6 Maintenance by the operator

150

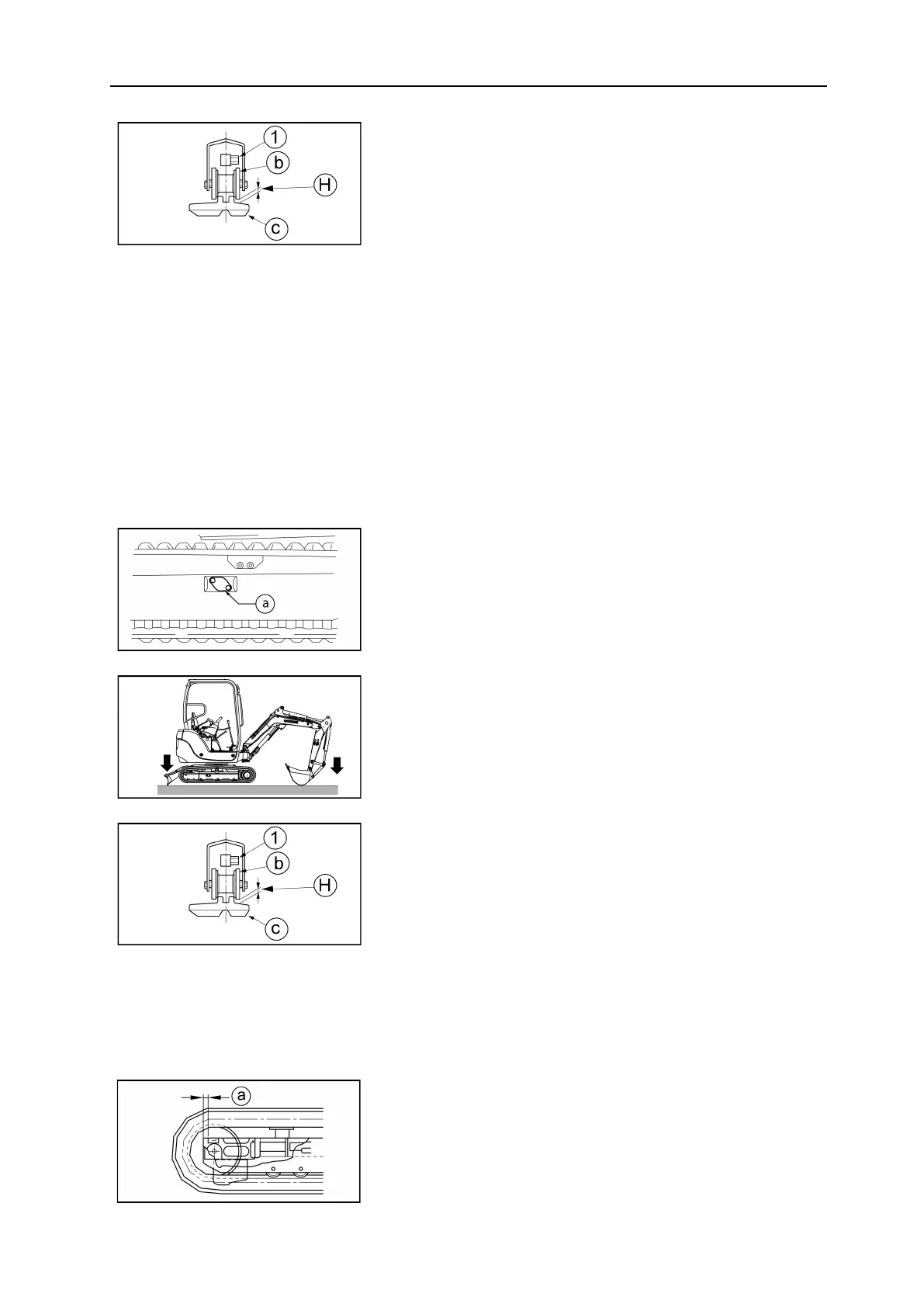

3. Check the tension. The play H between the external

rolling surface of the second track roller on the tightener

rooler and the internal surface of the track must be 8 ~

13 mm.

1 = Greaser

b = Track roller

c = Track

• If the tension is incorrect, follow the procedures given in the following chapters to increase

or release the track tension.

IMPORTANT

Perform a task with a relaxed track link may derail the track or cause premature wear of

the undercarriage.

6.4.4 Increasing the tension

1. Prepare a grease pump.

2. Loosen the two screws and rotate the bottom cover to

access the lubrication nipple.

a = Cover

3. Raise the machine with the equipment by activating

the command lever.

