24.14

Assembly notice for lubricated version:

•

While installation is basically a reversal of the re-

moval process, careful attention should be di-

rected toward the following:

•

Apply approximately 20 g (0.7 oz) of grease to

the tracks on the inside plate and install rollers

•

Lightly grease O-ring and install

•

Install spring clamp, sliders on transfer element

and grease the recesses in the sliders

•

PInsert transfer element

•

Check transfer element to ensure that it slids

without stiction

•

Secure variator cover

Fluids and lubricants:

Shell Retinax HDX2 ...... approximately 20 g (0.7 oz)

X

Torque specification:

Variator cover mount ...................................... 4 Nm

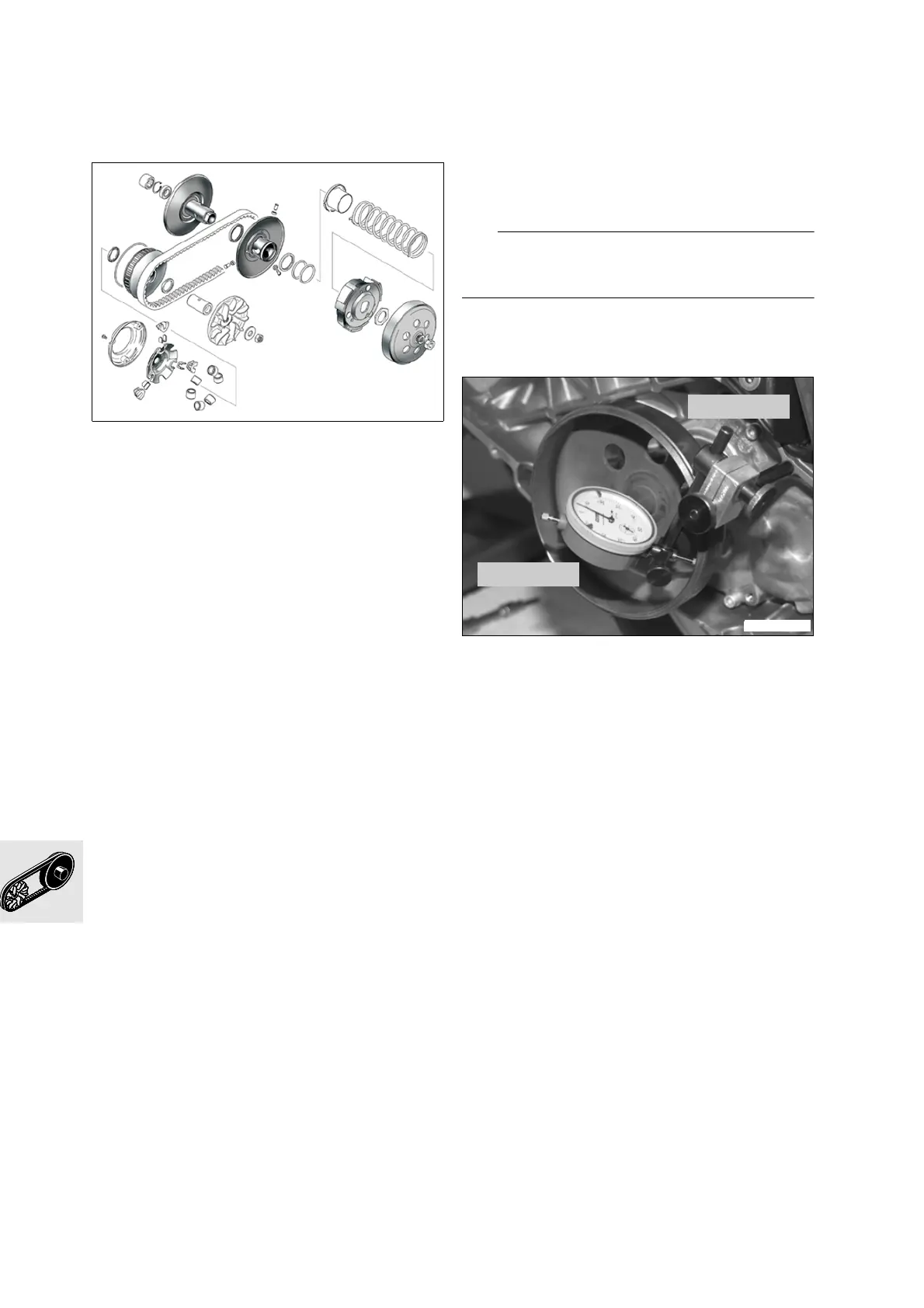

Dismantling, testing and assembling

drive variator

Checking individual components of

driven variator

For the sake of clarity, these illustrations show the

vehicle with the powertrain cradle removed

L

Note:

Dismantling is necessary only in the event of a mal-

function!

