15

4

CYLINDERS

DISASSEMBLY AND ASSEMBLY

4L0AX00CYLINDERS

Inspection after assembly

No load operation test

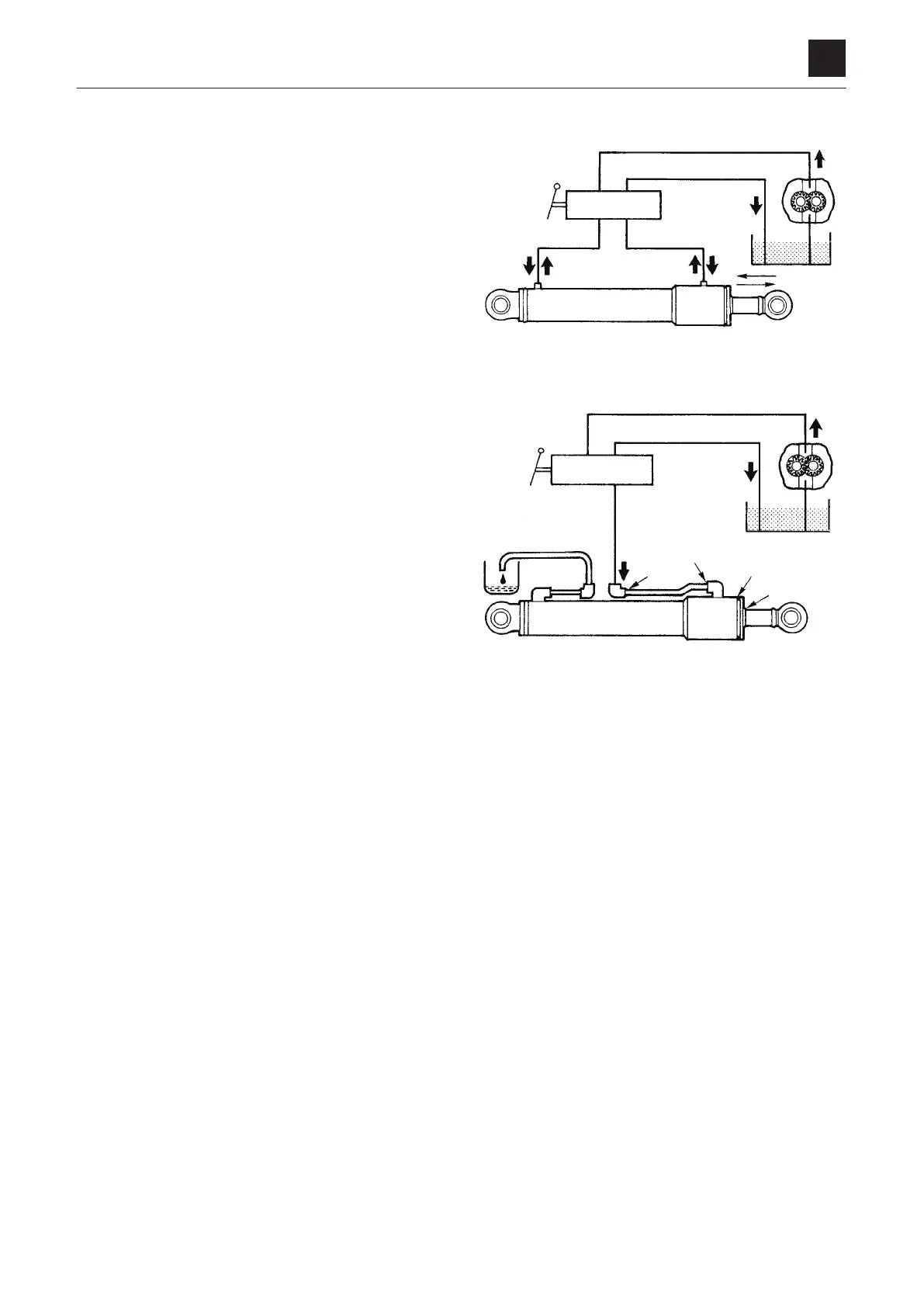

1. Place the cylinder in a horizontal position with no load.

2. Apply gentle pressure alternately to the ports at both

ends, operating the piston rod 5 or 6 times.

3. Make sure there is no abnormality in the operating con-

dition.

Leak test

External leak

1. Apply test pressure for 3 minutes each to the retraction

sideandtheextensionside.

2.Makesuretherearenoabnormalitiessuchasexternal

leakage or permanent deformation, etc. in the rod seal,

the rod cover mount, or in any welded portion.

Internal leak

1.Disconnecttheextensionsidehose.

2. Apply test pressure to the retraction side for 3 min-

utes.

