Loading...

Loading...

Do you have a question about the Zetor MAJOR CL and is the answer not in the manual?

Basic rules for safe tractor operation and compliance.

Procedures and precautions for starting the tractor engine safely.

Operational practices for safe driving and handling of the tractor.

Factors increasing rollover risk and prevention methods.

Guidelines to prevent fires during operation and maintenance.

Daily checks and maintenance tasks for the tractor's safety.

Safe operating procedures for tractors equipped with front end loaders.

Procedure for checking and maintaining the engine oil level.

Checks for leaks and coolant level in the engine cooling system.

Display of operational data, fault notifications, and warning indicators.

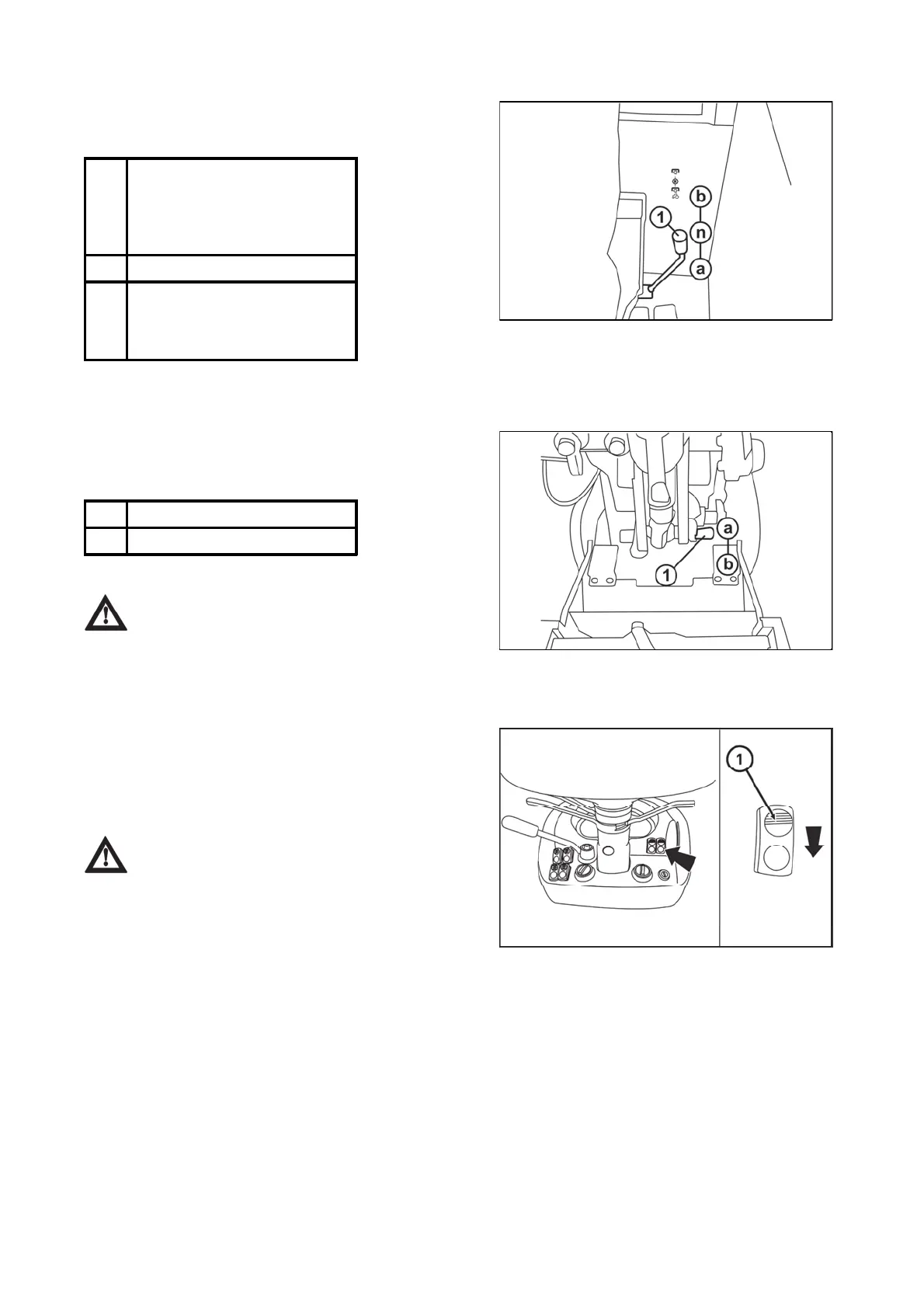

Identification and operation of tractor pedals and the differential lock.

