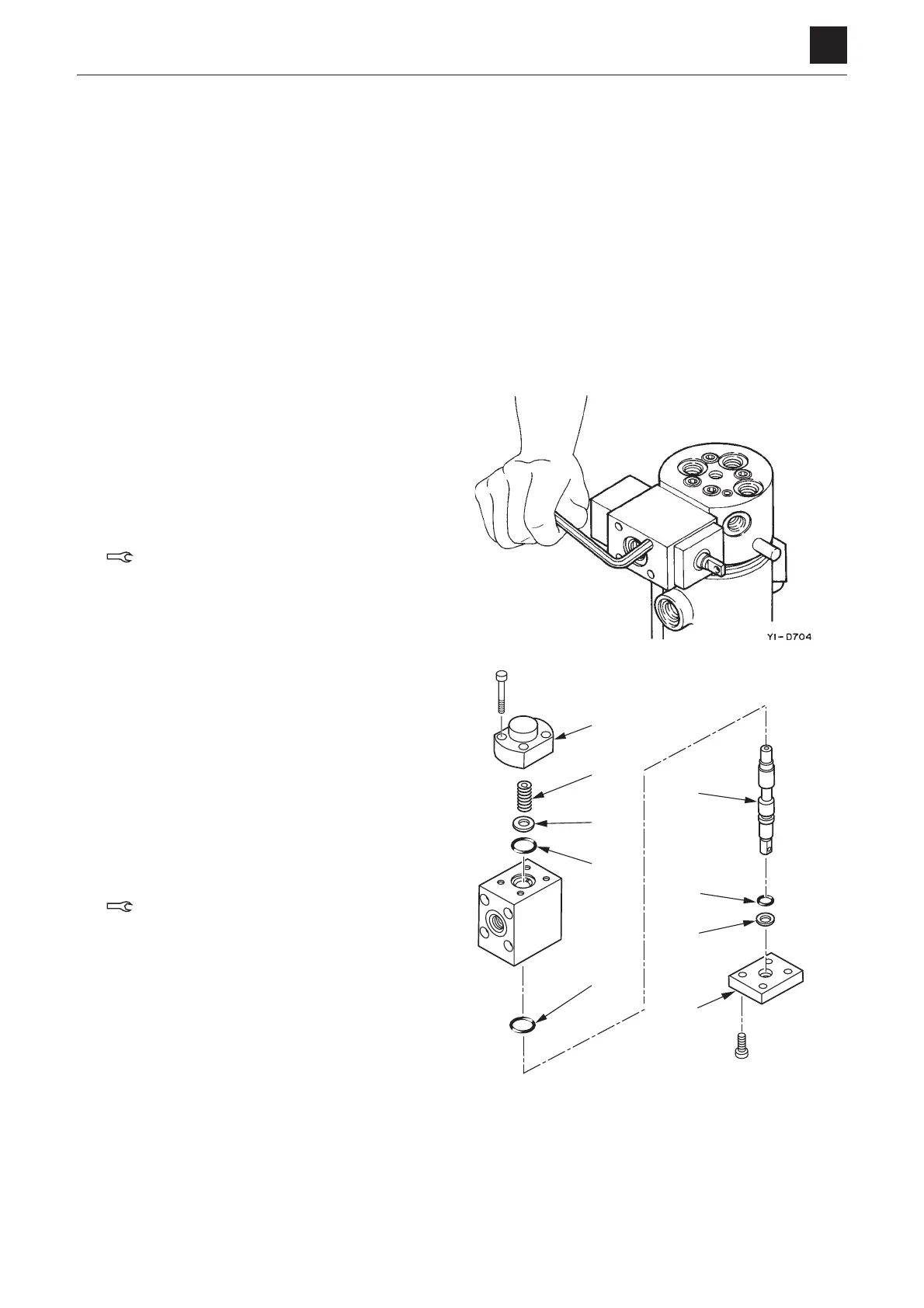

2. Loosen the cap screw and remove the cover (1).

Then remove the spring (2) and washer (3) from

the spool (4).

3. Remove the spool (4) from the body.

4. Loosen the cap screw and remove the cover (5),

backup ring (6) and O-ring (7).

• When assembling, confirm that the spool moves

smoothly.

Cap Screw: 6.9 N·m(5.1 ft-lb.)

5. Remove the O-ring (8) from the body assembly.

Loading...

Loading...