What to do if the Allen-Bradley Controller process value cannot reach the second peak?

- JJennifer WellsAug 2, 2025

If the process value is unable to reach the second peak, consider increasing the deviation or the step value.

What to do if the Allen-Bradley Controller process value cannot reach the second peak?

If the process value is unable to reach the second peak, consider increasing the deviation or the step value.

What to do if Allen-Bradley Micro830 Controller process value is not able to reach 'first peak'?

If the process value is unable to reach the first peak, consider reducing the deviation or increasing the step value.

What to do if the Allen-Bradley Micro830 Controller process value doesn't reach the first peak in time?

If the Allen-Bradley Controller process value doesn't reach the first peak in time, increase the ATDynamSet value.

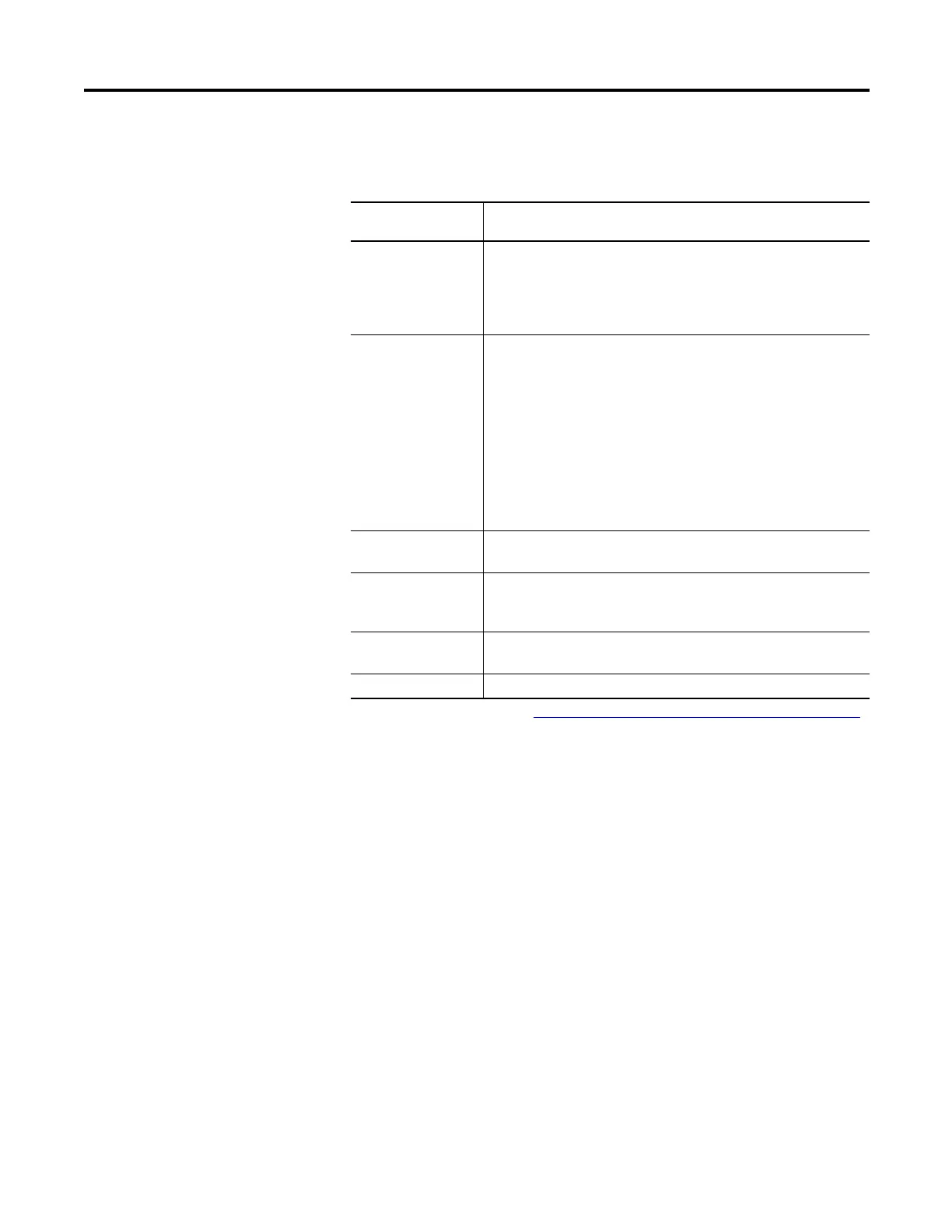

| Brand | Allen-Bradley |

|---|---|

| Model | Micro830 |

| Category | Controller |

| Language | English |

Provides an overview of the Micro830, Micro850, and Micro870 controllers' brick-style design and expandability.