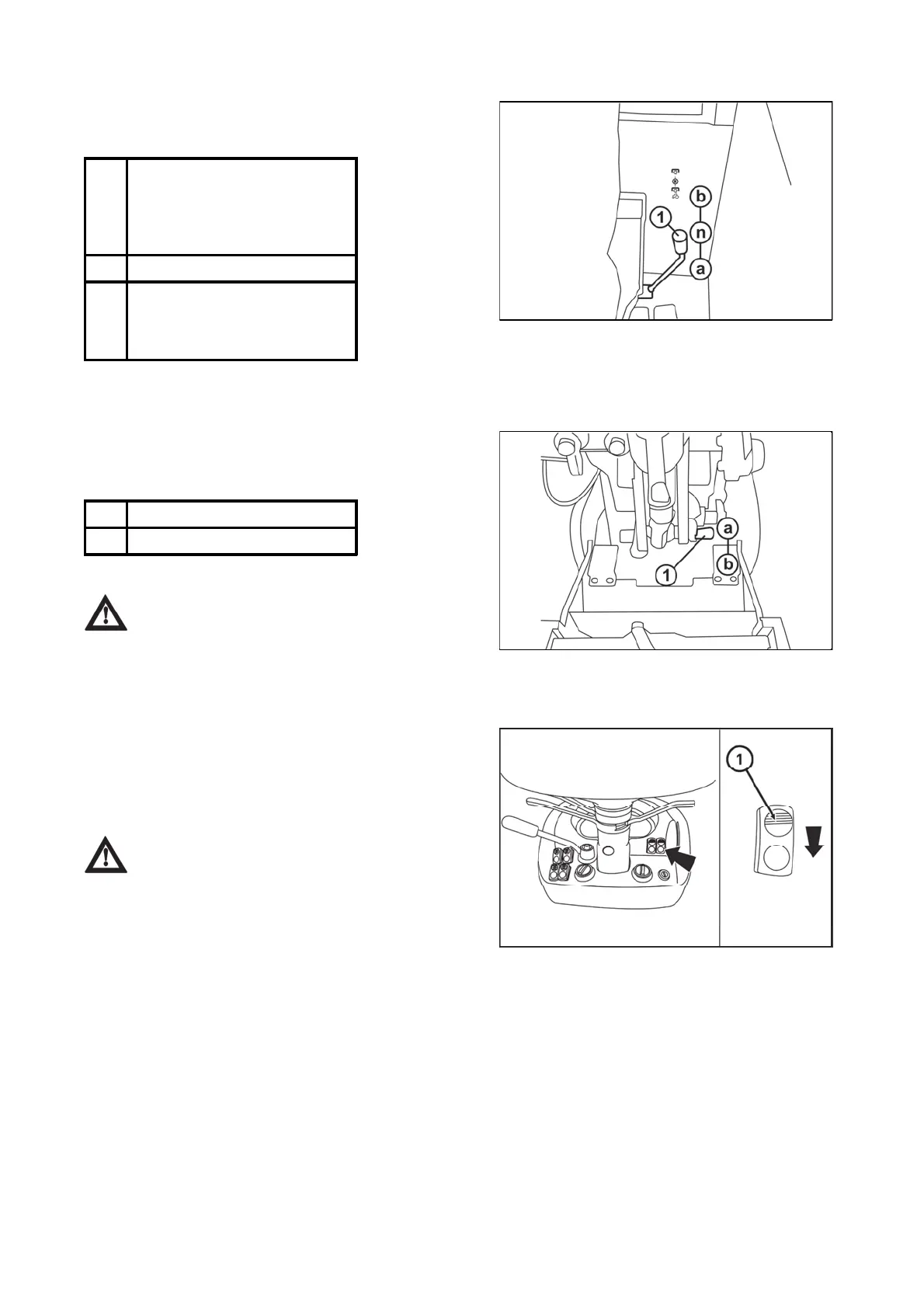

Operation of gear shifting, reversing levers, and PTO shaft controls.

Pre-start checks and procedures for the engine.

Step-by-step guide to starting the tractor engine safely.

Troubleshooting steps if the engine fails to start.

Interpretation of dashboard warning lights, error codes, and signals.

Step-by-step guide for driving the tractor away smoothly.

Procedures for engaging and disengaging the differential lock.

Operation and connection of foot brake pedals for braking.

Procedures for stopping the tractor using the manual brake and engine shutdown.

Core principles for breaking in a new tractor for the first 100 hours of operation.

Safe operation, connection, and use of PTO shafts and their covers.

Identification and function of PTO shaft control levers, buttons, and indicators.

Specifications and operating procedures for the front PTO shaft.

Overview of hydraulic system components, pump, and pressure.

Controls for three-point linkage adjustment (position, mixed, power).

System for connecting external hydraulic devices via quick couplers and control elements.