6 Maintenance by the operator

152

6.5 Steel track maintenance

6.5.1 Checking the condition of the tracks

• The wear to the track pins and pegs depends on the working conditions and the nature of the

ground. Check the track tension regularly to maintain suitable tension.

• Check and adjust the track tension under the same conditions as the operating conditions (for

example, muddy conditions if the task is carried out on muddy ground).

• To find out whether the track must be replaced, repaired or you can continue to use it, contact

your YANMAR dealer.

6.5.2 Track replacement

• If a track (or both tracks) needs to be replaced, contact your dealer.

6.5.3 Tension check

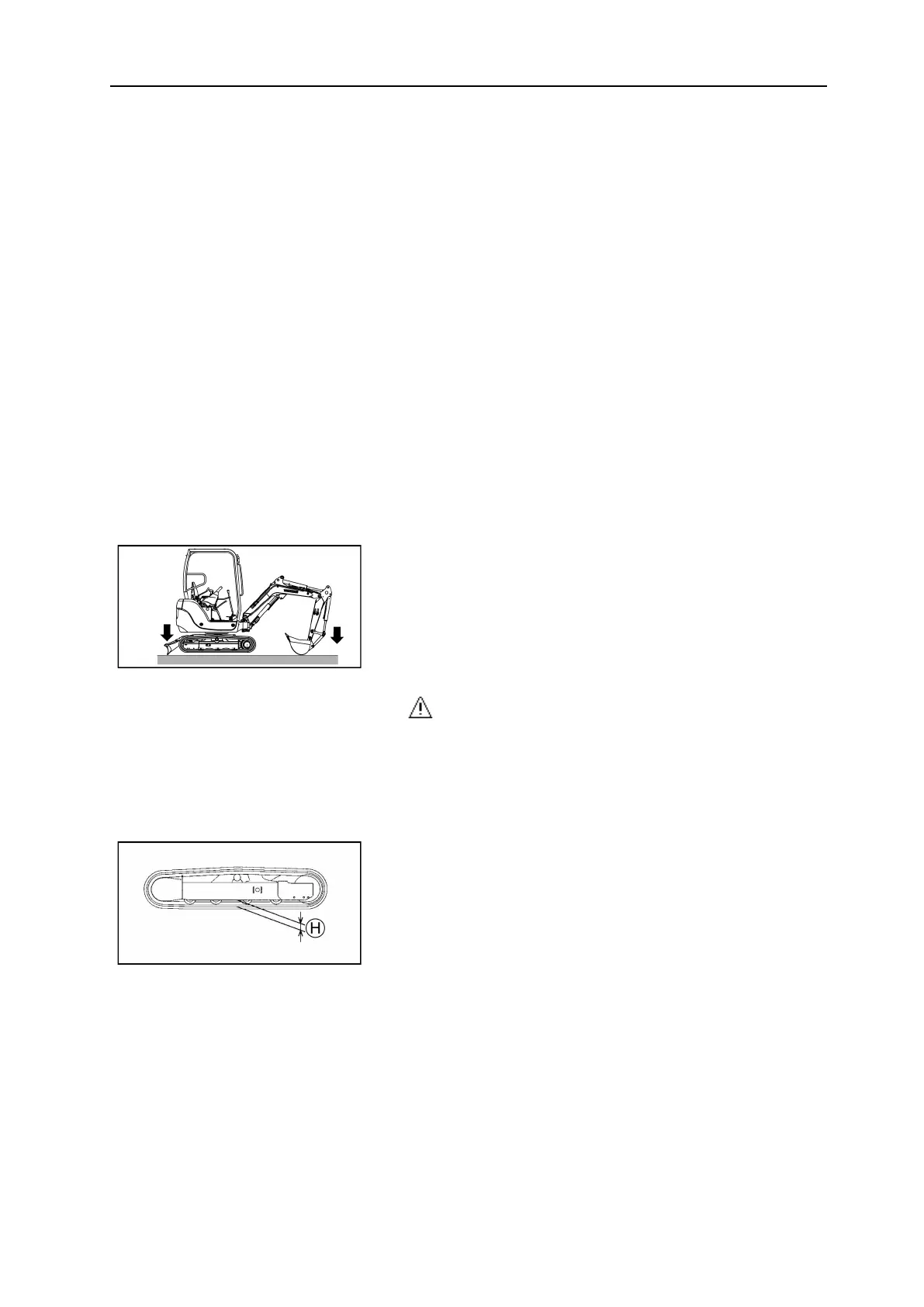

1. Raise the machine with the equipment by ac-

tivating the command lever.