– Checking clutch (

a

21.5)

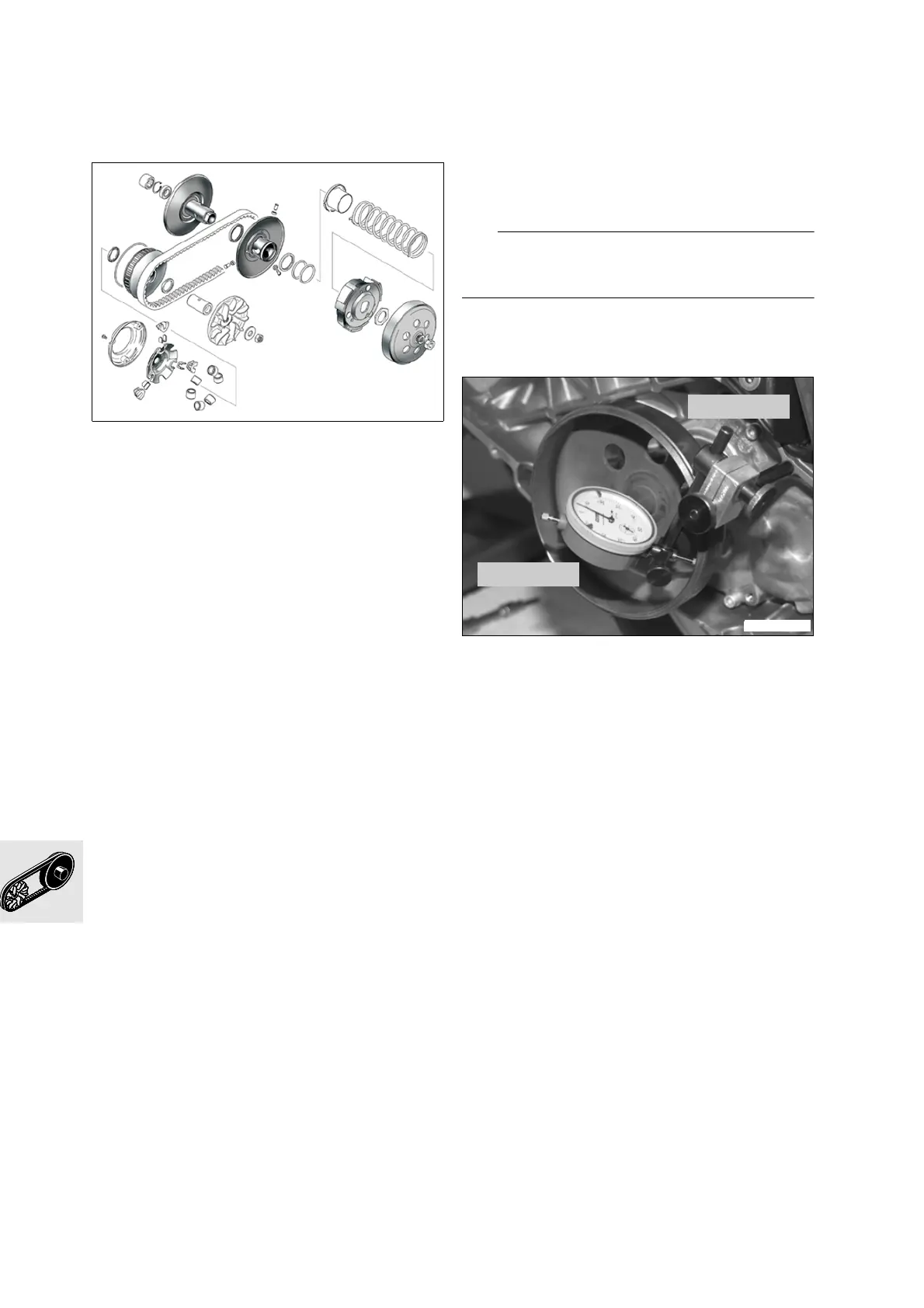

Check variator shaft

•

Check runout on variator shaft with dial gauge

and holder,

BMW No. 00 2 500

Wear data:

Runout .............................. max. 0.3 mm (0.0118 in)

C1111300

00 2 510

C1110530

00 2 500

Loading...

Loading...