Details the Micro830 10/16-point controllers, including their status indicators and physical layout.

Describes the Micro850 24-point controllers, including status indicators, controller description, and terminal blocks.

Details the Micro870 24-point controllers, including status indicators, controller description, and terminal blocks.

Explains that standard USB A Male to B Male cables are used for programming controllers.

Lists available embedded serial port cables and their specifications.

Describes the 10/100 Base-T Ethernet port on Micro850 and Micro870 controllers and its LED indicators.

Introduces Connected Components Workbench software for programming, configuration, and HMI design.

Explains features like Run Mode Change (RMC) and Run Mode Configuration Change (RMCC) for modifying controllers.

Provides guidance on installing controllers in industrial enclosures and minimizing electrical noise.

Covers important safety aspects including hazardous location approvals and power disconnection.

Provides mounting dimensions for Micro830 10/16, 24, and 48-point controllers.

Details the procedure for mounting modules onto DIN rails using latches and end anchors.

Explains the process of panel mounting controllers using M4 screws and hole spacing tolerances.

Illustrates the front and side views of Micro830/850/870 24-point controllers, including I/O slots.

Covers essential wiring requirements and recommendations, including power disconnection and current calculations.

Explains the importance of surge suppressors for inductive loads to protect controller output contacts.

Provides methods to reduce electrical noise, such as using NEMA enclosures and proper grounding.

Offers guidelines for wiring analog channels, including isolation, shielding, and minimizing noise.

Lists Allen-Bradley surge suppressors suitable for relays, contactors, and starters, categorized by device.

Details the requirement to mount the controller on a well-grounded panel and provides reference for wiring guidelines.

Illustrates wiring diagrams for Micro800 controllers, covering sinking/sourcing inputs and high-speed inputs/outputs.

Explains the embedded serial port wiring, pinout table, and important considerations for GND connection.

Lists supported communication protocols like Modbus RTU, CIP Serial/Symbolic, EtherNet/IP, and ASCII.

Explains the Modbus RTU protocol, its master/slave capabilities, and configuration steps.

Explains Modbus TCP communication over Ethernet, sharing mapping features with Modbus RTU.

Covers CIP Symbolic communication over Ethernet/IP and Serial ports for HMI connectivity.

Guides on configuring the Serial Port driver as CIP Serial, Modbus RTU, or ASCII in Connected Components Workbench.

Guides on configuring Ethernet settings, including IP address, subnet mask, and port settings.

Outlines rules for validating IP address configurations, including valid ranges and exclusions.

Provides an overview of the Micro800 controller's scan cycle, program execution order, and naming conventions.

Explains factors affecting controller load and performance, such as interrupts and communication.

Recommends using STI for periodic program execution and warns against using system variables for precise timing.

Explains how user-created variables are retained after a power cycle across different Micro800 controllers.

Explains PTO functionality for generating pulses to control motion devices like servo drives.

Introduces the elements of Micro800 motion control, including Pulse Train Outputs, Axis, and Function Blocks.

Categorizes function blocks into Administrative and Movement types for controlling motion axes.

Provides general rules for working with motion function blocks, covering parameters, limits, and error handling.

Visually represents the states of a motion axis and the transitions between them based on function block execution.

Defines parameters for setting boundary points for axes, including Hard Limits, Soft Limits, and PTO Pulse Limits.

Describes three types of motion stops: Immediate Hardware Stop, Immediate Soft Stop, and Decelerating Soft Stop.

Provides a table of error codes shared by motion control function blocks and their corresponding axis status errors.

Guides on configuring motion axes, including adding, updating, deleting, and monitoring axes.

Introduces High-Speed Counter (HSC) features, hardware, and instructions for Micro830/850/870 controllers.

Explains the Programmable Limit Switch (PLS) function for configuring HSC as a rotary cam switch.

Defines High-Speed Counter (HSC) for detecting fast pulses and initiating control operations based on counts.

Details HSC input mapping for Micro830/850/870 controllers across different models and modes.

Describes the HSC Mode variable that sets the High-Speed Counter to one of ten operation types.

