4

REMOTE INTERFACES

Syntax Overview

4-6 TP04300 Series Interface & Applications Manual

Section C:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Syntax

Syntax Overview

In Version 3, for both GPIB (IEEE-488.2) and Serial (RS-232C):

• All message strings to and from the TP04300A consist of ASCII characters.

• Numerical arguments are always sent/received in decimal format as a string of ASCII

characters.

• Some numerical arguments consist of a series of binary flags. They are sent as a decimal

number equal to the sum of the binary weights of each flag bit that is a “one.”

• Commands with arguments must have a space between the command and the argument.

• Serial (RS-232C) program messages (strings) must be terminated with a line feed. GPIB

program messages (strings) may be terminated with a line feed, by setting the EOI line, or

both.

• In GPIB mode, response messages from the TP04300A are terminated with a line feed

character with the EOI line set. In Serial mode, response messages are terminated with a

carriage return followed by a line feed.

• Program message unit separators “;” (semicolons) are required to delimit multiple com-

mands or queries in a single program message (string).

• In serial mode, the ! (exclamation point) character acts as the device clear command. It is

sent as a single character (no terminator) and should never otherwise appear in a message.

• The System parses commands as explained in Command Processing (page 4-7)

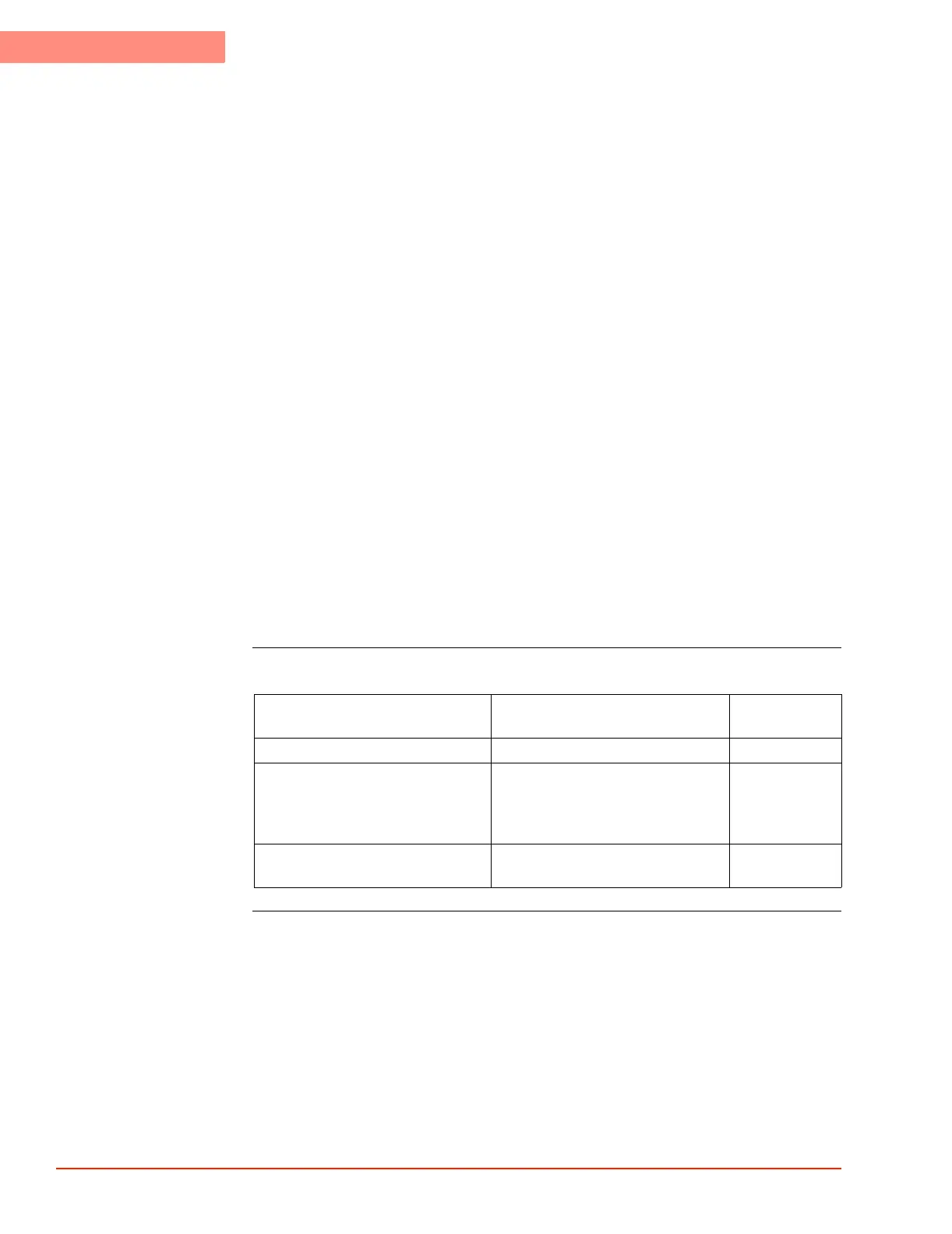

Command Examples

Description From Host to System System

Returns

Read the current temperature. TEMP?<LF> 25<LF>

Set the temperature setpoint to

25 °C, the “at temperature” window

to 3 °C, and the soak time to 15

seconds.

SETP 25;WNDW 3;SOAK 15<LF>

Read the setpoint and the current

temperature.

SETP?;TEMP?<LF> 25;24.9<LF>

Loading...

Loading...