WARNING

Do not support the machine with the accessory only. The command levers may move or hy-

draulic oil may spill accidentally and cause the machine to fall.

When the machine is checked or adjusted by two people, one of them must commission the

machine according to the signals given by the other person.

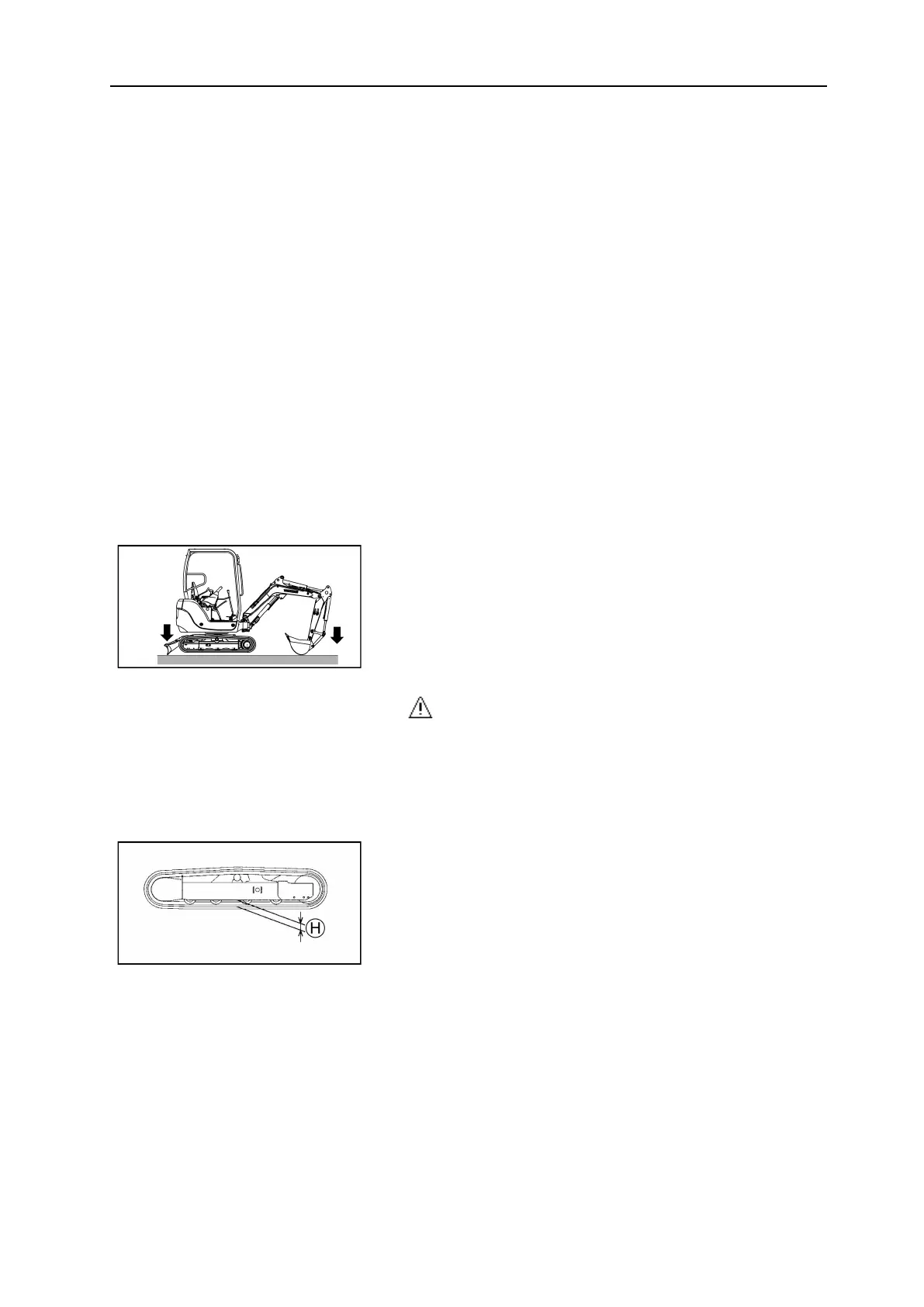

2. Check the tension. The play between the

lower part of the lower chassis and the internal

side of the machine must be 105 ~ 115 mm.

3. If the tension is incorrect, follow the proce-

dures given in the following chapters to in-

crease or release the track tension.

IMPORTANT

Perform a task with a relaxed track link may derail the track or cause premature wear of

the undercarriage.

Loading...

Loading...