5 LIST OF PERIODIC INSPECTIONS AND MAINTENANCE

OPERATIONS

• The table below indicates the maintenance intervals to be respected for optimum operation of

the machine. Read the machine's time counter every day to check whether a procedure should be

implemented.

• The inspection sheets provided at the end of this manual enable you to keep a trace of the

maintenance operations carried out.

IMPORTANT

These are frequencies : for examplen the operations to be carried out every 50 hours must

be carried out at 50h, 100h, 150h, 200h, etc.

• Certain intervals may vary if a hydraulic hammer is used. Refer to the corresponding notes.

Note

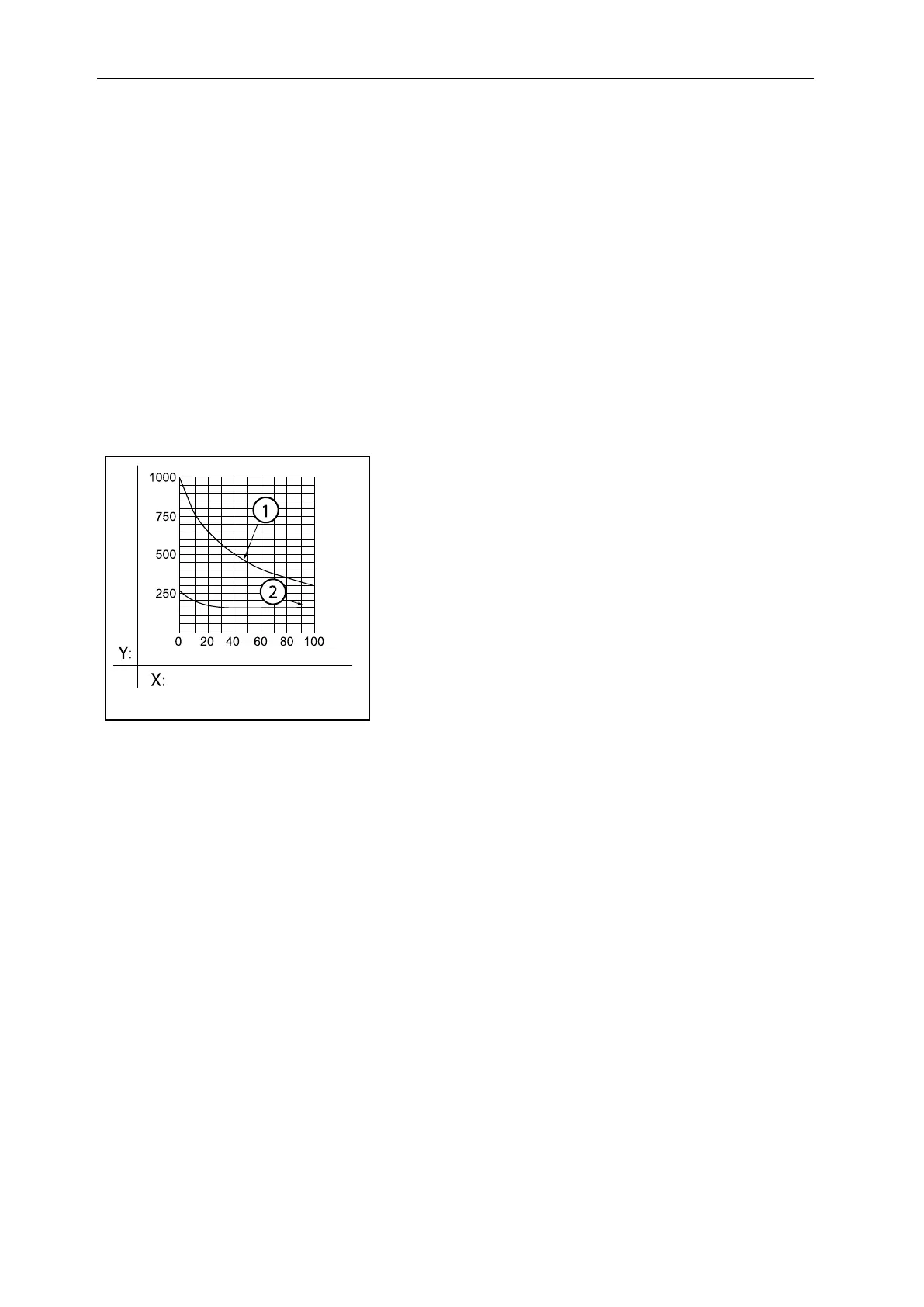

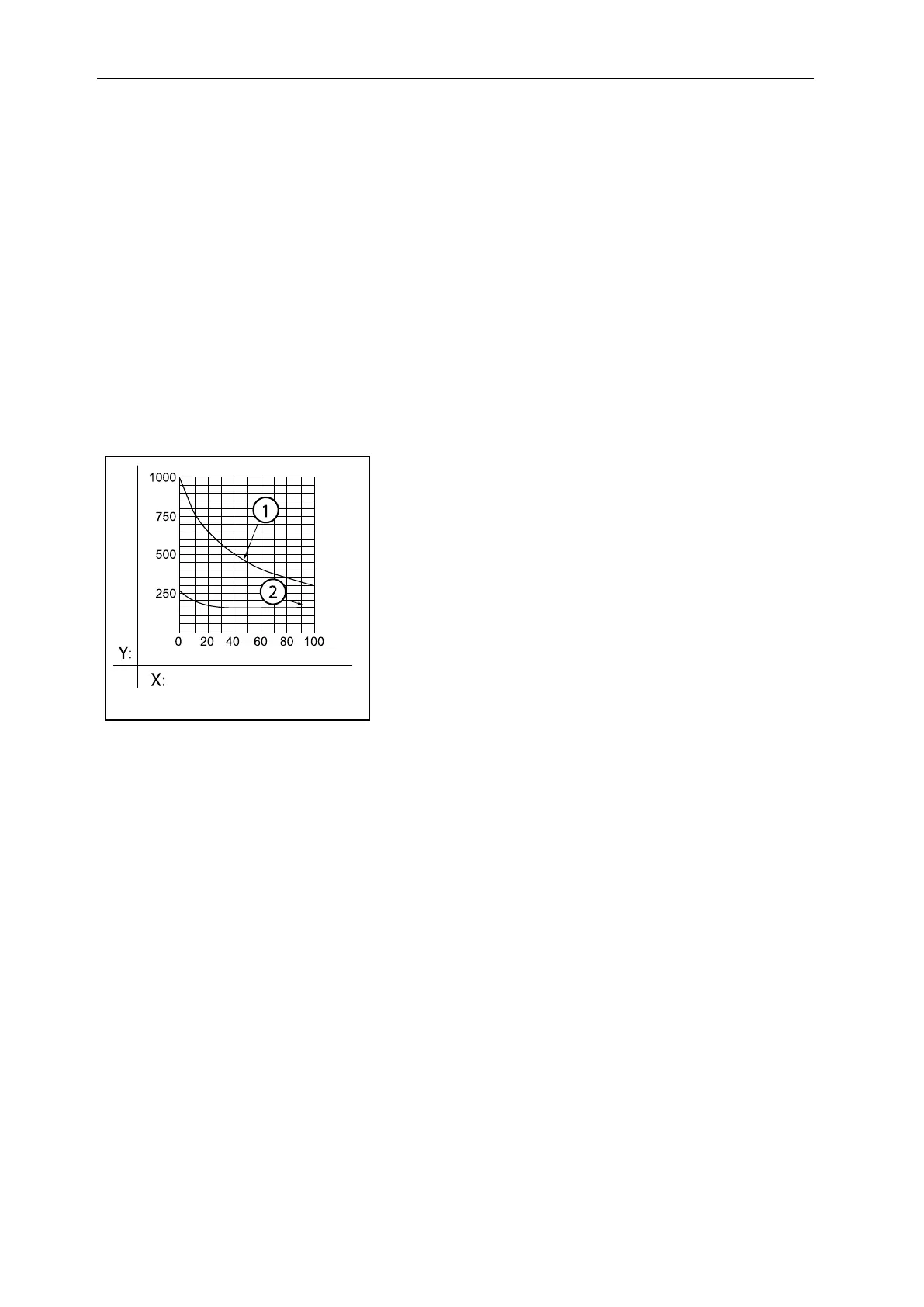

• If a hydraulic hammer is used, the re-

turn filter must be replaced after 100 or

150 hours of service for a new machine,

then according to the diagram opposite.

• The hydraulic oil must be replaced

more frequently if a hydraulic hammer is

used. Comply with the diagram opposite.

1 = Hydraulic oil

2 = Hydraulic oil return filter

X = Hydraulic hammer usage rate (%)

Y = Replacement interval (h)

139

Loading...

Loading...