3. Measure the amount of oil that has leaked from the

extensionside.

• Theamountofleakageshouldbe1mL(0.034.oz)

/3 min or less.

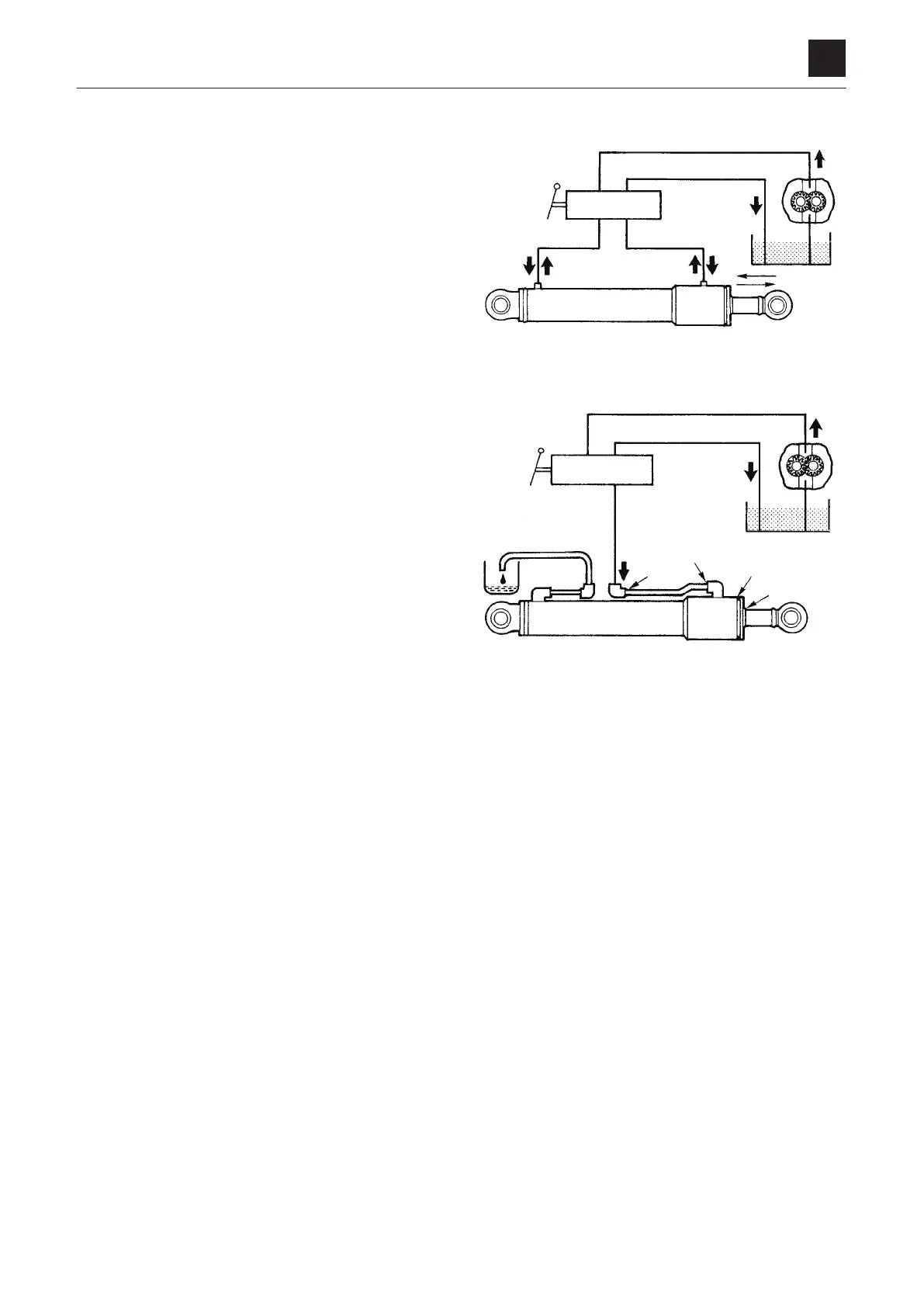

Bleeding air from the hydraulic cylinder

Bleed the air out of the cylinder when the cylinder is re-

moved or when the hydraulic piping, etc. is disconnected.

1.Starttheengineandletitidleforapproximately5min-

utes.

2.Withtheenginerunningatslowspeed,extendandre-

tract the cylinder 4 or 5 times.

• Movethepistonrodtoaposition100mm(3.94in.)

before the end of the stroke, being careful not to

relieve air.

3. With the engine at top speed, repeat the operation in

(2),thenwiththeenginerunningatslowspeed,move

the piston rod to the stroke end to relieve air.

Loading...

Loading...