Describes the HSC function block for starting/stopping counting, refreshing status, and reloading settings.

Guides on configuring High Speed Counter for PLS operation using multiple high and low presets.

Guides on testing the HSC program by entering debug mode and observing output values.

Prevents simultaneous configuration of the controller by multiple users, enforcing single session access.

Secures controller intellectual property and prevents unauthorized access by requiring a password.

Provides workflows for uploading, debugging, and downloading projects with password-protected controllers.

Explains how to set, change, and clear controller passwords using Connected Components Workbench.

Provides steps to recover access to a controller when the password is lost, involving firmware updates.

Introduces microSD card support for Micro800 controllers, including project backup, data log, and recipe functions.

Details project backup and restore functionality on Micro830/850/870 controllers using microSD cards.

Describes the data logging feature for capturing global and local variables with timestamps into a microSD card.

Explains the Recipe feature for storing and loading data to/from recipe files using the RCP instruction.

Guides on configuring data logs, creating ladder programs, building, downloading, and executing the DLG function block.

Provides steps to configure recipes, create ladder programs, build, download, and execute the RCP function block.

Provides specifications, ratings, and certifications for Micro830 controllers.

Details general specifications for Micro830 10-point controllers, including I/O, dimensions, and wire size.

Details environmental specifications such as temperature, humidity, vibration, and shock resistance.

Lists certifications such as UL, CE, RCM, KC, EAC, and EtherNet/IP conformance.

Details general specifications for Micro850 24-point controllers, including I/O, dimensions, and wire size.

Provides general specifications for Micro870 24-point controllers, including I/O, dimensions, and wire size.

Explains Modbus RTU and TCP mapping for Micro800 controllers, including big-endian configuration.

Illustrates configuring a PanelView Component HMI as Master to communicate with Micro800 as Slave via Modbus RTU.

Provides steps for configuring a PowerFlex 4M drive to communicate with Micro800 via Modbus RTU.

Guides on flashing controller firmware using Connected Components Workbench software release 10 or later.

Shows how to establish communication between RSLinx and Micro8xx controllers using the AB_VBP-x driver via USB.

Provides instructions on setting, changing, and clearing controller passwords using Connected Components Workbench.

Explains the two-step process of flashing firmware to Micro800 controllers using a microSD card.

Guides on creating an HSC project and variables in Connected Components Workbench.

Details assigning values to HSC variables like MyCommand, MyAppData, and MyStatus in the Local Variables table.

Guides on testing the HSC program by entering debug mode and observing output values.

Explains logical and physical forcing of I/Os, highlighting restrictions for special functions like HSC and Motion.

Introduces Run Mode Change for making small logic changes to a running project without disconnecting.

Explains fundamental properties of User Interrupts, including what they are and when they can occur.

Guides on configuring user interrupts and setting them as AutoStart from the Interrupts window.

Describes the user fault routine for cleanup before controller shutdown upon specific user faults.

Lists user interrupt instructions like STIS, UID, UIE, UIF, and UIC with their usage and page references.

Explains the STIS instruction for starting/stopping STI functions and changing time intervals.

Guides on using the STI function for time-critical control requirements and its operating sequence.

Details EII function configuration parameters, including EII Program POU and Auto Start settings.

Covers EII function status bits like Executing, Enable, and Lost, monitorable in User Program or CCW.

Provides diagrams and descriptions of status indicators for Micro830, Micro850, and Micro870 controllers.

Lists possible controller error codes and recommended recovery actions, accessed via Diagnostics page.

Provides a detailed list of error codes, their types, descriptions, and recommended actions for Micro800 controllers.

Provides steps for correcting recoverable and non-recoverable faults, including saving fault logs.

Presents a flowchart model for diagnosing and recovering from software and hardware problems in the microcontroller.

Compares IPIDCONTROLLER and PID function blocks, detailing common and specific parameters.

Explains the arguments used in the PID function block, including Enable, PV, SetPoint, and AutoManual.

Provides steps and requirements for performing the autotune process for PID controllers.

Analyzes autotune control output sequences and actions to take when autotune fails.

Shows sample PID code using Function Block Diagrams, including pre-defined and user-defined function blocks.

Lists power requirements for Micro830/850/870 controllers, plug-in modules, and expansion I/O.

Provides a formula and examples for calculating the total power consumption of the controller system.

Explains how to calculate external AC power supply loading, including sensor current and total system load.