80

CTV-SVU01G-EN

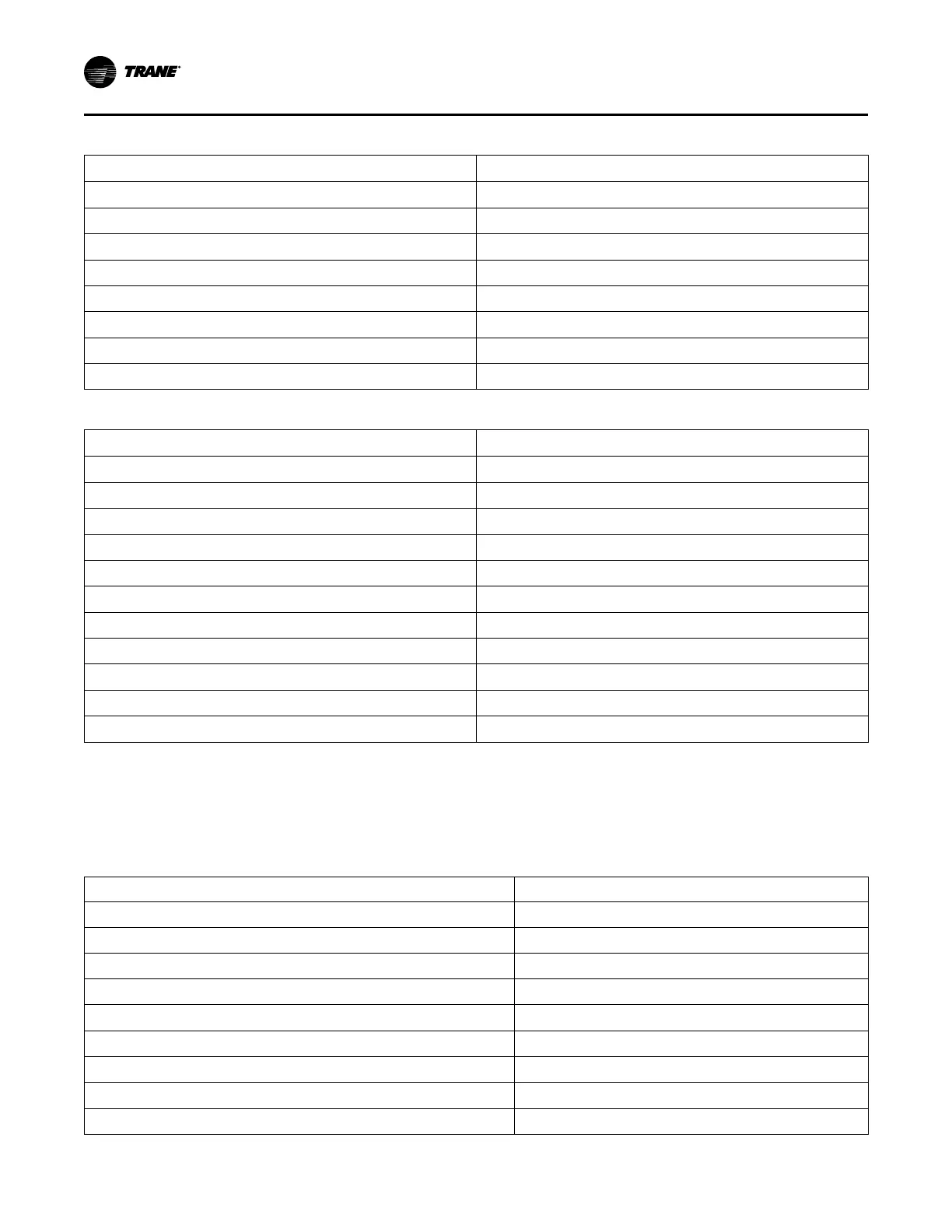

Table 56. Motor (continued)

Report item

Unit

Starter Power Demand (Ckt1 and Ckt2)

XXXX kW

Starter Load Power Factor (Ckt1 and Ckt2)

XX.X

Motor Winding Temp 1 (Ckt1 and Ckt2)

XXX.X °F/°C

Motor Winding Temp 2 (Ckt1 and Ckt2)

XXX.X °F/°C

Motor Winding Temp 3 (Ckt1 and Ckt2)

XXX.X °F/°C

AFD Frequency (Ckt1 and Ckt2)

XX Hz

AFD Speed (Ckt1 and Ckt2)

XXXX RPM

AFD Transistor Temp (Ckt1 and Ckt2)