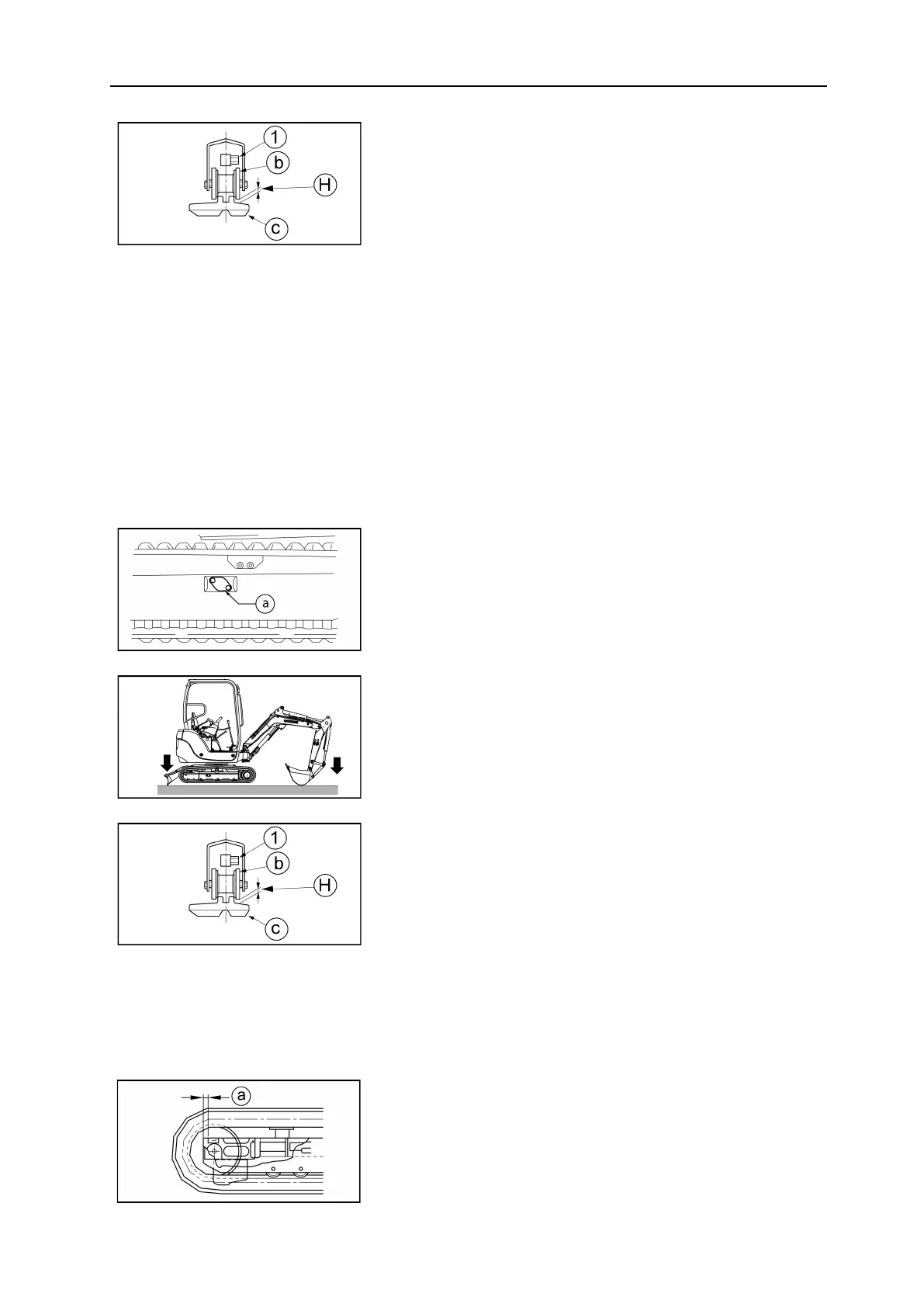

4. Using the grease pump, inject grease with the greaser

so that the play H is between8 ~ 13 mm.

1 = Greaser

b = Track roller

c = Track

5. Proceed with the track tensioning. To check that the tension is correct, put the machine down

and move it gently forwards and back.

6. Check the tension again. If it is still not correct, adjust it again.

7. Re-install the cover.

• The tension may be adjusted until the distance A is

reduced to 0. If the voltage is still insufficient, the track

must be replaced due to excessive wear. Contact your

dealer for repair.

• If the tension is weak, even after grease is injected,

the track must be replaced or a system tension check must

be performed. Contact your dealer.

Loading...

Loading...