Trouble Shooting Information for C7000VP series

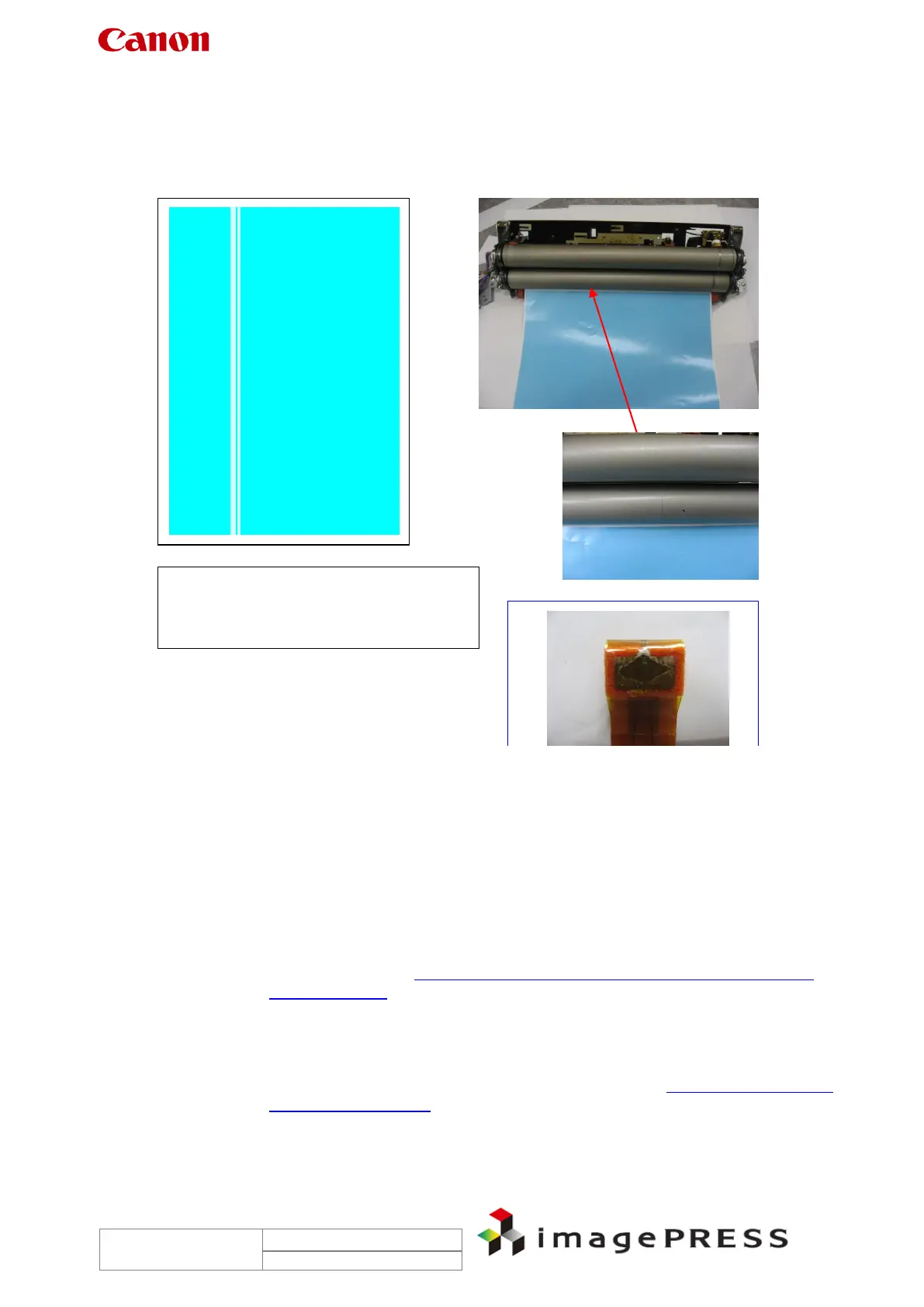

3.20 Streaks due to uneven gloss on the coated paper (sub scanning)

Description

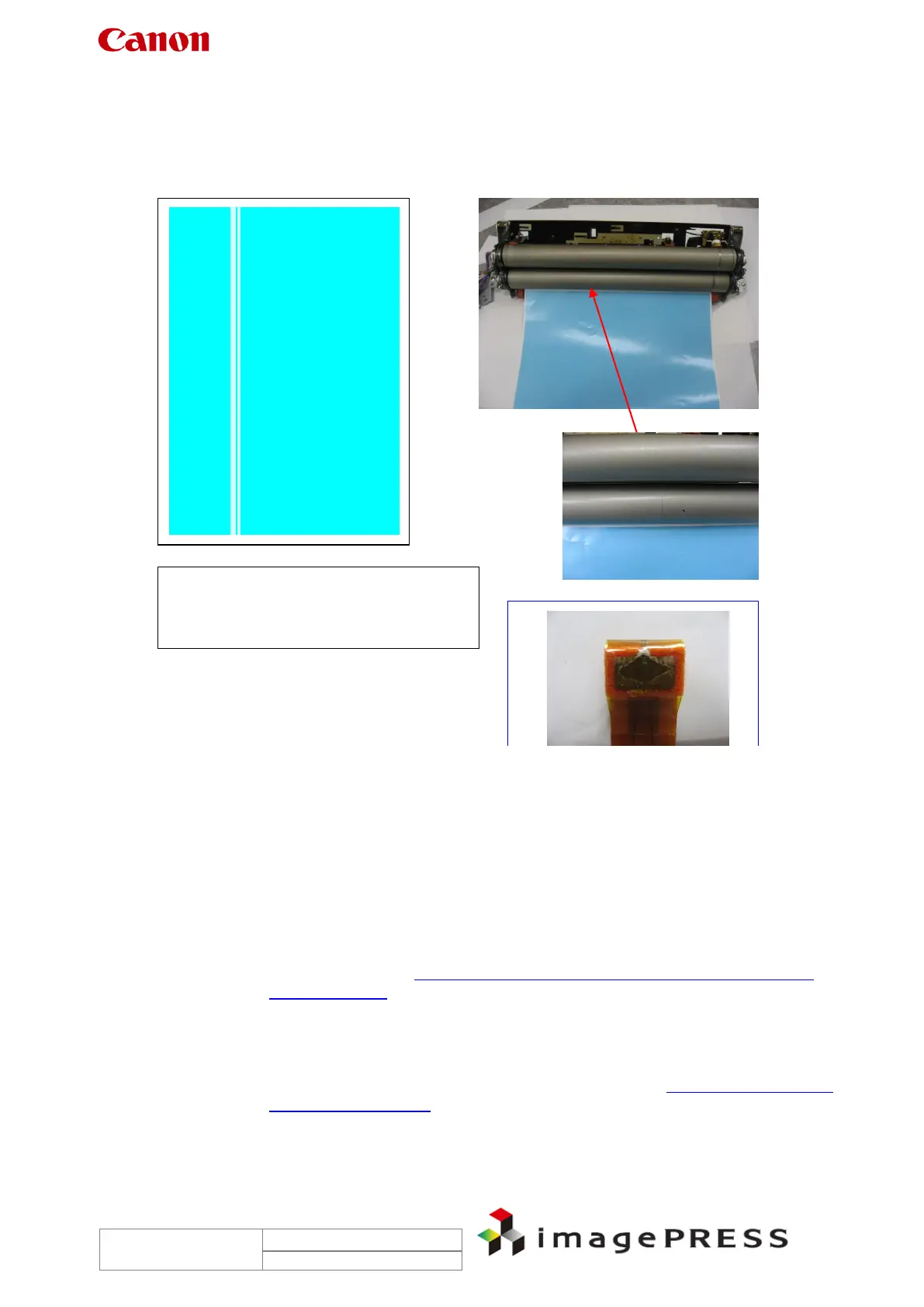

There are some reported instances from the field where uneven gloss looked like streaks due

to scratches on the lower external heating roller of the secondary fixing assembly.

Scratches on the roller are found on the portion coming in contact with the thermistor.

Field Remedy 1: When streaks appear lower gloss as compared with

other area

The external heating roller (FC7-0932) may reach the end of life. Check the part life.

Field Remedy 2: When streaks appear higher gloss as compared with

other area

The amount of wax applied to the external heating roller may be too much.

Solution 1: Perform the setting change to increase the frequency of the refresh roller

operation. (Refer to 5.1 Description on fixing roller refresh operation and its

execution timing)

As a negative effect, the roller life will be shortened. Also, depending on the

setting, the productivity will be degraded because the intervals between sheets

become longer.

Solution 2: Adjust the gloss of a custom paper type so that lower the overall gloss

becomes less noticeable the streaks become. Refer to ‘Adjusting the Gloss of

a Custom Paper Type’ in 6.1 Adjustments under [Registering/Editing Custom

Paper Types].

This illustration is a sample image. The streaks

look like void but are uneven glosses on the

actual image.

Thermistor surface in contact with the roller

Loading...

Loading...