XXX.X °F/°C

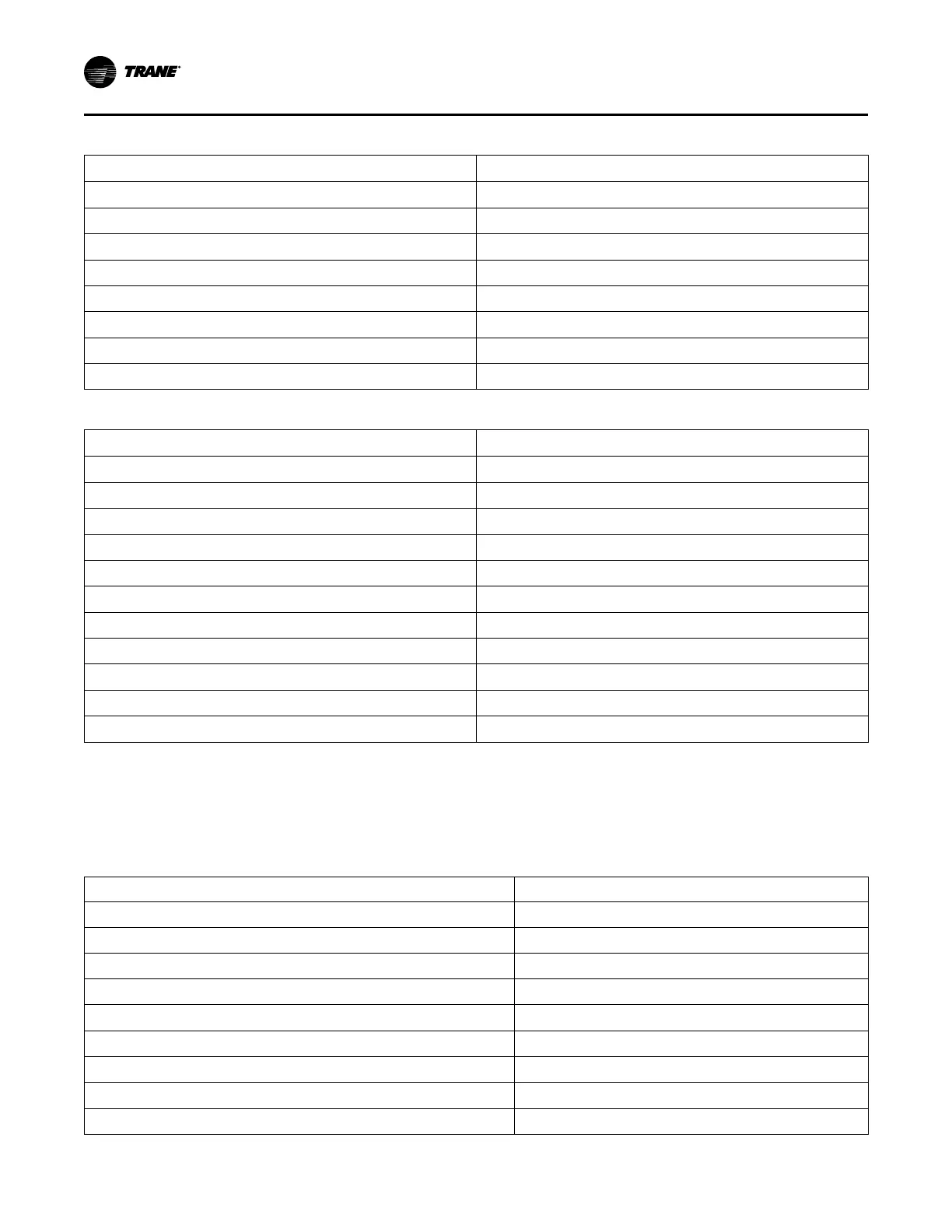

Table 57. Purge

Report item

Unit

Time Until Next Purge Run (Ckt1 and Ckt2)

XXX.X min

Daily Pumpout—24 Hours (Ckt1 and Ckt2)

XXX.X min

Average Daily Pumpout—7 Days (Ckt1 and Ckt2)

XXX.X min

Daily Pumpout Limit (Ckt1 and Ckt2)

XXX.X min

Chiller On—7 Days (Ckt1 and Ckt2)

XXX.X min

Pumpout Chiller On—7 Days (Ckt1 and Ckt2)

XXX.X min

Pumpout Chiller Off—7 Days (Ckt1 and Ckt2)

XXX.X min

Pumpout—Life (Ckt1 and Ckt2)

XXX.X min

Purge Rfgt Compressor Suction Temp (Ckt1 and Ckt2)

XXX.X °F/°C

Purge Liquid Temp (Ckt1 and Ckt2)

XXX.X °F/°C

Purge Carbon Tank Temp (Ckt1 and Ckt2)

XXX.X °F/°C

ASHRAE Chiller Log

NNoottee:: The ASHRAE Chiller Log contains those items recommended by ASHRAE Std 147 Standard

147-2002, Reducing Release of Halogenated Refrigerants from Refrigeration and Air-

Conditioning Equipment and Systems.

Table 58. ASHRAE Chiller Log data

Data name Value

Current Date/Time User-selected date/time format

Chiller Top Level Mode Dependent on chiller type

Evap Entering Water Temp

XXX.X °F/C°

Evap Leaving Water Temp

XXX.X °F/C°

Evap Water Flow Status

Flow/No Flow

Evap Differential Wtr Press

XXX.X PSI/kPa

Approx Evap Water Flow XXX.X gpm/lpm

Calculated Chiller Capacity

XXXX tons/kW

Refrigerant Type

R123

AAppppeennddiixx BB:: DDaattaa ffoorr CCeennTTrraaVVaacc DDuupplleexx CChhiilllleerrss

Loading...

Loading...