. . . . .

SAFETY

Warnings

TP04300 Series Interface & Applications Manual 1-3

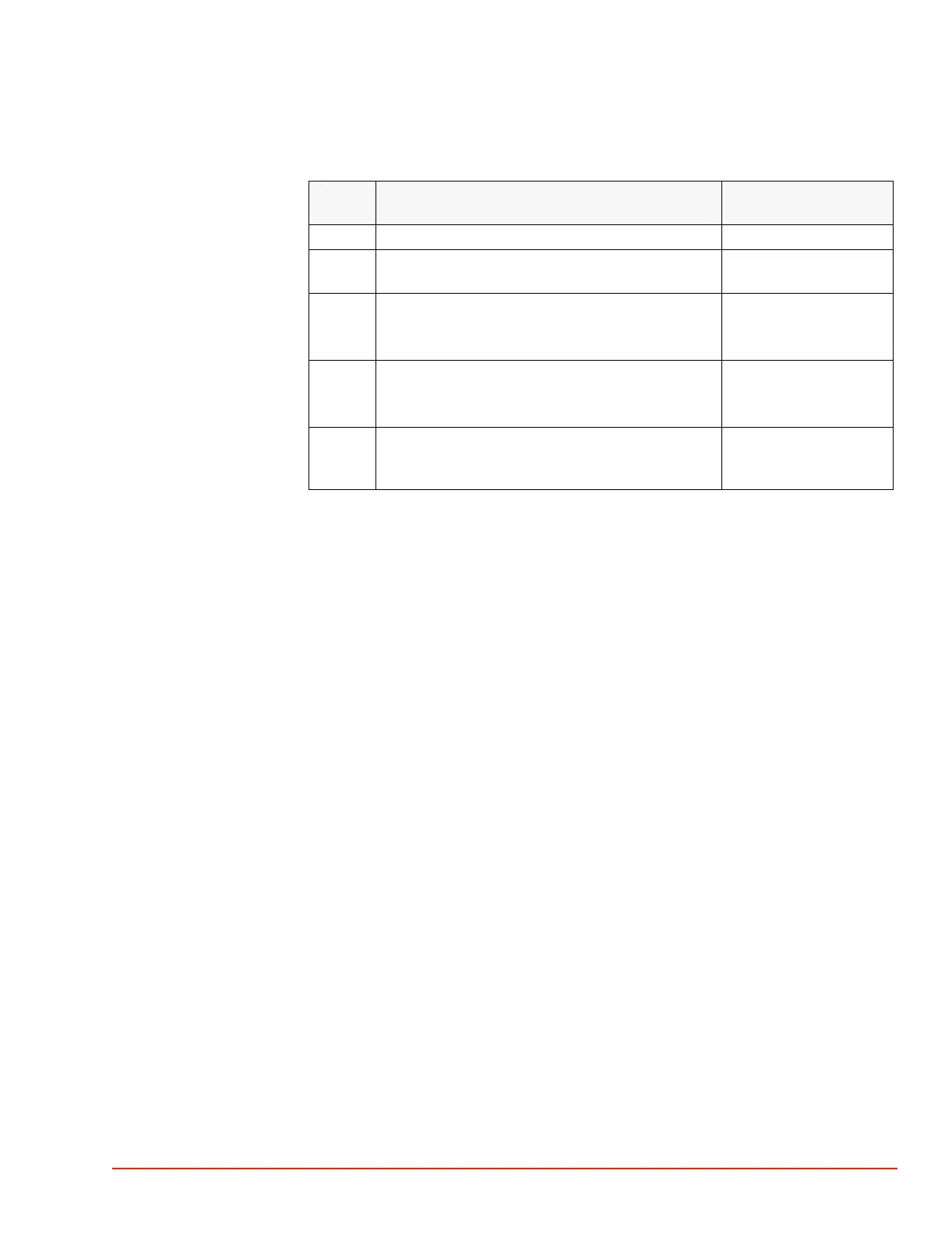

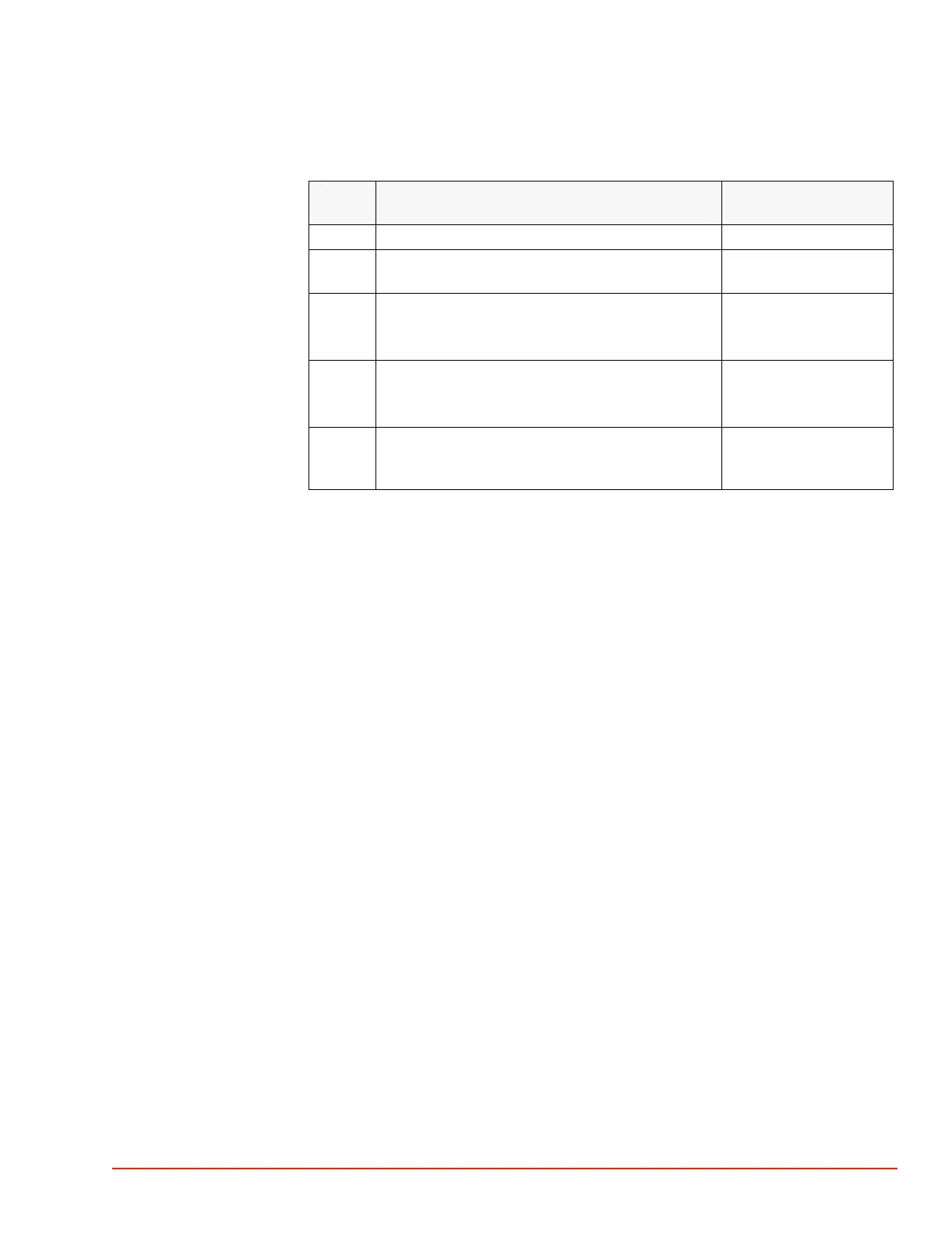

WARNING 7: Per SEMI S2-93A, energized electrical work (“Hot Work”) is specified by

Type as follows:

WARNING 8: Where equipment must be fully de-energized (electrically “cold”) to allow safe

entry into system, the following Lockout/Tagout procedure is required per OSHA 29 CFR

1910: a) For devices with a power cord which “unplugs” from a service receptacle, the end

user must supply and tag a Plug lockout shell which completely encloses the plug and prevents

accidental reconnection; b) for devices hardwired to the electrical supply, the end user must

install and tag a power disconnect switch with a lock out position, or install and tag a circuit

breaker with a lock out position, to prevent accidental reconnection.

WARNING 9: To de-energize the System for safe replacement of a module, turn off the ac

power (cease operations and power down), then turn off the System’s air pressure supply, then

bleed all air from System by turning on ac power just long enough to exhaust all air from

System. Now disconnect both the main power supply cord and disconnect the air supply line

from air supply port fitting on the rear frame module. The only stored energy remaining in the

System will then be that within some electrical capacitors. One large capacitor is near the

System’s air-chiller compressor. Other large capacitors are in the System’s electrical power

supplies.

WARNING 10: If service of the Air Chiller Module is required, only a licensed (and/or EPA

