5

ROUTINE MAINTENANCE

Drain Moisture from Pneumatics Filter Elements

5-6 TP04300 Series Interface & Applications Manual

Drain Moisture from Pneumatics Filter Elements

Introduction At least once a week (daily if system is used during multiple shifts), remove the front panel and

follow the procedure below to drain moisture from (bleed) the filter elements.

Failure to drain moisture can result in system freeze up, which restricts air flow, and can render

the system inoperable. Although the time required to defrost the system will vary, defrosting

can take hours (see Defrosting Procedure Screen, page 3-30).

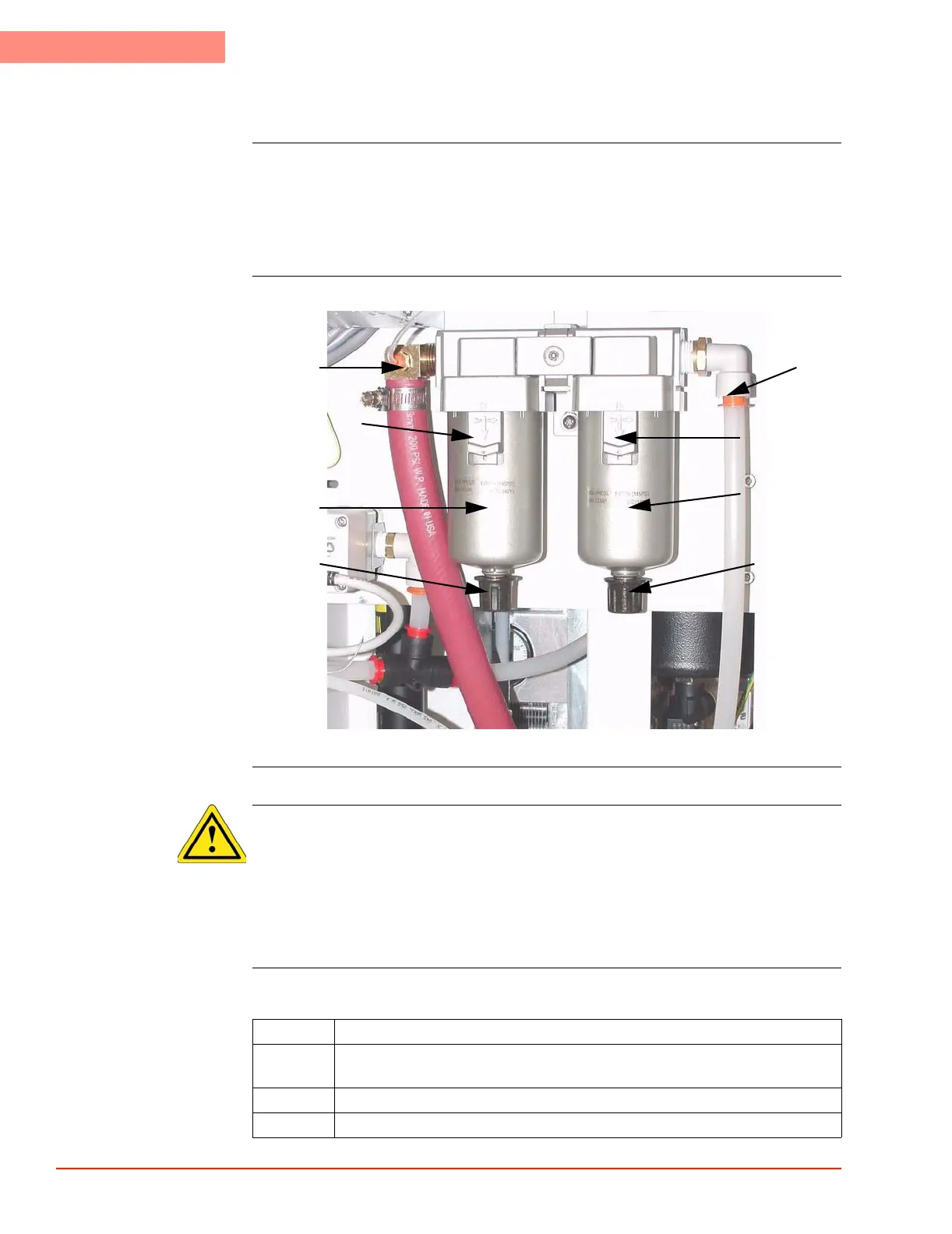

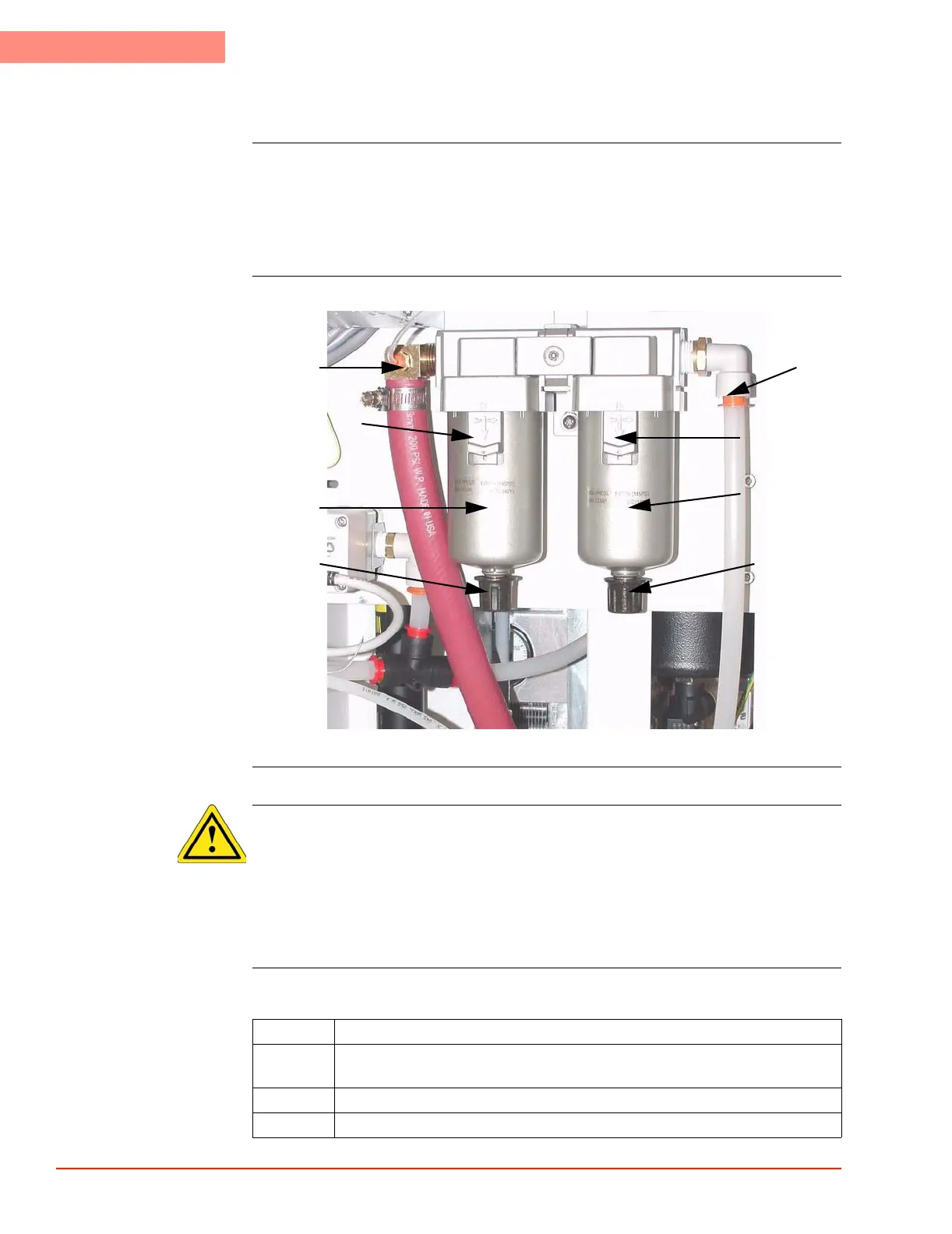

Particle and

Coalescing Filter

detailed

MVC-140F.JPG

Procedure

WARNING

WARNING 6: To prevent high-pressure ejection of condensate (which may or may not

contain injurious substances) when draining moisture from the air filter elements, first turn off

the system's air pressure supply, second bleed all air from the system by turning on ac power to

the TP04300 just long enough to exhaust air in the system, third disconnect the supply line

from the air supply port fitting located on the rear panel of the frame module.

Air In

Filter Guard

Snap Lock

Particle

Filter

Drain

Spigot

Air

Out

Filter Guard

Snap Lock

Coalescing

Filter

Drain

Spigot

Step Action

1 Remove front panel to access particle/coalescing filters, and/or, remove right

side panel to access post air filter

2 Disconnect air supply and bleed air pressure as given in Warning 6 above

3 Place container below particle filter drain spigot.

Loading...

Loading...