Phaser 6125/6130 Color Laser Printer Service Manual 2-37

Theory of Operation

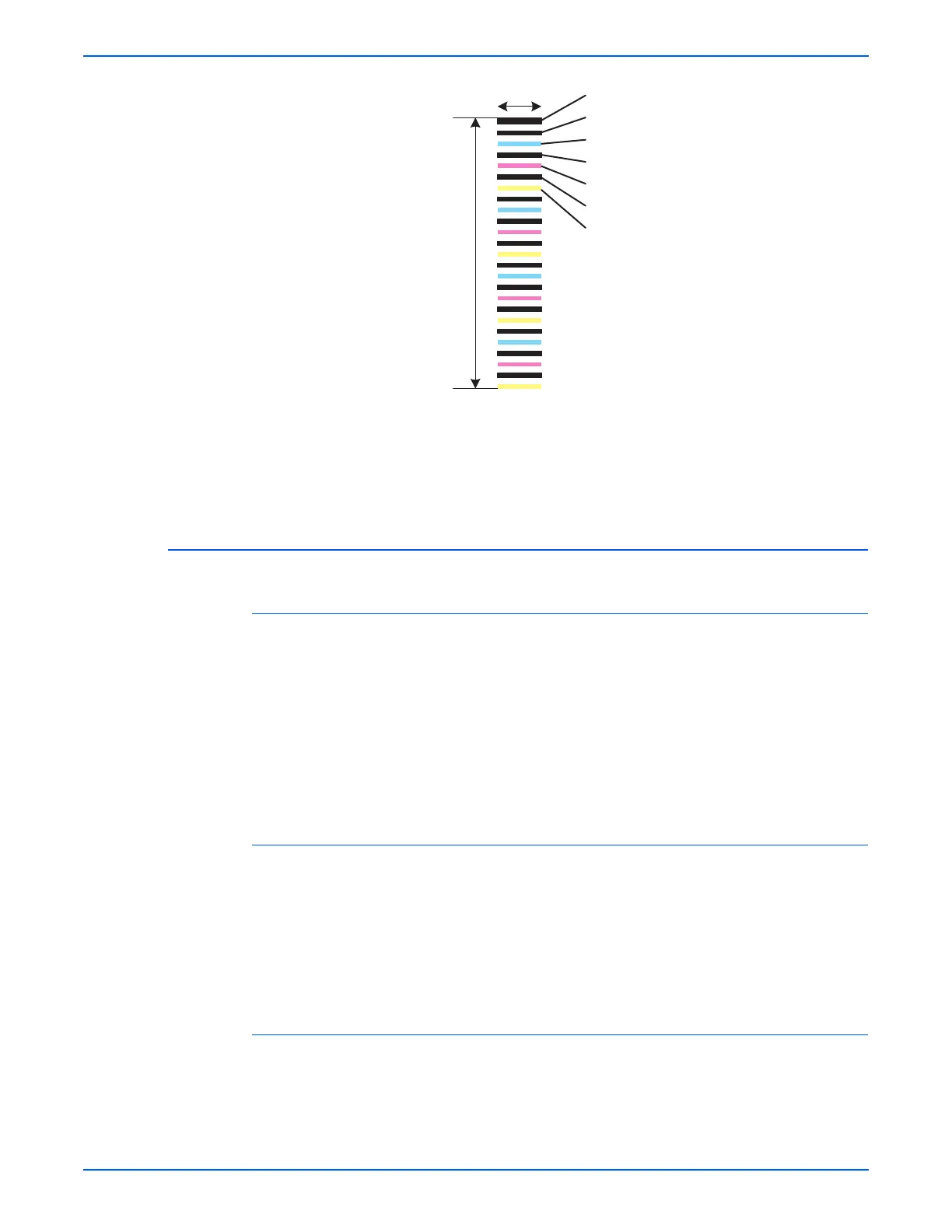

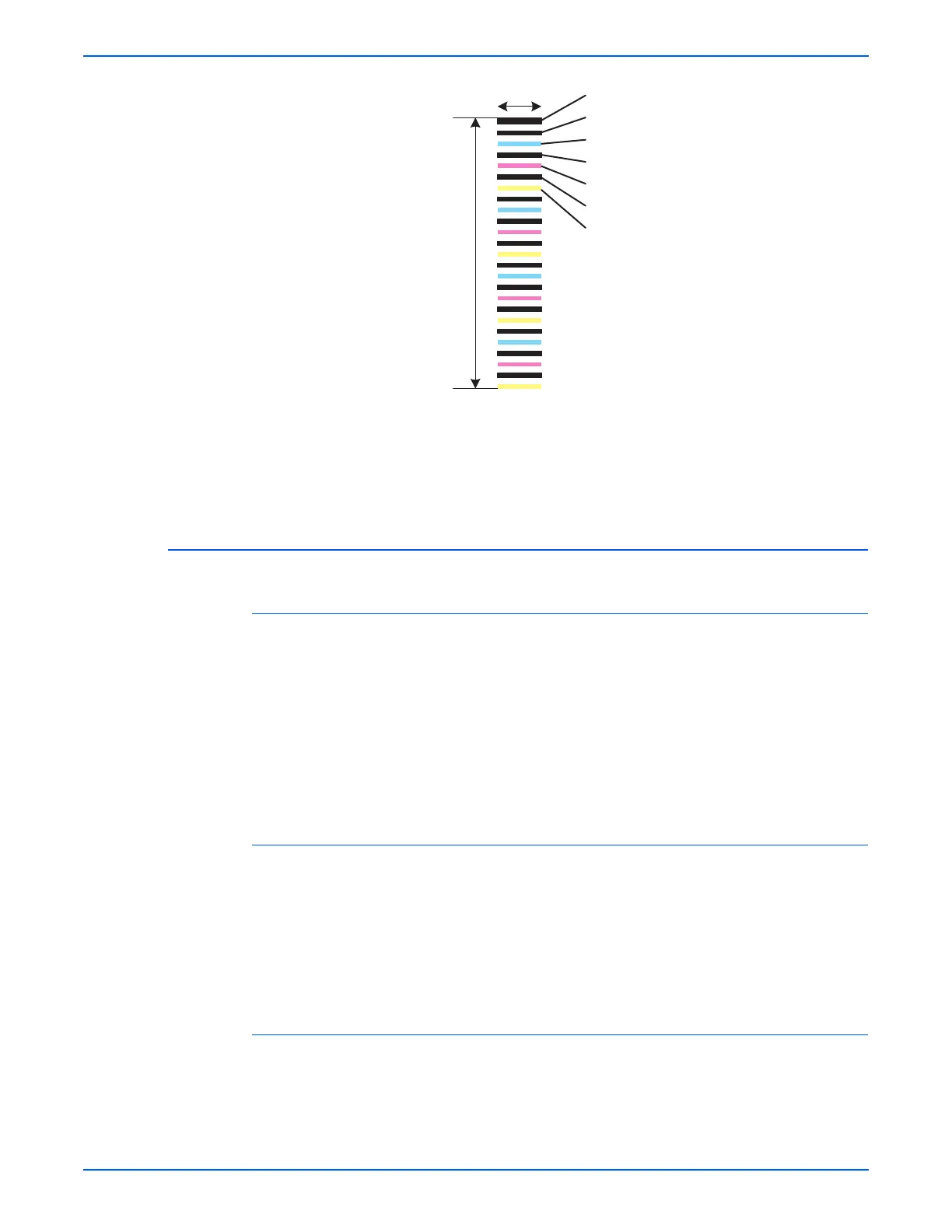

3. The ADC Sensor reads the patch density.

4. The amount of registration shift is calculated from the threshold value

determined in step 1 and the patch density measured in step 3.

5. The Laser Unit write timing is changed according to the amount of

registration shift.

Fuser Control

Fuser Temperature Control

After the target temperature is set, the Heat Roller surface temperature is

controlled by turning the Heater Lamp On/Off.

Temperature of individual area of the Heat Roller is detected by the Fuser

Non-Contact Sensor (NCS) in the middle of the Heat Roller and the Temp

Sensor at the edge of it.

The target temperature set up varies depending on the time of Warm-up,

Printing, or Process Control. The target set temperature is changed based on

the printer’s interior temperature detected by the Humidity Sensor.

Cool Down

As printing continues, the distribution of temperature in the Heat Roller

becomes uneven in both the paper feed and non-paper feed areas. Cooling

Down suspends paper feeling for a certain period of time so that the Heat

Roller temperature distribution can be uniform.

When the temperature of the Heat Roller edge is high, cooling down is

performed to lower the temperature to the target value.

Fuser NCS Sensor Warm-Up

The Fuser Non-Contact Sensor at the center of the Heat Roller loses its

accuracy when the temperature of the sensor itself is below -5° C. Therefore,

the sensor is warmed up when the temperature is below -5° C.

10 mm

About One Half

Turn Of Belt

s6180-290

K

K

C

K

M

K

Y

Loading...

Loading...