Certified) refrigeration service person, authorized by the Temptronic Corporation, is qualified

to perform any charging or handling of the refrigerants in the System.

WARNING 11: Under no circumstances (leak testing or any other purpose) is the Air Chiller

Module to be charged with any gas at a pressure above 150 psig (10.34 bar).

WARNING 12: The Air Chiller Module acts as a counterbalance for the Thermal Head

Assembly. Before removing the Air Chiller Module, make sure the horizontal arm is down on

the vertical C-arm at its lower limit, and the thermal head is in next to the horizontal arm and

stowed toward the rear of the machine. Use appropriate weight lifting equipment when

removing/servicing the Air Chiller module.

WARNING 13: Two persons are required when removing (or installing) the thermal head

assembly at the end of the horizontal arm. One person must lift the thermal head assembly by

the head’s front handles, using both hands, while the other person loosens (or tightens) the

pivot lock.

TYPE DESCRIPTION (per SEMI S2-93A) EXPOSURE

THRESHOLD

1 Fully de-energized (electrically “cold.”) n.a.

2 Live circuits, covered or insulated. Work performed

at remote location to preclude accidental shock.

n.a.

3 Live circuits exposed.

Accidental contact is possible.

<= 30v RMS, 42.2v peak,

240 volt-amps, and 20

Joules

4 Live circuits exposed.

Accidental contact is possible.

> 30v RMS, 42.2v peak,

240 volt-amps, and 20

Joules

5 Energized. Measurements & adjustments require

physical entry, or equipment configuration does not

allow use of clamp-on probes.

n.a.

Loading...

Loading...